A kind of preparation method of special pressure-sensitive adhesive composition and adhesive tape

A technology of pressure-sensitive adhesives and compositions, applied in the direction of adhesives, adhesive types, pressure-sensitive films/sheets, etc., which can solve problems such as poor resistance to living agents, intolerance to living agents, and decreased bonding durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

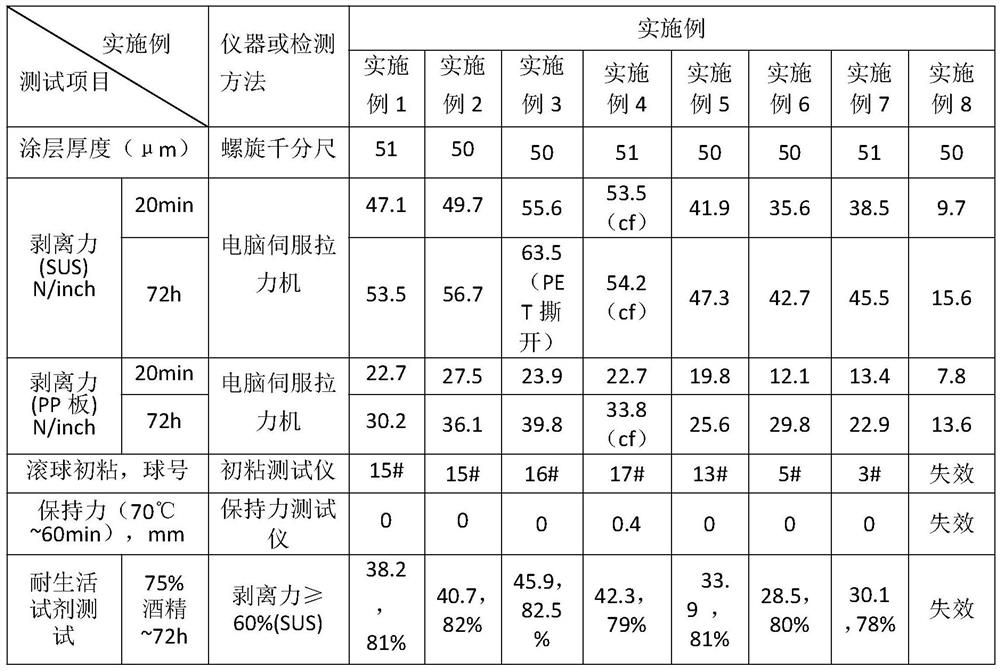

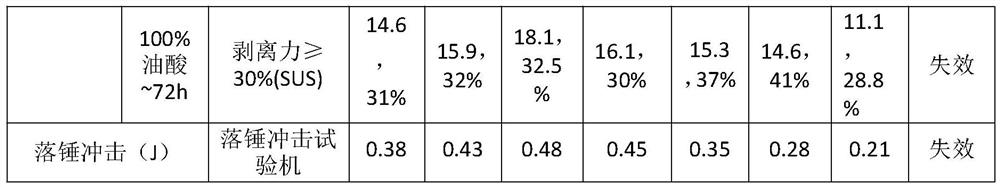

Examples

Embodiment 1

[0026] 1) Preparation of rubber modified adhesive: In a 1000ml four-necked reaction bottle, put in toluene 560 and start the stirring device at a speed of 150rpm, and put in nitrile rubber slices in turn while stirring 100g, heat up to about 45°C, introduce nitrogen at the same time, wait for 3 hours to be stirred until it is completely dissolved, put in 8g of lauryl acrylate, 3g of hydroxyethyl acrylate, and then heat up to 80°C, then add benzoyl peroxide solution ( Diluted to 10% concentration with toluene) 9g, maintain the reaction for 4h, then stop introducing nitrogen to end the reaction, then put in 1.5g of antioxidant 1010, 0.3g of light stabilizer UV-144, 50g of terpene phenolic resin TP2019, liquid butyronitrile Rubber LR820 5g, continue to stir until it dissolves, and discharge when the temperature drops below 45°C;

[0027]2) Coating process of special adhesive: coating the special adhesive on the release surface of PET release film, baking temperature is 110°C, ba...

Embodiment 2

[0029] 1) Preparation of rubber modified adhesive: In a 1000ml four-necked reaction bottle, put in toluene 560 and start the stirring device at a speed of 150rpm, and put in nitrile rubber slices in turn while stirring 100g, heat up to about 45°C, introduce nitrogen gas at the same time, wait for 3 hours to be stirred until it is completely dissolved, put in 15g of lauryl acrylate, 3g of hydroxyethyl acrylate, and then heat up to 80°C, then add benzoyl peroxide solution ( Diluted to 10% concentration with toluene) 9g, maintain the reaction for 4h, then stop introducing nitrogen to end the reaction, then put in 1.5g of antioxidant 1010, 0.3g of light stabilizer UV-144, 50g of terpene phenolic resin TP2019, liquid butyronitrile Rubber LR820 10g, continue to stir until it dissolves, and discharge when the temperature drops below 45°C;

[0030] 2) Coating process of special adhesive: coating the special adhesive on the release surface of PET release film, baking temperature is 11...

Embodiment 3

[0032] 1) Preparation of rubber modified adhesive: In a 1000ml four-necked reaction bottle, put in toluene 560 and start the stirring device at a speed of 150rpm, and put in nitrile rubber slices in turn while stirring 100g, heat up to about 45°C, introduce nitrogen gas at the same time, stir for 3 hours and after it is completely dissolved, put in 20g of lauryl acrylate and 3g of hydroxyethyl acrylate, then heat up to 80°C, add benzoyl peroxide solution ( Diluted to 10% concentration with toluene) 9g, maintain the reaction for 4h, then stop introducing nitrogen to end the reaction, then put in 1.5g of antioxidant 1010, 0.3g of light stabilizer UV-144, 50g of terpene phenolic resin TP2019, liquid butyronitrile Rubber LR820 15g, continue to stir until it dissolves, and discharge when the temperature drops below 45°C;

[0033] 2) Coating process of special adhesive: coating the special adhesive on the release surface of PET release film, baking temperature is 110°C, baking time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com