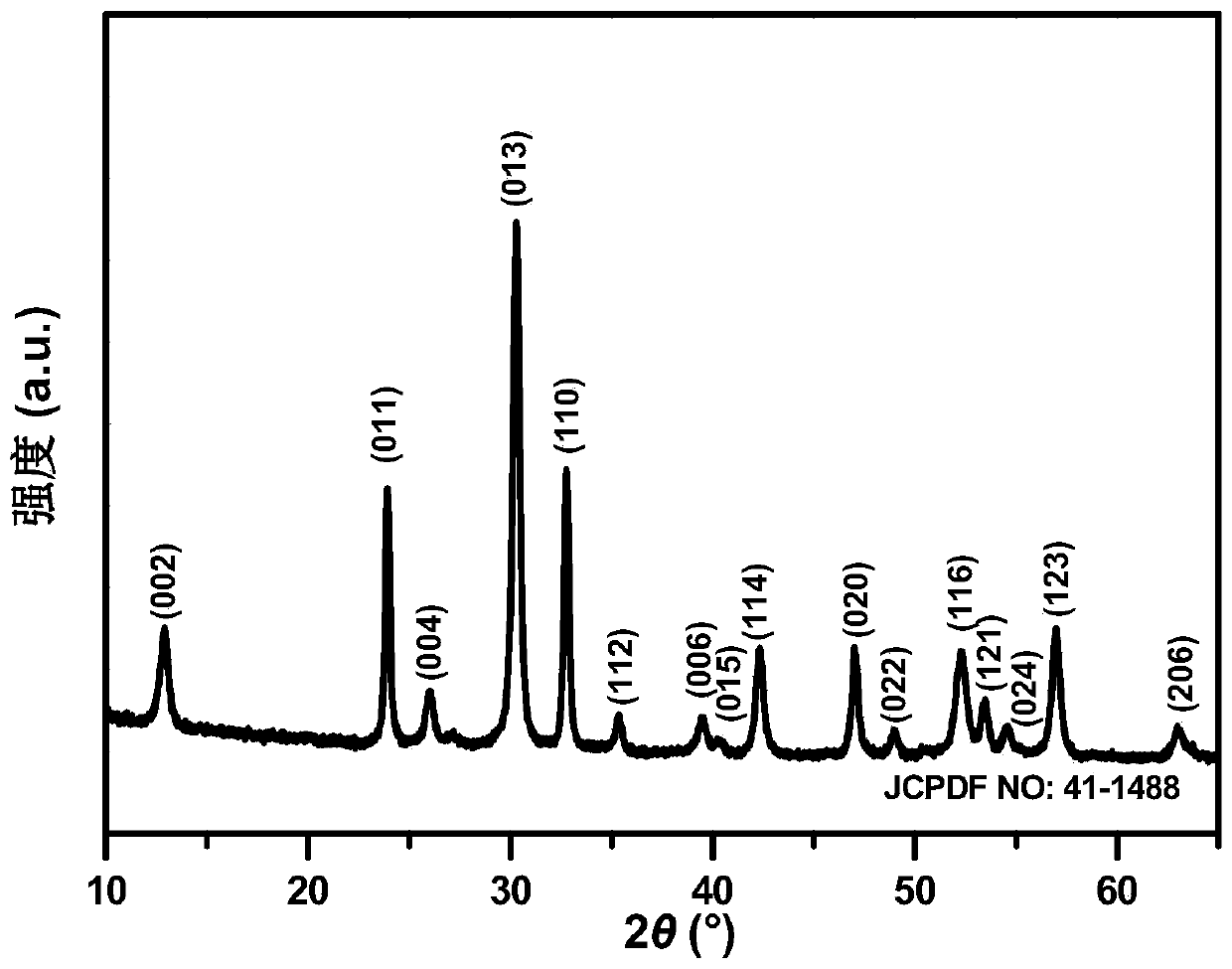

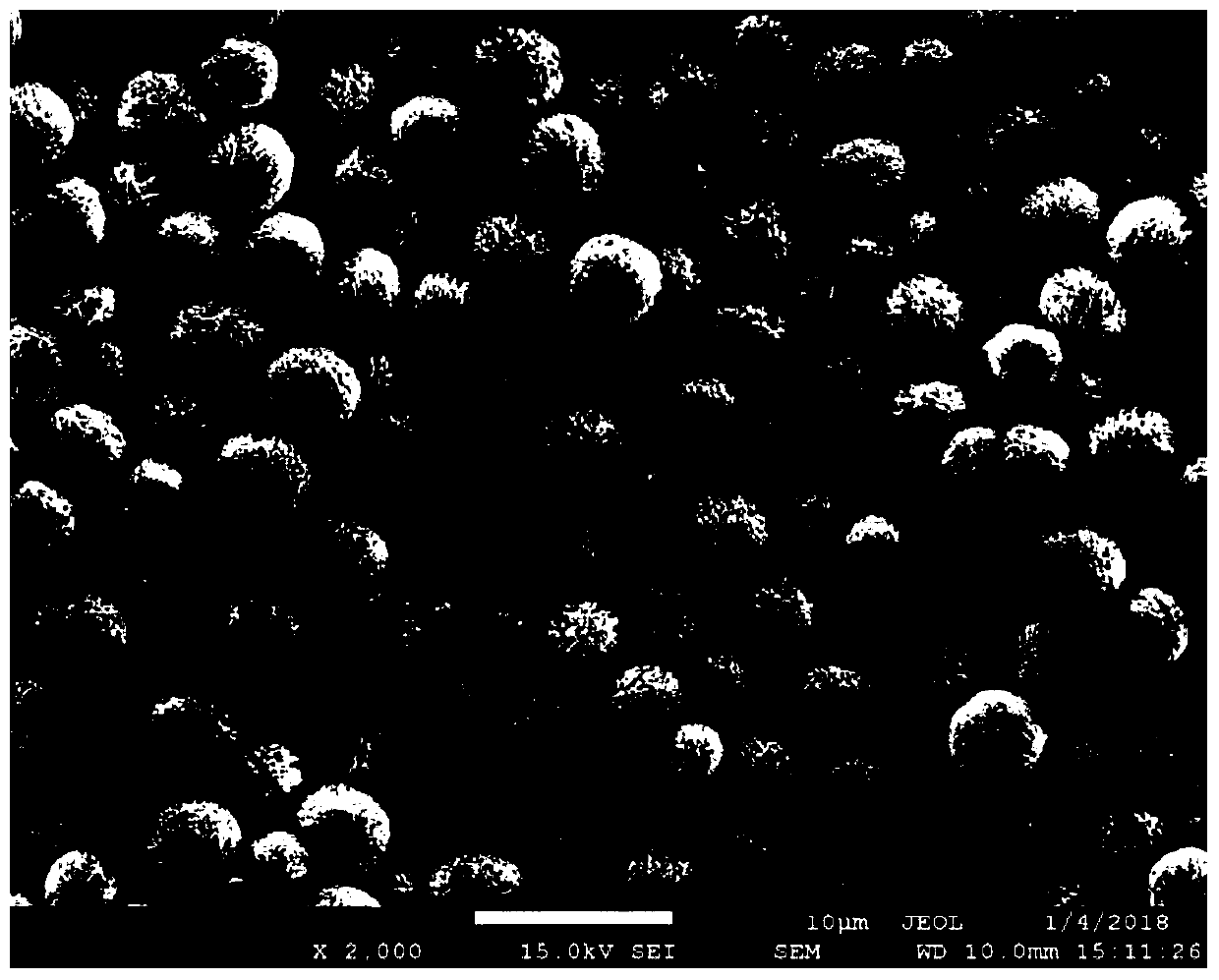

Preparation method of bismuthyl carbonate

A bismuth oxycarbonate and bismuth nitrate technology, which is applied in chemical instruments and methods, bismuth compounds, physical/chemical process catalysts, etc., can solve problems such as large size of bismuth oxycarbonate microspheres, less environmentally friendly environmental applications, and long reaction time , to achieve the effect of uniform shape, easy mass production and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of preparation method of bismuth oxycarbonate as the embodiment of the present invention, described method comprises the following steps:

[0034] (1) 7.5 mmol of bismuth nitrate pentahydrate was dissolved in 25 mL of 1 mol / L dilute nitric acid, ultrasonically treated for 5 minutes and magnetically stirred for 10 minutes to obtain solution A;

[0035] (2) Add 5 mmol citric acid to solution A, and stir magnetically for 10 minutes until clear solution B is obtained;

[0036] (3) dropwise adding 2mol / L sodium hydroxide solution to the solution B to adjust the pH of the solution B to be 7.5, to obtain the mixed system C;

[0037] (4) Put the mixed system C in the reaction kettle to carry out the hydrothermal synthesis reaction at 180°C for 12 hours;

[0038] (5) naturally cool to room temperature, centrifuge the product obtained in step (4) and collect the solid, wash the solid with water for 3 times and wash with alcohol for 3 times, then dry it in a vacuum oven at...

Embodiment 2

[0049] As a method for degrading organic dyes in water according to an embodiment of the present invention, the method comprises the following steps:

[0050] (1) 25mg of bismuth oxycarbonate prepared in Example 1 was added to 50mL of 20mg / L methyl orange solution, dispersed evenly, mixture system A;

[0051] (2) The mixture system A was kept stirring for 60 minutes in the dark;

[0052] (3) Use a 500W mercury lamp to irradiate the mixture system A, and take samples at set intervals, then immediately separate the solid and liquid and record the reaction time.

[0053]The concentration of methyl orange in the sample was measured at 463 nm with a Shimadzu-2500 ultraviolet-visible spectrophotometer, and it was found that the degradation efficiency was 99.2% in 90 minutes.

Embodiment 3

[0055] As a method for degrading organic dyes in water according to the embodiment of the present invention, the only difference between this embodiment and embodiment 2 is: adding 25 mg of bismuth oxycarbonate prepared in embodiment 1 to 50 mL of 20 mg / L rhodamine B solution middle.

[0056] The rhodamine B concentration in the sample was measured at 554 nm with a Shimadzu-2500 ultraviolet-visible spectrophotometer, and it was found that the degradation efficiency was 99.9% in 20 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com