Water-soluble graphene conductive ink and preparation method thereof

A conductive ink, water-soluble technology, applied in the field of water-soluble graphene conductive ink and its preparation, can solve the problems of restricting the use of water, restricting the application of organic solvents, etc., to achieve the effects of protecting the environment, ensuring personal health, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

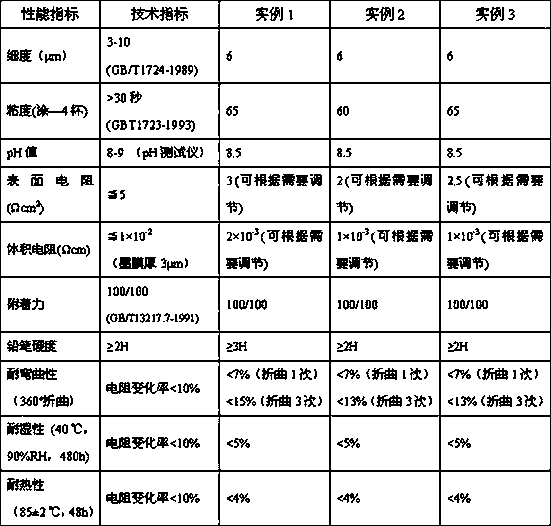

example 1

[0025] Example 1. Get 45 parts of water-soluble acrylic resin, 15 parts of water-soluble graphene powder, 35 parts of deionized water, 5 parts of auxiliary agents (1 part of colorant, 0.5 part of dispersant, 0.5 part of defoamer, 0.5 part of plasticizer , leveling agent 0.5 parts, epoxy silane coupling agent 2 parts), the above materials are calculated according to the mass percentage. Dissolve the water-soluble acrylic resin in deionized water to obtain a homogeneous aqueous solution. Add the water-soluble graphene powder under stirring and adding, and mix evenly. Then, the pre-dispersed material can be obtained by gradually adding additives under the condition of stirring; the stirring speed is 1000 rpm. The stirred slurry was then allowed to stand for 20 minutes and excess water was filtered through a filter press. Finally, the obtained mixed slurry is ground until the fineness of the material reaches below 10 microns; the ground material is filtered to obtain the water-s...

example 2

[0026] Example 2. Get 45 parts of water-soluble polyurethane fat, 15 parts of water-soluble graphene powder, 35 parts of deionized water, 5 parts of auxiliary agents (1 part of colorant, 0.5 part of dispersant, 0.5 part of defoamer, 0.5 part of plasticizer , leveling agent 0.5 parts, epoxy silane coupling agent 2 parts), the above materials are calculated according to the mass percentage. Dissolve water-soluble polyurethane into deionized water to obtain a homogeneous aqueous solution. Add the water-soluble graphene powder under stirring and adding, and mix evenly. Then, the pre-dispersed material can be obtained by gradually adding additives under the condition of stirring; the stirring speed is 1000 rpm. The stirred slurry was then allowed to stand for 20 minutes and excess water was filtered through a filter press. Finally, the obtained mixed slurry is ground until the fineness of the material reaches below 10 microns; the ground material is filtered to obtain the water-s...

example 3

[0027] Example 3. Get 25 parts of water-soluble polyurethane, 20 parts of water-soluble acrylic resin, 15 parts of water-soluble graphene powder, 35 parts of deionized water, 5 parts of auxiliary agents (1 part of colorant, 0.5 part of dispersant, 0.5 part of defoamer, 0.5 parts of plasticizer, 0.5 parts of leveling agent, 2 parts of epoxy silane coupling agent), the above materials are calculated according to the mass percentage. The water-soluble acrylic resin and the water-soluble polyurethane are respectively dissolved in deionized water to obtain a uniform aqueous solution, and then the two solutions are uniformly mixed under stirring conditions to obtain a uniform mixed solution. Next, add the water-soluble graphene powder under stirring and adding, and mix evenly. Then, the pre-dispersed material can be obtained by gradually adding additives under the condition of stirring; the stirring speed is 1000 rpm. The stirred slurry was then allowed to stand for 20 minutes and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com