Concrete wastewater detection process

A technology for concrete and waste water, applied in the fields of flocculation/sedimentation water/sewage treatment, testing water, measuring devices, etc., can solve the problems of effective detection and recycling of waste water, and achieve the problem of not easy to be defective, improve early and late strength, and improve strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the embodiments of the present invention will be described below with reference to the accompanying drawings.

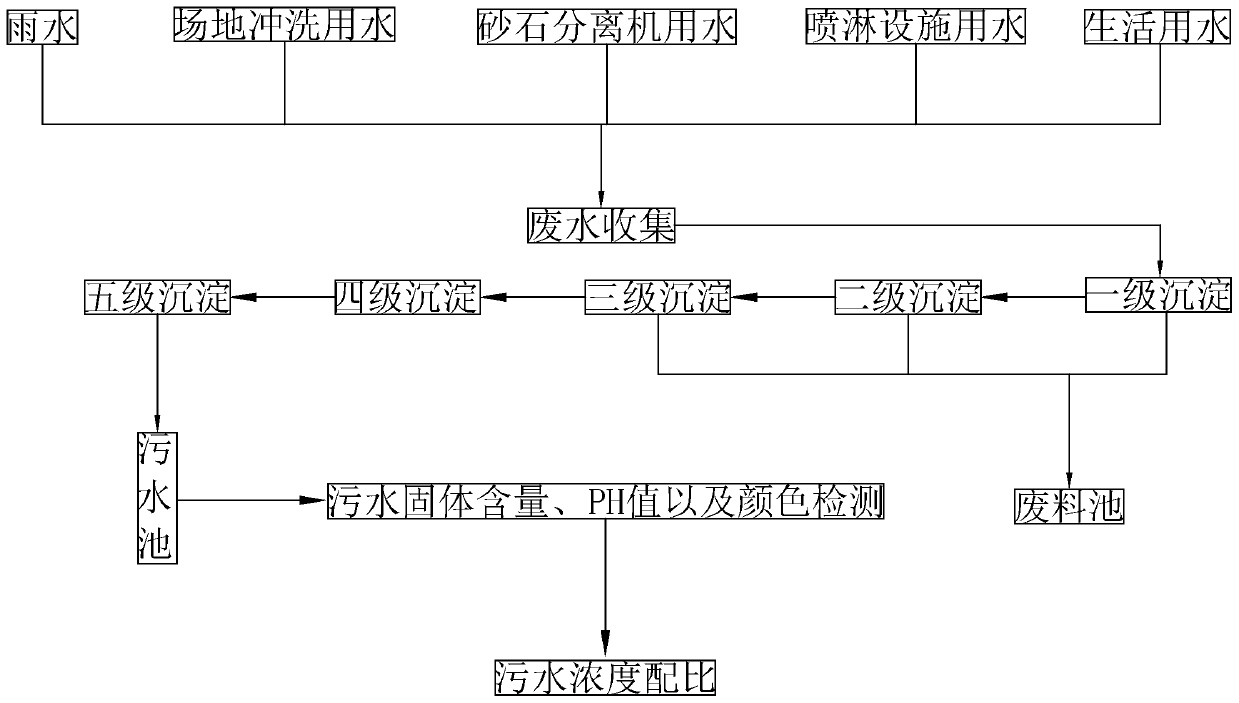

[0029] Such as figure 1 Shown, a kind of detection technology of concrete waste water, comprises the following steps:

[0030] Step 1. Wastewater collection: Collect rainwater from the concrete mixing plant, wastewater from site washing, wastewater from sand separators, wastewater from spraying facilities, and domestic water through water pipes arranged on the ground of the site;

[0031] Step two, five-stage sedimentation: the collected wastewater is passed into the first-stage sedimentation tank for sedimentation, and then the wastewater impurities are precipitated in sequence through the second sedimentation tank, the third sedimentation tank, the fourth sedimentation tank and the fifth sedimentation tank, and finally Discharged into the cesspool for storage as sewage;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com