A kind of kelp cellulose nanofiber and preparation method thereof

A nanofiber and cellulose technology, applied in nanotechnology and other directions, can solve problems such as unfriendly, corrosive environment of reagents, etc., and achieve the effect of simple production process and increased charge density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

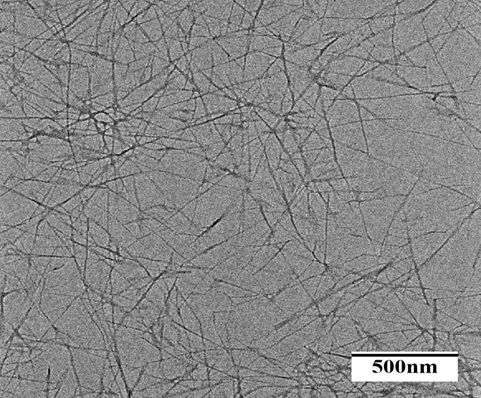

Image

Examples

Embodiment 1

[0026] (1) Weigh 0.5g of kelp cellulose CNC in 500mL of ultrapure water, stir magnetically at room temperature for 30min to fully swell;

[0027] (2) The swollen CNF in step (1) is placed in an ultrasonic cell disrupter for 10 minutes and the power is 150W to fully disperse the CNC;

[0028] (3) Add 0.008g TEMPO, 0.05gNaBr, 2.87gNaClO in step (2) under the condition of ice bath (0-5℃);

[0029] (4) Adjust the pH of the solution in step (3) with 0.1mol / L NaOH and 0.1mol / L HCl, so that the pH value is controlled at about 10;

[0030] (5) Until the pH value of the solution does not change in step (4), adjust the pH value of the solution to 7, and add 3ml of absolute ethanol to terminate the reaction;

[0031] (6) The CNF suspension obtained in step (5) was heated at 5000 g Centrifuge 3 times under certain conditions, and wash the supernatant 3 times in a Buchner funnel;

[0032] (7) The CNF suspension obtained in step (6) was placed in an ultrasonic cell disruptor for 5 min an...

Embodiment 2

[0035] (1) Weigh 0.5g of kelp cellulose CNC in 500mL of ultrapure water, stir magnetically at room temperature for 30min to fully swell;

[0036] (2) The swollen CNF in step (1) is placed in an ultrasonic cell disruptor for 10 minutes and the power is 150W to fully disperse the CNF;

[0037] (3) Add 0.008g TEMPO, 0.05gNaBr, 3.6gNaClO in step (2) under the condition of ice bath (0-5℃);

[0038] (4) Adjust the pH of the solution in step (3) with 0.1mol / L NaOH and 0.1mol / L HCl, so that the pH value is controlled at about 10;

[0039] (5) Until the pH value of the solution does not change in step (4), adjust the pH value of the solution to 7, and add 3ml of absolute ethanol to terminate the reaction;

[0040] (6) The CNF suspension obtained in step (5) was heated at 5000 g Centrifuge 3 times under certain conditions, and wash the supernatant 3 times in a Buchner funnel;

[0041] (7) The CNF suspension obtained in step (6) was placed in an ultrasonic cell disruptor and sonicated...

Embodiment 3

[0044] (1) Weigh 0.5g of kelp cellulose CNC in 500mL of ultrapure water, stir magnetically at room temperature for 30min to fully swell;

[0045] (2) The swollen CNF in step (1) is placed in an ultrasonic cell disruptor for 10 minutes and the power is 150W to fully disperse the CNF;

[0046](3) Add 0.008g TEMPO, 0.05gNaBr, 4.32gNaClO in step (2) under ice bath (0-5°C);

[0047] (4) Adjust the pH of the solution in step (3) with 0.1mol / L NaOH and 0.1mol / L HCl, so that the pH value is controlled at about 10;

[0048] (5) Until the pH value of the solution does not change in step (4), adjust the pH value of the solution to 7, and add 3ml of absolute ethanol to terminate the reaction;

[0049] (6) The CNF suspension obtained in step (5) was heated at 5000 g Centrifuge 3 times under certain conditions, and wash the supernatant 3 times in a Buchner funnel;

[0050] (7) The CNF suspension obtained in step (6) was placed in an ultrasonic cell disruptor and sonicated for 5 minutes w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com