Acid rain-resistant freezing-resistant repairing material for rail transit engineering concrete structure

A rail transit engineering and concrete structure technology, applied in the field of building materials, to achieve the effects of good crack resistance, good integrity, and good acid corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

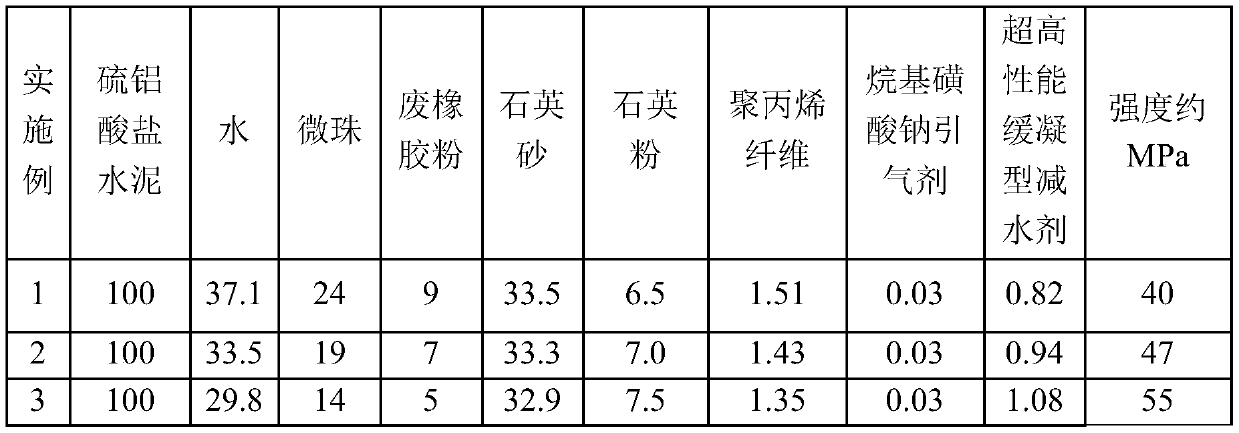

[0031] Example 1: The strength of the structural concrete to be repaired is in the range of 35MPa to 40MPa, and the repairing material with a ratio of 1 is used;

Embodiment 2

[0032] Example 2: The strength of the structural concrete to be repaired is in the range of 42MPa to 47MPa, and the repair material with a ratio of 2 is used;

Embodiment 3

[0033] Example 3: The concrete strength of the structure to be repaired is in the range of 50 MPa to 55 MPa, and the repairing material with a ratio of 3 is used.

[0034] The preparation process is:

[0035] According to Table 1, mix 42.5 strength grade sulfoaluminate cement, microbeads, waste rubber powder, quartz sand, and quartz powder evenly, then add water, ultra-high performance retarding water reducer, sodium alkylsulfonate primer Air agent (ultra-high-performance retarding type water reducer, sodium alkylsulfonate air-entraining agent and water are added together), stir evenly, and finally sprinkle polypropylene fiber into the stirred slurry, stir until the fiber is uniform There is no agglomeration phenomenon in the dispersion in the slurry. Wet spray machine sprays. The thickness of each layer of spraying is generally 10mm to 15mm. According to the degree of damage, the spraying is repaired. After spraying each layer for 2 hours, spray the second layer.

[0036] Ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com