An integrated treatment process for river and lake sludge dehydration and consolidation

A treatment process and sludge technology, which is applied in the field of river and lake sludge dehydration and consolidation integrated treatment process, can solve the problems of low treatment efficiency of the dehydration system and rough process design, and achieve good environmental and social benefits, good dehydration effect, and faster The effect of drug dose reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

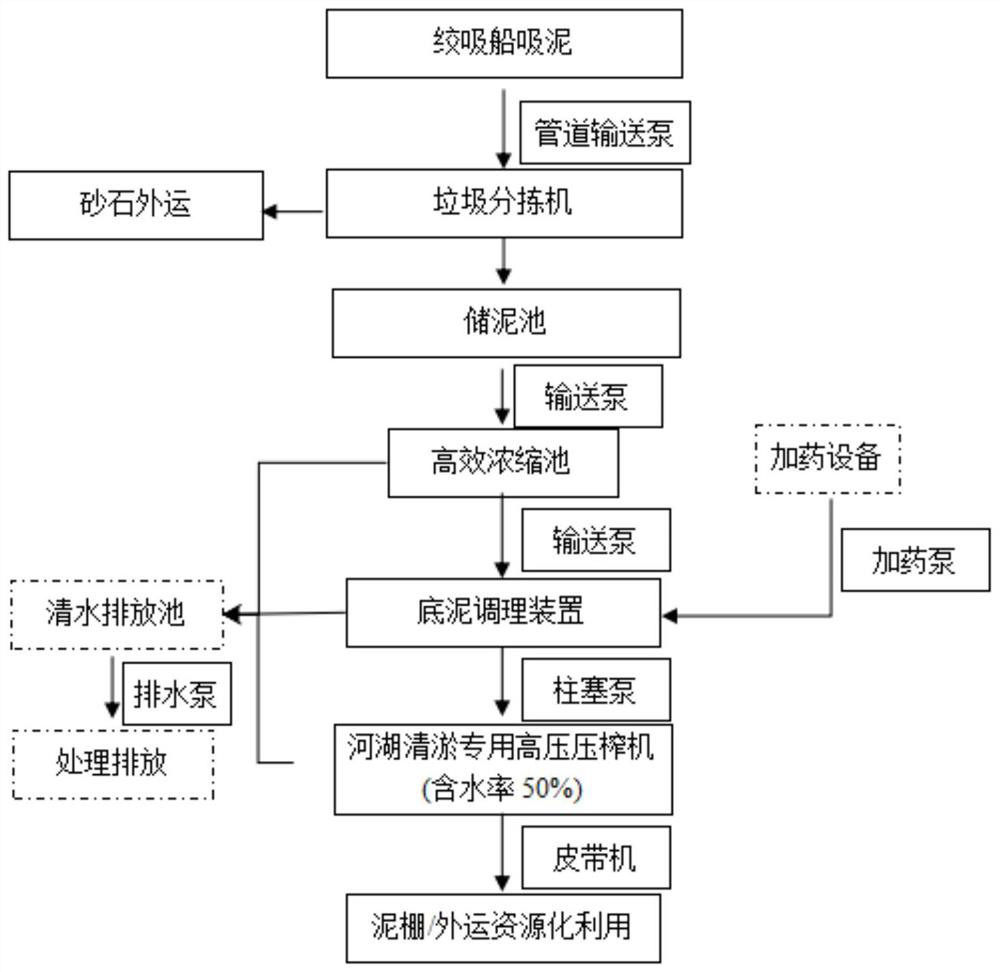

Embodiment 1

[0027] After the dredged silt of a river in the suburbs of Shanghai is transferred to the bank, the river and lake sludge dewatering and consolidation integration process of the present invention is used for dehydration and consolidation treatment; the river and lake sludge dehydration and consolidation integration device is used for treatment, and the The river and lake sludge dewatering and consolidation integrated device includes: cutter suction ship, pipeline conveying pump, garbage sorting machine, mud storage tank, transfer pump, high-efficiency concentration tank, conveying pump, sediment conditioning device, dosing equipment, dosing Pumps, plunger pumps, high-pressure presses for river and lake dredging, belt conveyors, clean water discharge tanks, drainage pumps; the inlet of the pipeline conveying pump is connected to the mud conveying pipeline of the cutter suction ship, and the outlet is connected to the inlet of the garbage sorter; mud storage The inlet of the tank...

Embodiment 2

[0037] After the silt after dredging in a certain river channel in the central urban area of Jiangsu is transferred to the shore, the dewatering and consolidation process is carried out by adopting the river and lake sludge dehydration and consolidation integration process of the present invention; the river and lake sludge dehydration and consolidation integration device is used for treatment, and the The river and lake sludge dehydration and consolidation integrated device includes: cutter suction ship, pipeline conveying pump, garbage sorting machine, mud storage tank, transfer pump, high-efficiency concentration tank, conveying pump, sediment conditioning device, dosing equipment, Drug pumps, plunger pumps, high-pressure presses for river and lake dredging, belt conveyors, clear water discharge tanks, drainage pumps; the inlet of the pipeline conveying pump is connected to the mud conveying pipeline of the cutter suction ship, and the outlet is connected to the inlet of th...

Embodiment 3

[0047] After the dredged silt of a river in the suburbs of Shanghai is transferred to the bank, the river and lake sludge dewatering and consolidation integration process of the present invention is used for dehydration and consolidation treatment; the river and lake sludge dehydration and consolidation integration device is used for treatment, and the The river and lake sludge dewatering and consolidation integrated device includes: cutter suction ship, pipeline conveying pump, garbage sorting machine, mud storage tank, transfer pump, high-efficiency concentration tank, conveying pump, sediment conditioning device, dosing equipment, dosing Pumps, plunger pumps, high-pressure presses for river and lake dredging, belt conveyors, clean water discharge tanks, drainage pumps; the inlet of the pipeline conveying pump is connected to the mud conveying pipeline of the cutter suction ship, and the outlet is connected to the inlet of the garbage sorter; mud storage The inlet of the tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com