Phosphorus-free cleaning agent

A cleaning agent and chelating agent technology, applied in the field of cleaning agents, can solve the problems of cleaning agent waste liquid discharge limitation, failure to meet environmental protection requirements, failure to meet the market, etc., to achieve improved corrosion inhibition, long service life, and excellent cleaning ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

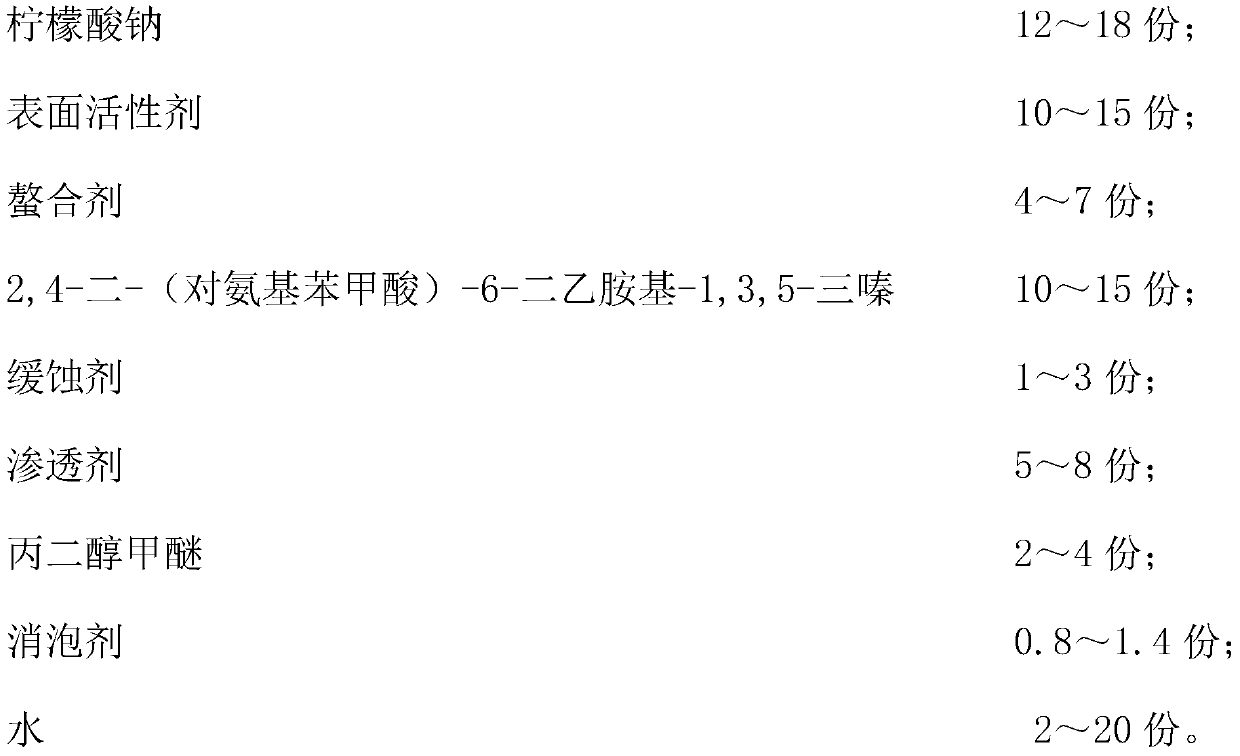

[0038] A kind of phosphorus-free cleaning agent, by weight, comprises following component:

[0039]

[0040] Surfactants include 20wt% alkyl dimethyl sulfopropyl betaine, 40wt% 1-carboxymethyl fatty imidazoline and 40wt% sodium palmitoleyl glutamate; chelating agent includes 24wt% sodium carboxylate, 32wt% Trialkylene tetraamine potassium lactate and 44wt% diethyl citrate; corrosion inhibitor is 1-hydroxyethyl-2-oleyl imidazoline; penetrant includes 40wt% secondary alkyl sulfate sodium, 24wt% sulfamic acid Sodium, 36 wt% N-benzylamine phenylenediamine; antifoaming agent including 32 wt% imidazoline laurate, 40 wt% polyoxyethylene polyoxypropylene pentaerythritol ether and 28 wt% hexanediol.

[0041] The preparation method of the phosphorus-free cleaning agent: according to the above-mentioned cleaning agent ratio, first add water, then add the cleaning agent according to the order of the formula under stirring, add the modified siloxane after stirring evenly, and stir evenl...

Embodiment 2

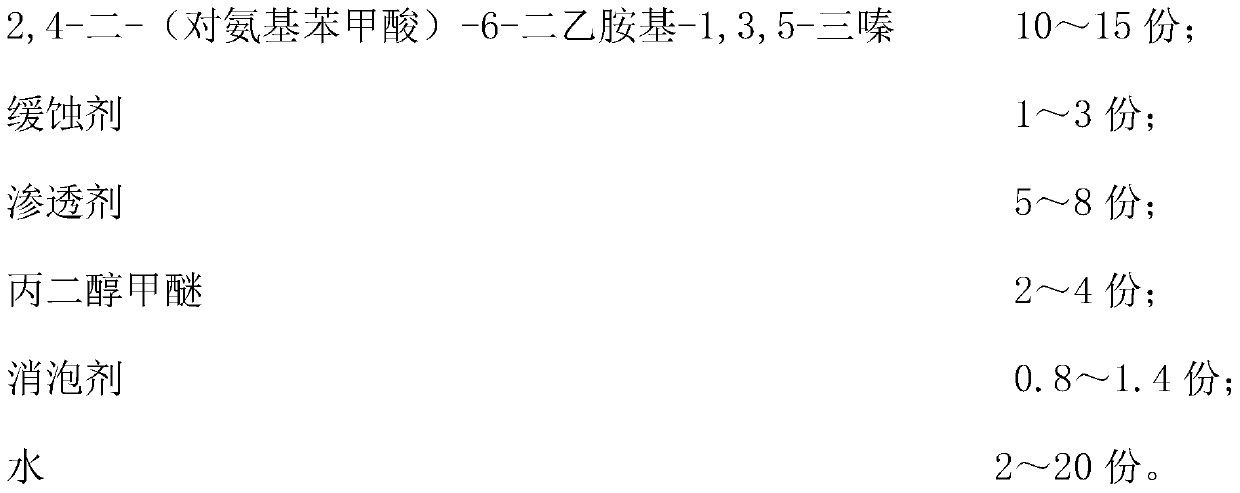

[0043] A kind of phosphorus-free cleaning agent, by weight, comprises following component:

[0044]

[0045]Surfactant comprises 25wt% alkyl dimethyl sulfopropyl betaine, 35wt% 1-carboxymethyl fatty imidazoline and 40wt% sodium palmitoleyl glutamate; Chelating agent comprises 26wt% sodium carboxylate, 32wt% Trialkylenetetramine potassium lactate and 42wt% diethyl citrate; corrosion inhibitor is mercaptobenzothiazole; penetrant includes 43wt% secondary alkyl sulfate sodium, 22wt% sodium sulfamate, 35wt% N-benzylamine Phenylenediamine; antifoaming agent comprising 33 wt% imidazoline laurate, 39 wt% polyoxyethylene polyoxypropylene pentaerythritol ether and 28 wt% hexanediol.

[0046] The preparation method of the phosphorus-free cleaning agent: according to the above-mentioned cleaning agent ratio, first add water, then add the cleaning agent according to the order of the formula under stirring, add the modified siloxane after stirring evenly, and stir evenly.

Embodiment 3

[0048] A kind of phosphorus-free cleaning agent, by weight, comprises following component:

[0049]

[0050] Surfactant includes 30wt% alkyl dimethyl sulfopropyl betaine, 40wt% 1-carboxymethyl fatty imidazoline and 30wt% sodium palmitoleyl glutamate; chelating agent includes 28wt% sodium carboxylate, 32wt% Trialkylenetetraamine potassium lactate and 40wt% diethyl citrate; corrosion inhibitor is bismuth molybdate; penetrant includes 44wt% secondary alkyl sulfate sodium, 24wt% sodium sulfamate, 32wt% N-benzylaminobenzene Diamine; antifoaming agent comprising 34 wt% imidazoline laurate, 40 wt% polyoxyethylene polyoxypropylene pentaerythritol ether and 26 wt% hexanediol.

[0051] The preparation method of the phosphorus-free cleaning agent: according to the above-mentioned cleaning agent ratio, first add water, then add the cleaning agent according to the order of the formula under stirring, add the modified siloxane after stirring evenly, and stir evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com