A kind of fuel oil desulfurizer and preparation method thereof

A desulfurizer and fuel oil technology, applied in the treatment of hydrocarbon oil, petroleum industry, refined hydrocarbon oil, etc., can solve the problems of difficult separation and recovery, low desulfurization rate, etc., achieve high catalytic oxidation efficiency, good selectivity, and promote oxidative desulfurization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

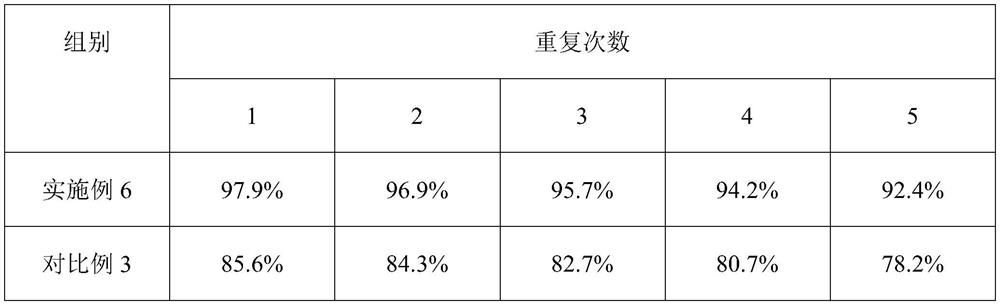

Examples

Embodiment 1

[0028] Preparation of Example 1 Porous Aluminum-based Metal Oxide

[0029] (1) The triblock copolymer Pluronic F127 (molecular formula is EO 106 PO 70 EO 106, EO is ethylene oxide, PO is propylene oxide; average molecular weight 12600) is dissolved in the mixed solvent (the volume ratio of absolute alcohol and glacial acetic acid is 5:2) that absolute ethanol and glacial acetic acid form, described The mixing ratio of Pluronic F127 and mixed solvent is 1g:25mL, stir and mix well to obtain mixed solution A;

[0030] (2) Add 100g of precursor mixture to 400g of the mixed solution A obtained in step (1), stir and dissolve to obtain mixed solution B, the precursor mixture is composed of 6.607g methyl orthosilicate, 65.129g aluminum nitrate nonahydrate , 28.264g mixed composition of cerium nitrate hexahydrate, the mixing ratio is based on SiO 2 :Al 2 o 3 :CeO 2 The molar ratio is calculated as 1:2:1.5.

[0031] (3) Immerse the three-dimensionally ordered polystyrene templat...

Embodiment 2

[0032] Preparation of Example 2 Porous Aluminum-based Metal Oxide

[0033] (1) The triblock copolymer Pluronic F127 (molecular formula is EO 106 PO 70 EO 106 , EO is ethylene oxide, PO is propylene oxide; average molecular weight 12600) is dissolved in the mixed solvent (the volume ratio of absolute alcohol and glacial acetic acid is 5:1.5) that absolute ethanol and glacial acetic acid form, described The mixing ratio of Pluronic F127 and mixed solvent is 1g:20mL, stir and mix well to obtain mixed solution A;

[0034] (2) Add 100g of precursor mixture to 400g of the mixed solution A obtained in step (1), stir and dissolve to obtain mixed solution B, the precursor mixture consists of 4.653g methyl orthosilicate, 68.805g aluminum nitrate nonahydrate , 26.542g mixed composition of cerium nitrate hexahydrate, the mixing ratio is based on SiO 2 :Al 2 o 3 :CeO 2 The molar ratio is calculated as 1:3:2.

[0035] (3) Immerse the three-dimensionally ordered polystyrene template ...

Embodiment 3

[0036] Preparation of Example 3 Porous Aluminum-based Metal Oxide

[0037] (1) The triblock copolymer Pluronic F127 (molecular formula is EO 106 PO 70 EO 106 , EO is ethylene oxide, PO is propylene oxide; average molecular weight 12600) is dissolved in the mixed solvent (the volume ratio of absolute alcohol and glacial acetic acid is 5:2.5) that absolute ethanol and glacial acetic acid form, described The mixing ratio of Pluronic F127 and mixed solvent is 1g:30mL, stir and mix to obtain mixed solution A;

[0038] (2) Add 100g of precursor mixture to 350g of mixed solution A obtained in step (1), stir and dissolve to obtain mixed solution B, the precursor mixture is composed of 2.757g methyl orthosilicate, 81.520g aluminum nitrate nonahydrate , 15.723g mixed composition of cerium nitrate hexahydrate, the mixing ratio is based on SiO 2 :Al 2 o 3 :CeO 2 The molar ratio is calculated as 0.5:3:1.

[0039] (3) Immerse the three-dimensionally ordered polystyrene template with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com