Polyester fiber membrane-based ratio type fluorescent paper chip as well as preparation method and application thereof

A polyester fiber film and paper chip technology, applied in fluorescence/phosphorescence, material analysis through optical means, material excitation analysis, etc., can solve the problems of precision and expensive equipment, complicated pre-treatment, easy residue, etc., and achieve clear detection results Accurate, simple template elution, simple pre-treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

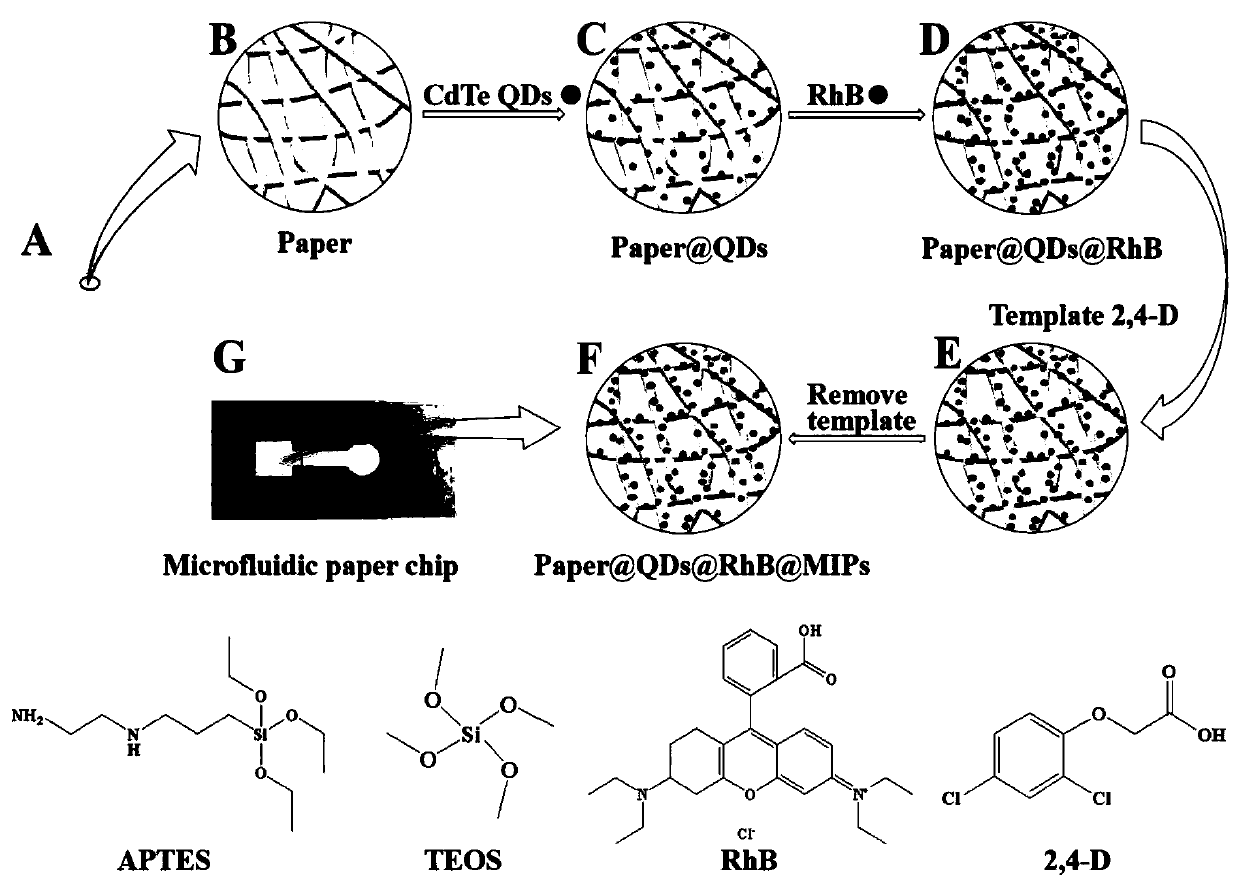

[0031] A preparation method of a ratio-type fluorescent paper chip based on a polyester fiber film, such as figure 1 shown, including the following steps:

[0032] S1: Grafting of CdTe QDs onto paper

[0033] Prepare the solution first, prepare 100mL of 1mM MES buffer solution, and make its pH 5.2, use MES buffer solution as solvent to prepare 20mL of EDC solution of 20mg / mL and 20mL of NHS solution of 10mg / L respectively, and use cut paper Cut the polyester fiber film paper, model DL42, into 1cm×1cm size with a knife, acidify with 20mL 0.2mol / L HCl, shake for 20min, pour off the HCl, and rinse with ultrapure water to remove the residual HCl solution 15mL CdTe QDs solution was mixed with 6mL EDC and shaken for 10min, poured into a petri dish with acidified fiber paper, added 6mL NHS, left for 1h and shaken for 16h, rinsed with ultrapure water three times to remove excess quantum dots. During this process, care should be taken to avoid light to prevent fluorescence quenching....

Embodiment 2

[0039] A preparation method of a ratio-type fluorescent paper chip based on a polyester fiber film, comprising the following steps:

[0040] S1: Grafting of CdTe QDs onto paper

[0041] Prepare the solution first, prepare 100mL of 1mM MES buffer solution, and make its pH 5.2, use MES buffer solution as solvent to prepare 20mL of EDC solution of 20mg / mL and 20mL of NHS solution of 10mg / L respectively, and use cut paper Cut the polyester fiber membrane paper, model DL42, into 1cm×1cm size, acidify with 20mL 0.2mol / L HCl, shake for 15min, pour off HCl, rinse with ultrapure water to remove residual HCl solution 15mL CdTe QDs solution was mixed with 6mL EDC and shaken for 10min, poured into a petri dish with acidified fiber paper, added 6mL NHS, left for 1h and shaken for 15h, rinsed with ultrapure water three times to remove excess quantum dots. During this process, care should be taken to avoid light to prevent fluorescence quenching.

[0042] S2: Preparation of MIPs

[0043]A...

Embodiment 3

[0047] A preparation method of a ratio-type fluorescent paper chip based on a polyester fiber film, comprising the following steps:

[0048] S1: Grafting of CdTe QDs onto paper

[0049] Prepare the solution first, prepare 100mL of 1mM MES buffer solution, and make its pH 5.2, use MES buffer solution as solvent to prepare 20mL of EDC solution of 20mg / mL and 20mL of NHS solution of 10mg / L respectively, and use cut paper Cut the polyester fiber film paper, model DL42, into 1cm×1cm size with a knife, acidify with 20mL 0.2mol / L HCl, shake for 25min, pour off the HCl, and rinse with ultrapure water to remove the residual HCl solution , Take 9mL CdTe QDs solution and 6mL EDC, mix and shake for 10min, pour it into a petri dish with acidified fiber paper, add 6mL NHS, let it stand for 1h, shake for 17h, rinse with ultrapure water three times to remove excess quantum dots. During this process, care should be taken to avoid light to prevent fluorescence quenching.

[0050] S2: Preparat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com