Purification method of daptomycin

A technology of daptomycin and a purification method, which is applied in the field of daptomycin purification, can solve the problems of high price, and achieve the effect of easy-to-obtain raw materials and easy industrialization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

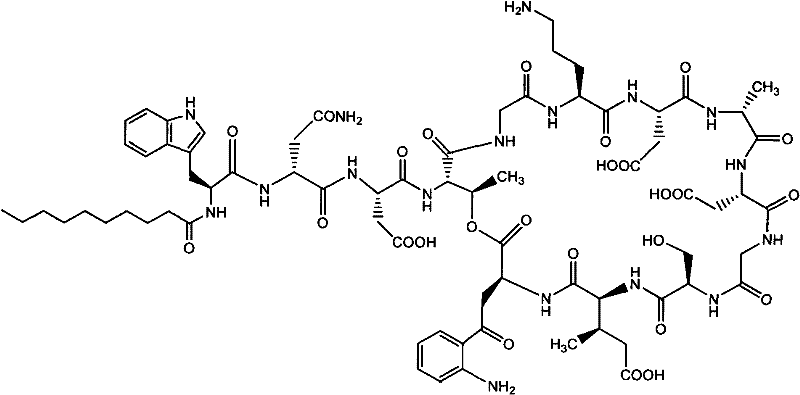

Image

Examples

Embodiment 1

[0028] The semi-purified daptomycin of embodiment 1

[0029] With reference to the Chinese invention patent application (application number 01805212.6) and its divisional application (application number 200810087401.X) and the method disclosed in U.S. Patent US6696412B1, prepare semi-purified daptomycin, as follows:

[0030] Streptomyces roseospora was fermented under controlled conditions to obtain a daptomycin fermentation liquid. The fermentation broth is centrifuged or filtered to obtain a clear solution. The clarified fermentation broth was applied to anion exchange resin Mitsubishi FP-DA13, then washed with 0.03 mol / L NaCl at pH 6.5, and eluted with 0.3 mol / L NaCl at pH 6.5. Load the eluent onto the reverse phase resin HP-20ss, wash the HP-20ss column with 45% isopropanol, and elute with 55-60% isopropanol, and the purity of the liquid phase is about 90% by HPLC detection semi-purified daptomycin solution.

Embodiment 2

[0031] The daptomycin of embodiment 2 purification

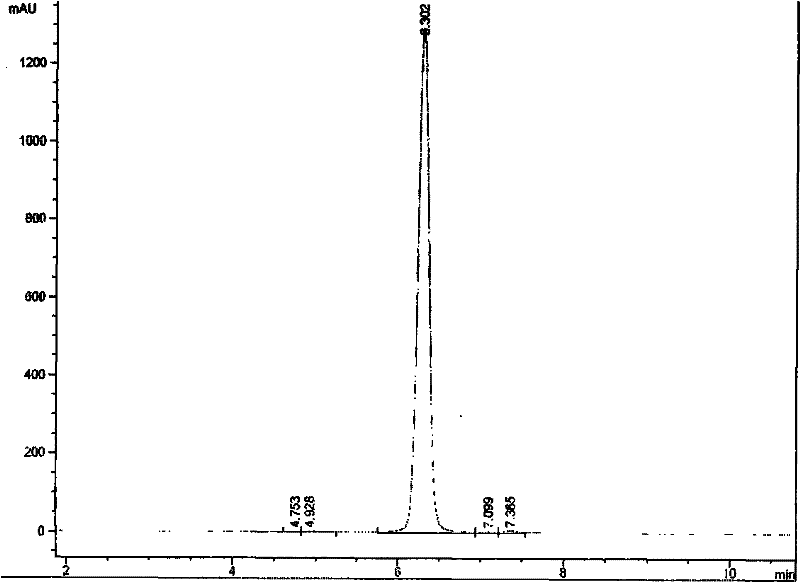

[0032] According to the method of Example 1, a semi-purified daptomycin solution with a liquid phase purity of 90% was obtained, which was loaded onto Sephadex A25, which was pre-balanced with pH 7.0 acetate buffer. After daptomycin is bound to the resin, wash with 3 times column volume of pH 7.0 acetate buffer, and then use 10 times column volume of pH 7.0 acetate buffer containing 0.5mol / L NaCl to elute to obtain purified Daptomycin totomycin. Adopt HPLC to detect the purity of daptomycin, the result is 98.6%, as figure 2 shown.

Embodiment 3

[0033] The daptomycin of embodiment 3 purification

[0034] The semi-purified daptomycin solution with a liquid phase purity of 91% obtained according to the method in Example 1 was loaded onto Sephadex A25, which had previously used a pH 6.0 acetate buffer containing 2 mol / L urea balance. After daptomycin is bound to the resin, wash with 3 times column volume of pH 6.0 acetate buffer containing 2mol / L urea, and then use 10 times column volume of pH 6.0 buffer solution containing 0.2mol / L NaCl and 2mol / L urea Elute with acetic acid buffer, and detect by HPLC to obtain daptomycin with a purity of 98.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com