High throughput preparation method of sliding electric contact material composed of ingredients in gradient distribution

A sliding electrical contact and composition gradient technology, which is applied in the fields of sliding electrical contact materials and high-throughput preparation, can solve problems such as huge workload, and achieve the effects of reducing the amount of experiments, simple operation, and strong operability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: silver graphene composite sliding electrical contact material

[0036] 1) Taking silver and graphene with a purity of 99.99% as raw materials, weighing and configuring 16 raw materials with different composition ratios, the composition ratios are shown in Table 1, and the weight of each composition composite powder is 300g.

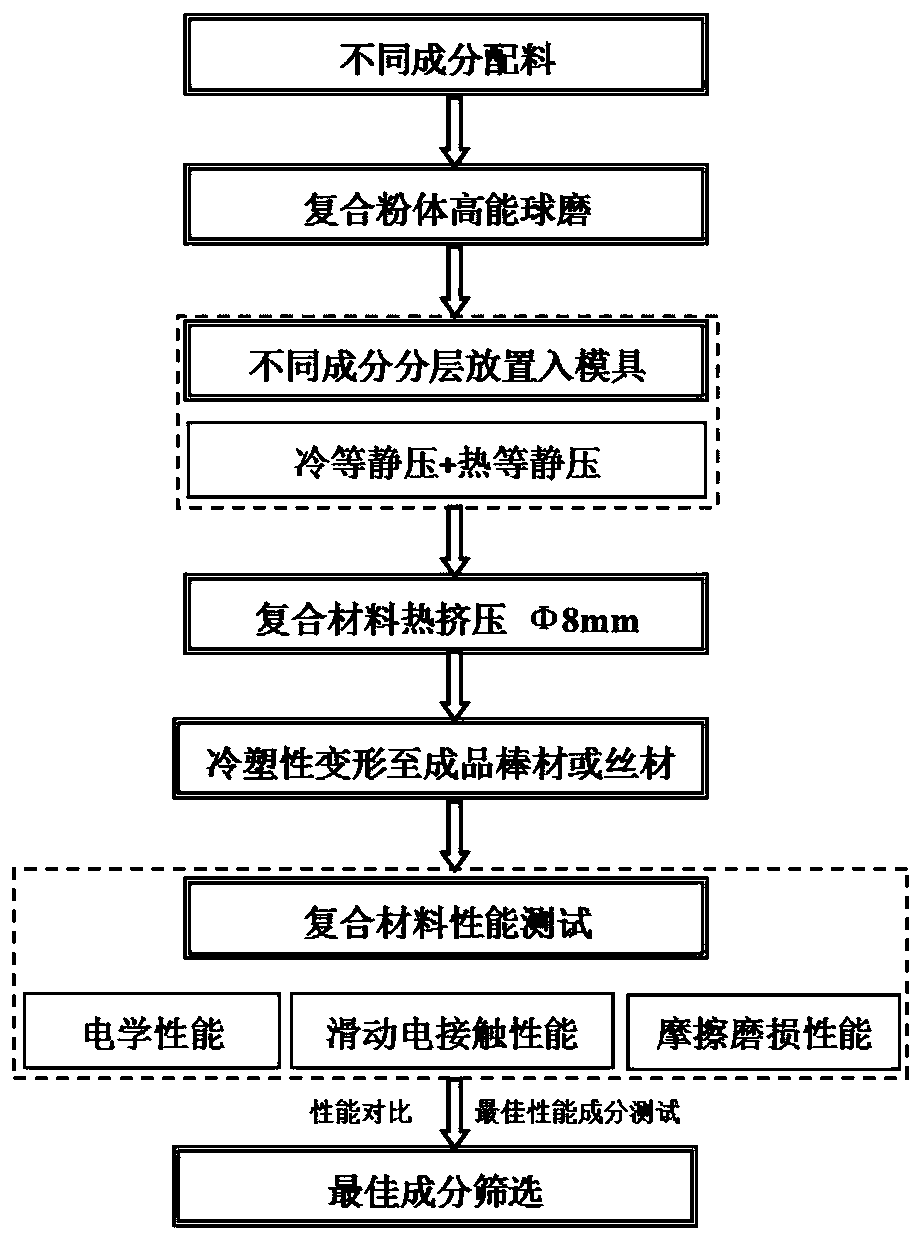

[0037]2) Mix the powders of the above 16 components by ball milling with a high-throughput desktop planetary ball mill to make composite powders;

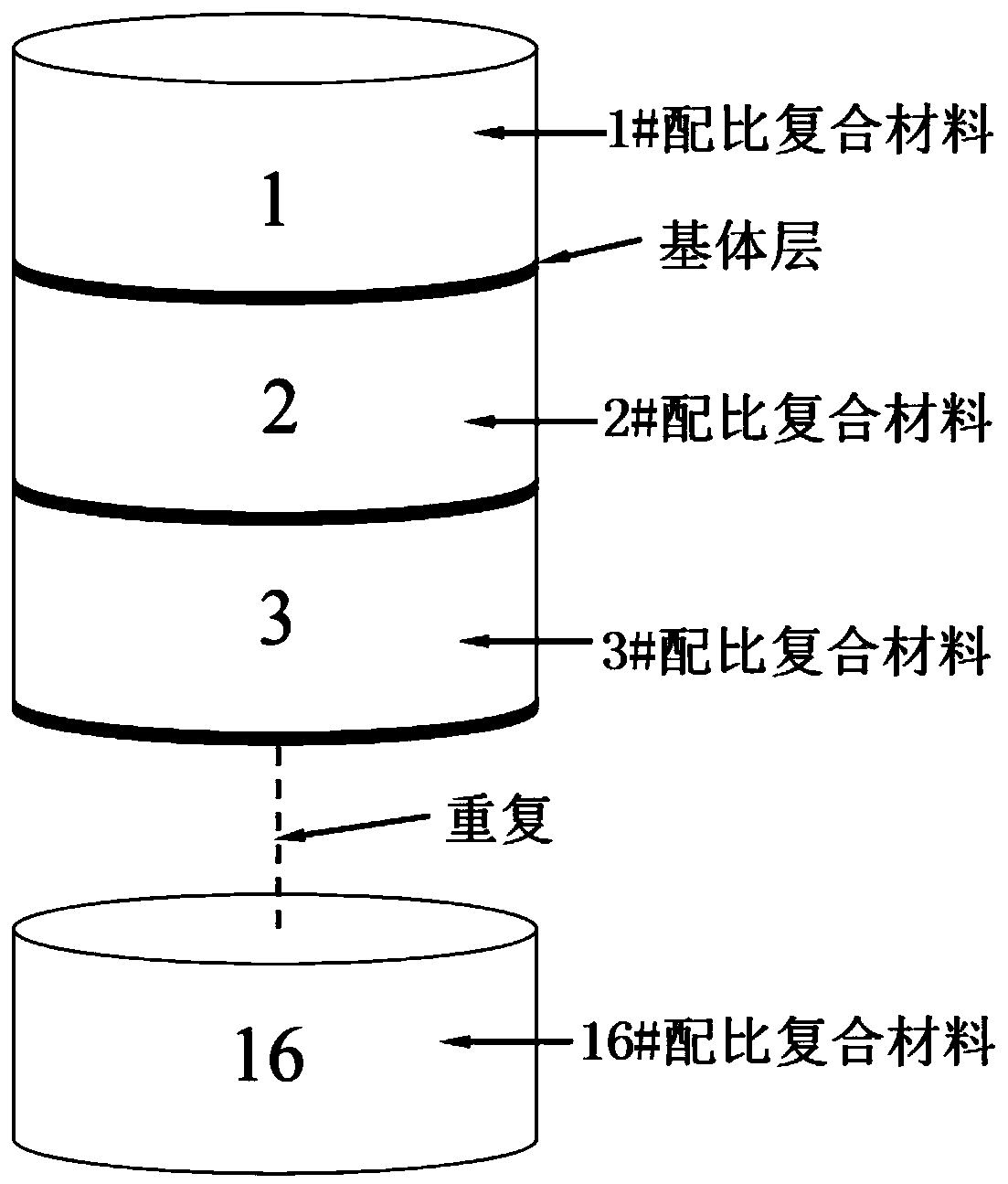

[0038] 3) Refer to image 3 The composition structure gradient distribution diagram of the ingot is shown. Put the composite powder into the cold isostatic pressing mold with a diameter of Φ=50mm in sequence according to the order of 1#-16#, and pass the 1mm thick matrix pure Silver powder connection;

[0039] 4) The composite powder is cold isostatically pressed into an ingot, and the molding pressure is 200MPa;

[0040] 4) Ingot hot isostatic pressing sintering, sintering pressure 600...

Embodiment 2

[0046] Embodiment 2: Silver-copper-nickel alloy sliding electrical contact material

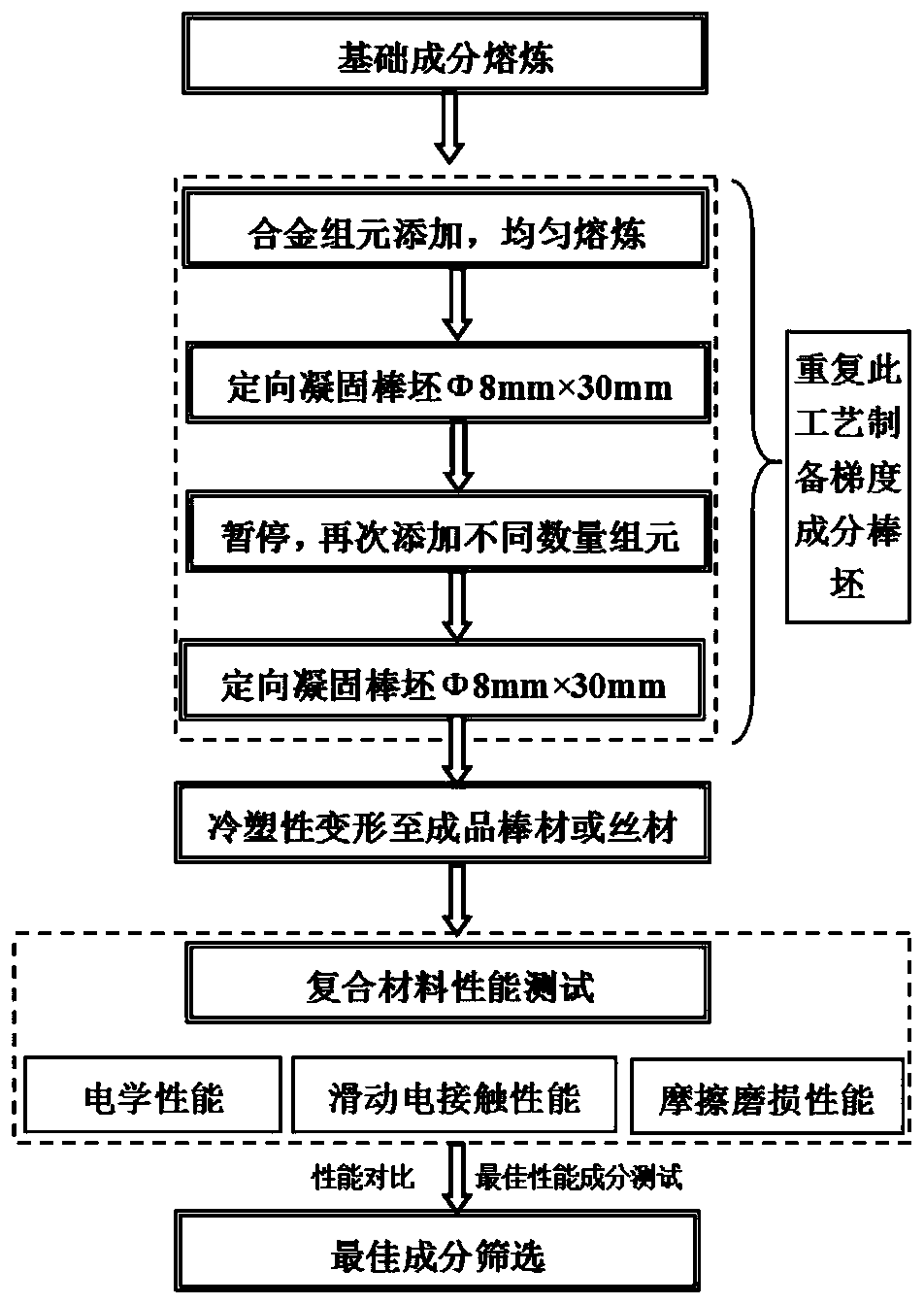

[0047] 1) Silver, copper and nickel with a purity of 99.99% are raw materials, wherein nickel powder is an added element, and the silver flakes of 1440g and the copper flakes of 160g are weighed and configured; all silver and copper are put into a directional solidification graphite crucible;

[0048] 2) Put the nickel powder that needs to be doped into the secondary feeding funnel, the flow rate of the feeding funnel is 0.1g / s, put in the nickel powder in turn according to the feeding time shown in Table 2, first put in the nickel according to the feeding time of the 1# sample pink;

[0049] 3) Inductively melt the sample at a temperature of 1200°C and keep it warm for 5 minutes;

[0050] 4) The process parameters of directional solidification are: the temperature of the cooling circulating water in the crystallizer is 25°C, the flow rate of the cooling circulating water is 400L / h, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com