Production method of extra-deep drawing hot-dip galvanized steel for automobile roofs

A technology of automobile roof and production method, which is applied in hot dip plating process, coating, metal material coating process, etc., can solve the problems of low belt speed, low pass elongation, low furnace temperature, etc., and achieve production cost Lowering, fine surface appearance, uniform color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The smelting composition is controlled as follows: C=0.0015%, Mn=0.10%, Si=0.005%, P=0.010%, S=0.007%, Als=0.039%, Ti=0.060%, N=0.0027%, O=0.0025%, The balance is Fe and other residual trace elements.

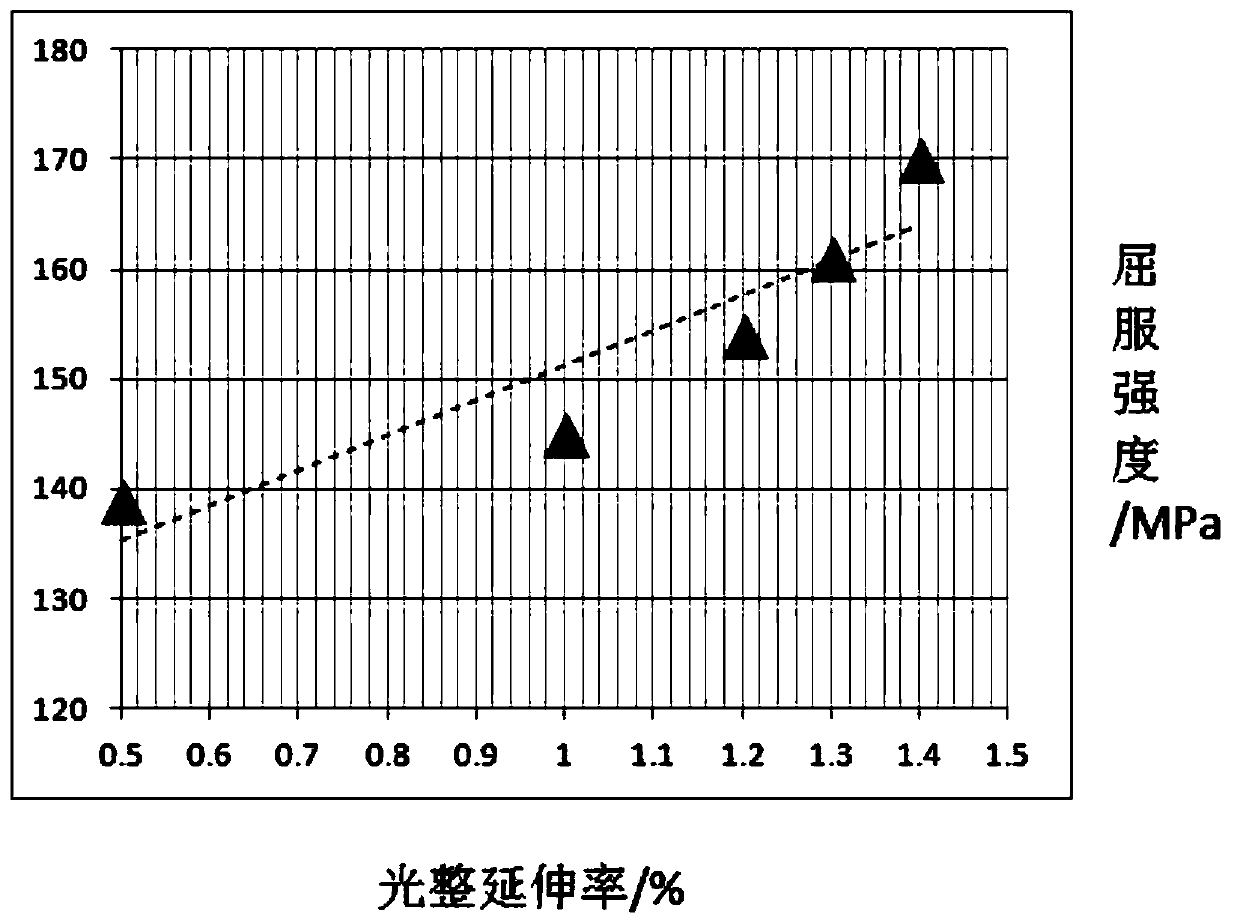

[0023] The whole process process control of Example 1 is as follows: RH refining vacuum degree 15-40pa, decarburization time 20min, argon blowing flow rate between plates 6L / min, liquid level fluctuation ± 2mm, casting speed 1.2m / min; ℃, the furnace time is 225min, U-shaped coiling is adopted, the coiling temperature is 740~750℃ within 30 meters from the head and tail, and the middle part is 720~725℃; the operating speed of the pickling process section is 200mpm, the concentration of pickling corrosion inhibitor is 1‰, cold rolling The total reduction rate is 77.0%, the surface reflectivity of the rolled steel plate is 71.0%, and the residual oil on one side is 220mg / m 2 , residual iron 35mg / m 2 The effective alkali concentration in the cleaning section of the galvaniz...

Embodiment 2

[0026] The smelting composition is controlled as follows: C=0.0018%, Mn=0.14%, Si=0.020%, P=0.015%, S=0.010%, Als=0.038%, Ti=0.069%, N=0.0025%, O=0.0030%, The balance is Fe and other residual trace elements.

[0027]The process control of the whole process of Example 2 is as follows: the vacuum degree in RH refining is 40-65pa, the decarburization time is 17min, the flow rate of argon blowing between plates is 10L / min, the liquid level fluctuation is ±2mm, the casting speed is 1.1m / min; 1226°C, furnace time 240min, U-shaped coiling, coiling temperature 750-765°C within 30 meters of head and tail, 725-733°C in the middle; operating speed of pickling process section 100mpm, pickling corrosion inhibitor concentration 1.5‰, cold The total rolling reduction rate is 85.0%, the surface reflectivity of the rolled steel plate is 70.5%, and the residual oil on one side is 218mg / m 2 , residual iron 45mg / m 2 The effective alkali concentration in the cleaning section of the galvanizing p...

Embodiment 3

[0030] The smelting composition is controlled as follows: C=0.0025%, Mn=0.20%, Si=0.006%, P=0.009%, S=0.012%, Als=0.02%, Ti=0.075%, N=0.0030%, O=0.0021%, The balance is Fe and other residual trace elements.

[0031] The process control of the whole process of Example 3 is as follows: the vacuum degree in RH refining is 95-133pa, the decarburization time is 12min, the argon blowing flow rate between plates is 3L / min, the liquid level fluctuation is ±3mm, the casting speed is 1.3m / min; 1225°C, furnace time 165min, U-shaped coiling, coiling temperature 745-762°C within 30 meters of the head and tail, 718-725°C in the middle; operating speed of pickling process section 150mpm, pickling corrosion inhibitor concentration 3‰, cold The total rolling reduction rate is 80.0%, the surface reflectivity of the rolled steel plate is 73.0%, and the residual oil on one side is 205mg / m 2 , residual iron 40mg / m 2 The effective alkali concentration in the cleaning section of the galvanizing pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com