Flame-retardant additive, preparation method therefor and application of flame-retardant additive

A flame retardant additive and reaction technology, applied in the field of flame retardant additives and their preparation, can solve the problems of high manufacturing and use costs, and achieve the effects of reducing production costs, increasing profit margins, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

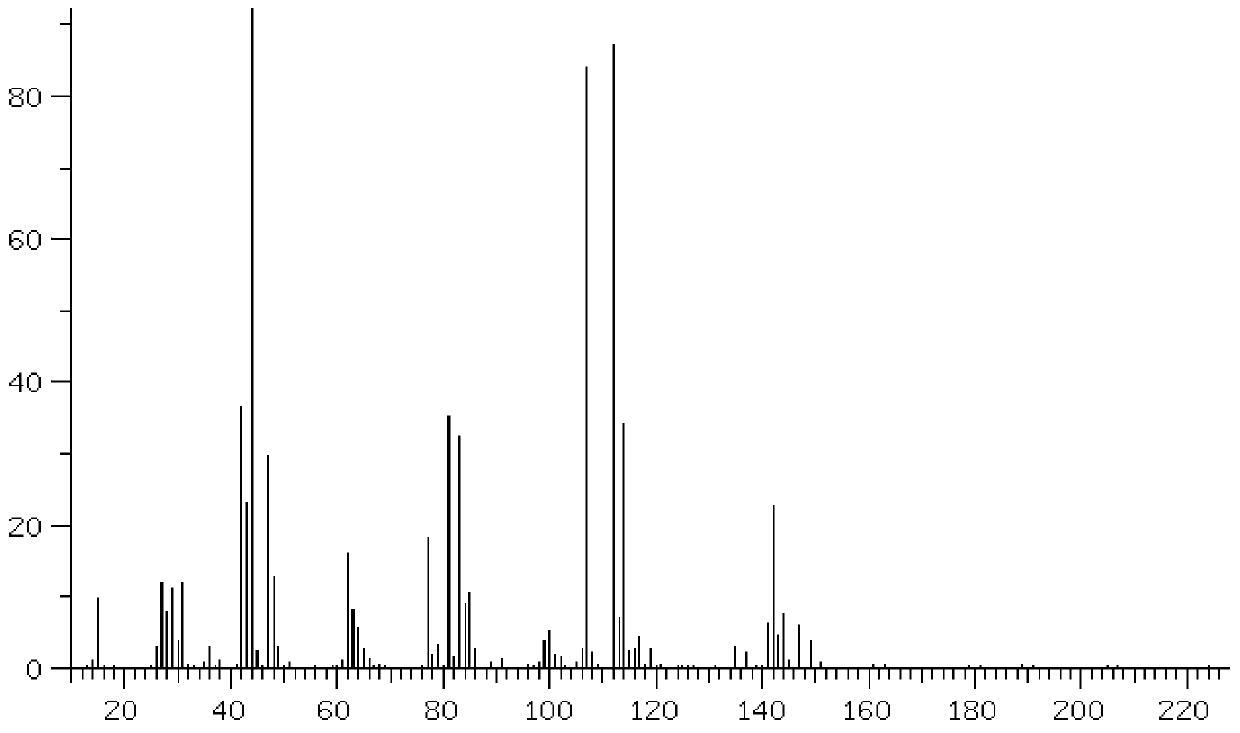

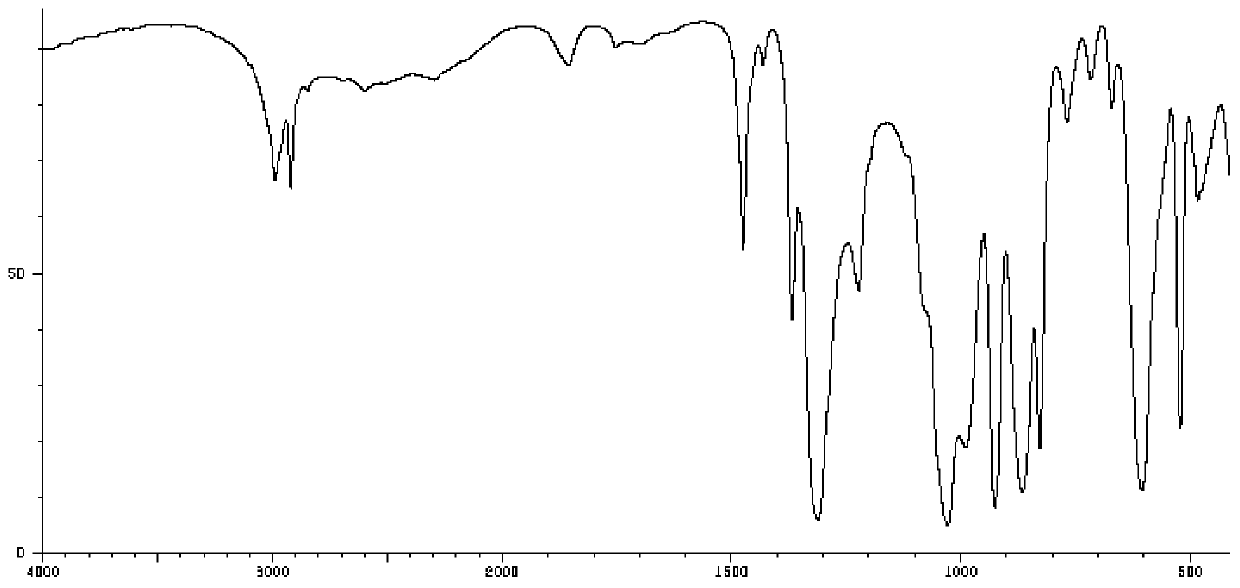

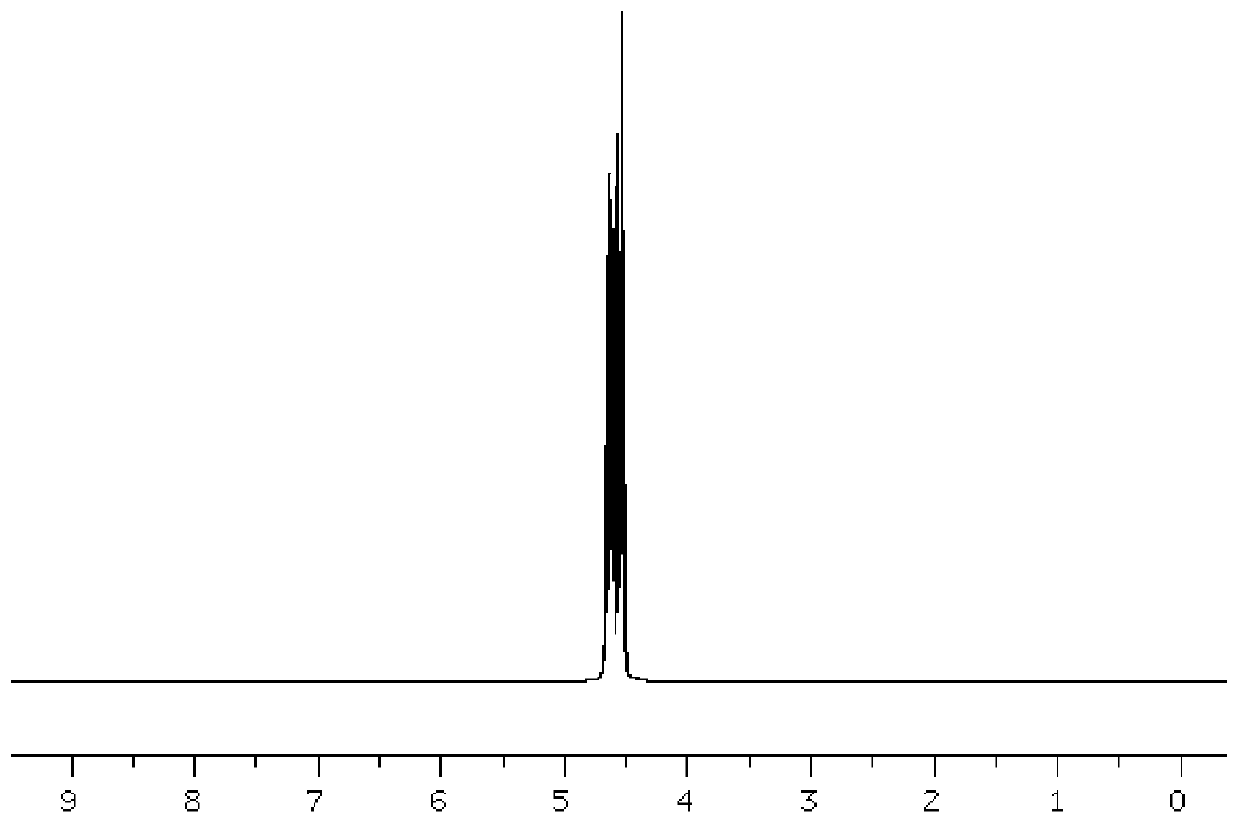

Image

Examples

preparation example Construction

[0053] Preparation of reaction intermediate B:

[0054] S01: At room temperature, add 310g of ethylene glycol (reactant A) and 350g of anhydrous dichloromethane (non-aqueous solvent) into a three-necked flask with a capacity of 2000mL, cool down to 0°C, and continue stirring for 0.5h until the solution becomes Colorless and transparent, the three-necked bottle is connected to an external gas absorption device.

[0055] In the S01 step, the non-aqueous solvent is added to make the reactants more uniformly dispersed and provide a stable reaction environment. The non-aqueous solvent treatment in this step uses dichloromethane, can also select acetonitrile, tetrahydrofuran, chloroform, ethyl acetate, dimethyl carbonate, diethyl carbonate, ethyl methyl carbonate, n-hexane, cyclohexane, One or more mixtures of organic solvents such as benzene and toluene, which have good dispersibility and have no influence on the reaction process. The added quality of the non-aqueous solvent can ...

Embodiment 1

[0064] Preparation of compound 1 (vinyl phenol phosphate or 2-phenol-2-oxo-1,3,2-dioxaphospholane):

[0065] Add 200g of dichloromethane (solvent, the same effect as the aforementioned non-aqueous solvent, optional use) and 100g of phenol (reactant C) into a 500mL three-necked flask at room temperature, and stir at room temperature for 0.5h to completely dissolve the phenol, and the solution is free. The color is transparent, the three-necked bottle is connected to an external gas absorption device, and then 143g of reaction intermediate B is slowly added to a 500mL three-necked bottle through a dropping funnel, the dropping rate is controlled at 1 drop / second, and the reaction temperature is 0°C. The dropwise addition of body B releases a large amount of heat and a large amount of HCl gas. After all the drops are completed, the solution is colorless and transparent (1.5h after dropping in the reaction intermediate B), and then the temperature is raised to room temperature and ...

Embodiment 2

[0071] Preparation of Compound 2 (4-methylphenol-based vinyl phosphate or 2-(4-methylphenol-based)-2-oxo-1,3,2-dioxaphospholane):

[0072] Add 200g of dichloromethane and 120g of 4-methylphenol (reactant C) into a 500ml three-necked flask at room temperature, stir at room temperature for 0.5h, 4-methylphenol is completely dissolved, and the solution is colorless and transparent, and the three-necked flask is connected to an external gas absorption device, then slowly add 143g of reaction intermediate B into a 500ml three-necked flask via a dropping funnel, control the dropping rate to 1 drop / second, and the reaction temperature is 0°C. With the dropwise addition of reaction intermediate B, a large amount of Heat and a large amount of HCl gas is released, and the solution is colorless and transparent after dripping. Continue to stir at room temperature for 12 hours, then remove dichloromethane to obtain a light yellow solid, which is crystallized by n-hexane and dried in vacuo f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com