Contact plug, semiconductor device and method of manufacturing the same

A contact plug and manufacturing method technology, which is applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device parts, etc. The effect of reducing contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] A method of manufacturing a contact plug, comprising the steps of:

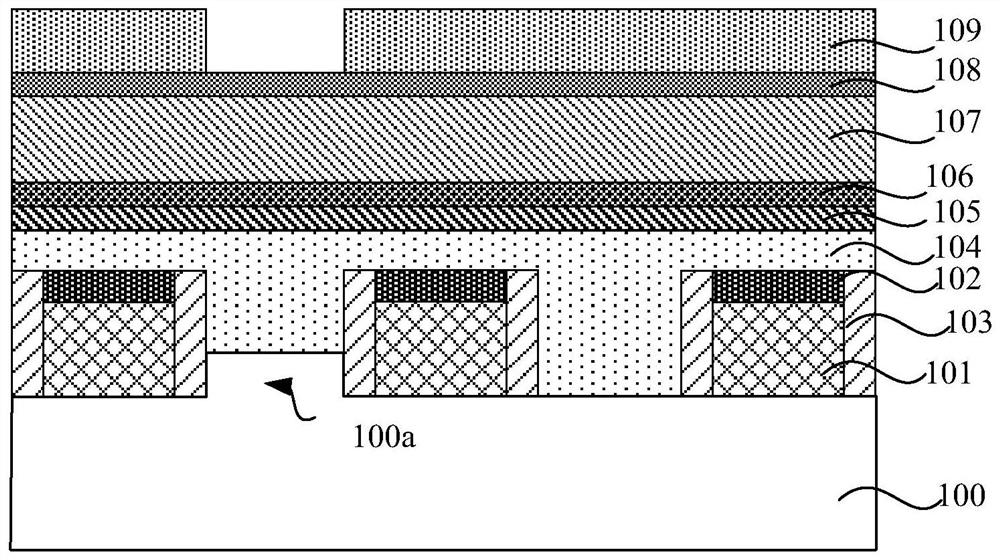

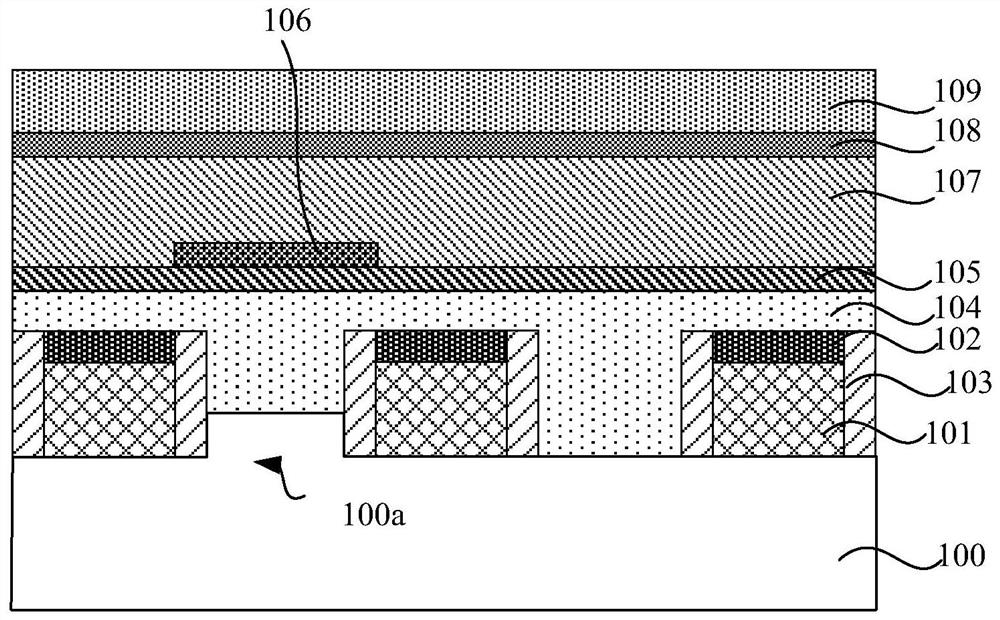

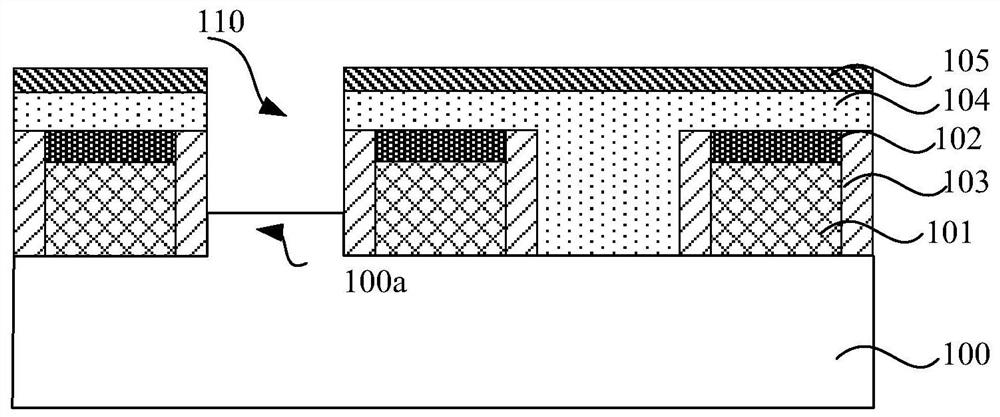

[0046] First, please refer to Figure 1A , 1B and Figure 2A , provide a semiconductor substrate 100, a gate structure 101 (which may be a polysilicon gate structure or a high-K metal gate structure) is formed on the semiconductor substrate 100, and the top of the gate structure 101 is covered with A silicon nitride mask layer 102, sidewalls 103 are formed on the sidewalls of the gate structure 102 and the silicon nitride mask layer 102, and fins 100a are formed in the semiconductor substrate 100 (which may be formed by embedded source-drain epitaxy source or drain region formed by the process);

[0047] Then, please continue to refer to Figure 1A , 1B and Figure 2A , depositing a sufficiently thick interlayer dielectric layer 104 on the surfaces of the semiconductor substrate 100, sidewalls 103, and silicon nitride mask layer 102, and planarizing the top of the interlayer dielectric layer 104;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com