Method for tabletting metoprolol succinate pellets

A technology of torolol pellets and succinic acid, which is applied in the directions of pill delivery, pharmaceutical formulations, microcapsules, etc., can solve the problems of increasing processes and costs, and achieves the advantages of reducing production links, small bulk density, and reducing stratification. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

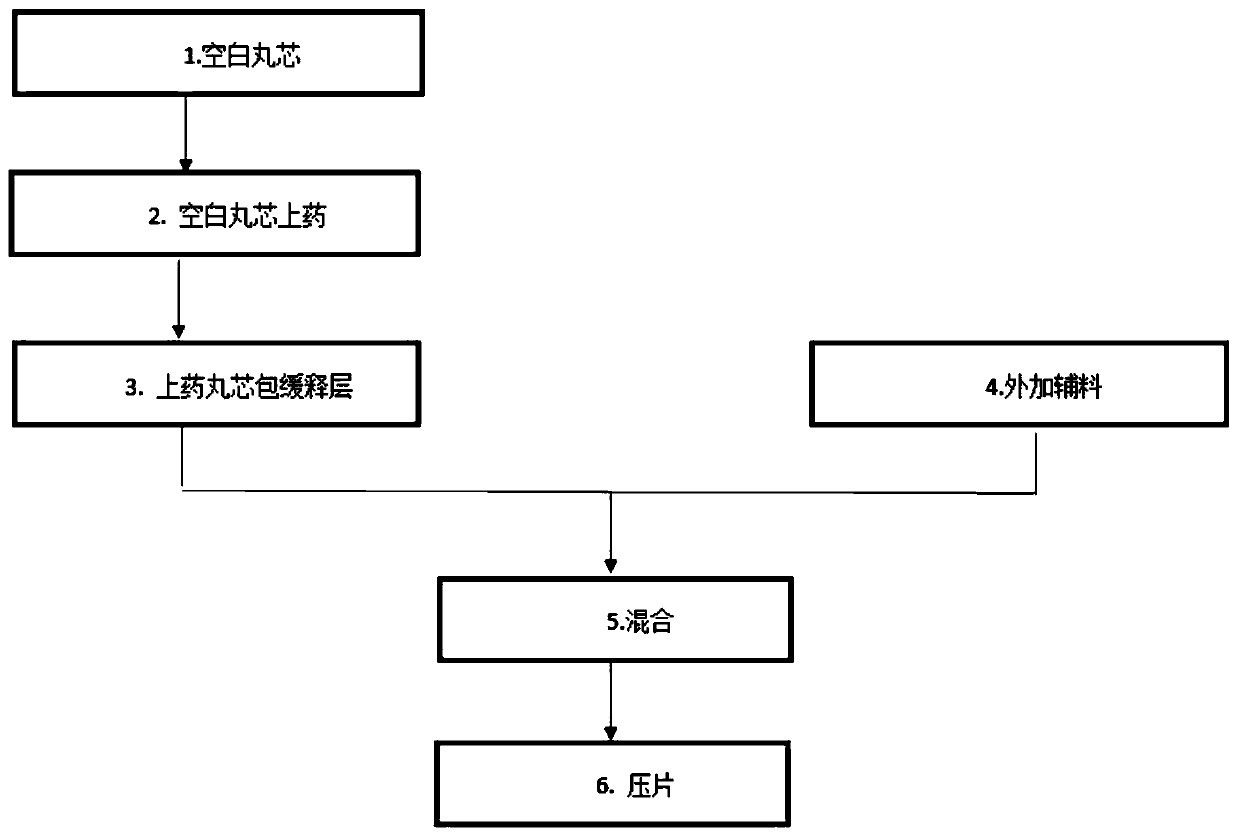

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Preparation of blank pellet core

[0029] Table 1 Blank pellet core A prescription composition:

[0030] composition proportion% Microcrystalline cellulose30% Silica70% Hypromellose10%

[0031] Preparation steps of blank pellet core:

[0032] (1) Ingredients and mixing: Weigh microcrystalline cellulose and silicon dioxide according to the prescription ratio and mix them evenly;

[0033] (2) Binder configuration: Weigh hypromellose according to the prescription ratio, mix it to 5% concentration, and stir evenly;

[0034] (3) Preparation: Place the uniformly mixed blank pellets in the centrifugal granulator, turn on the equipment, adjust the rotation speed of the main machine to 100-300r / min for the adhesive obtained in step 2, and combine the configured adhesive with The solvent is mixed and added to the storage tank, the rotating spraying speed is: 5-20r / min, and the spray gun pressure should be 0.5-1.5MPa;

Embodiment 2

[0035] Example 2: Preparation of blank pellet core

[0036] Table 2 Blank pellet core B prescription composition:

[0037] composition% Microcrystalline cellulose70% Silica30% Hypromellose10%

[0038] (1) Ingredients and mixing: Weigh the microcrystalline cellulose and silicon dioxide according to the prescription ratio and mix them evenly;

[0039] (2) Binder configuration: Weigh hypromellose according to the prescription ratio, mix it to 5% concentration, and stir evenly;

[0040] (3) Preparation: Place the uniformly mixed blank pellets in the centrifugal granulator, turn on the equipment, adjust the rotation speed of the main machine to 100-300r / min for the adhesive obtained in step 2, and combine the configured adhesive with The solvent is mixed and added to the storage tank, the rotating spraying speed is: 5-20r / min, and the spray gun pressure should be 0.5-1.5MPa;

Embodiment 3

[0041] Example 3: Preparation of blank pellet core C

[0042] Table 3 Blank pellet core C prescription composition:

[0043] composition% Microcrystalline cellulose10% Silica90% Hypromellose10%

[0044] (1) Ingredients and mixing: Weigh the microcrystalline cellulose and silicon dioxide according to the prescription ratio and mix them evenly;

[0045] (2) Binder configuration: Weigh hypromellose according to the prescription ratio, mix it to 5% concentration, and stir evenly;

[0046] (3) Preparation: Place the uniformly mixed blank pellets in the centrifugal granulator, turn on the equipment, adjust the rotation speed of the main machine to 100-300r / min for the adhesive obtained in step 2, and combine the configured adhesive with The solvent is mixed and added to the storage tank, the rotating spraying speed is: 5-20r / min, and the spray gun pressure should be 0.5-1.5MPa;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com