A roll-type lead-acid battery and its preparation method and application

A lead-acid battery, roll-type technology, applied in lead-acid batteries, lead-acid battery construction, lead-acid battery electrodes, etc., can solve the problems of increased internal resistance, inactivation of active substances, low power utilization efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

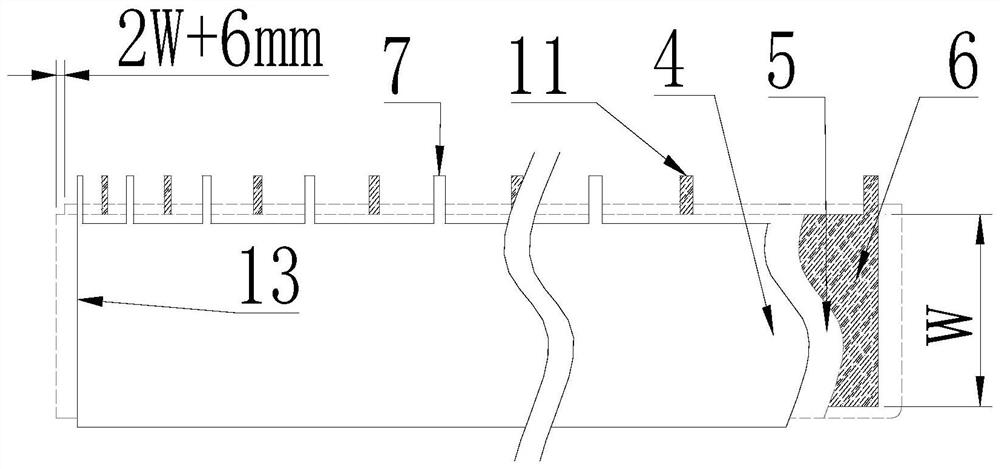

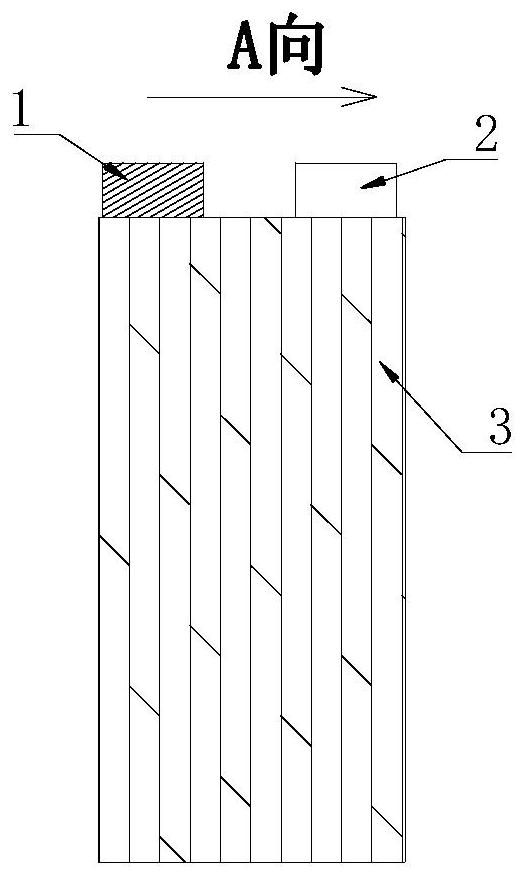

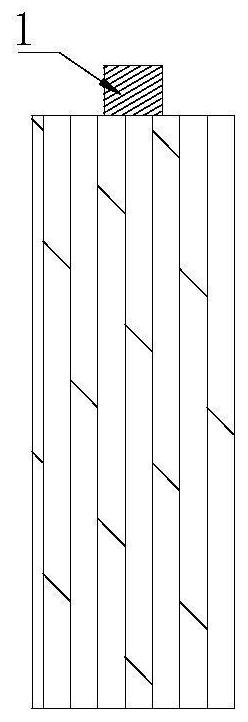

[0095] Example 1 (the metal barium plate accounts for 10% in the composite plate C, the lead-barium alloy plate containing 1% barium accounts for 90%, the barium element in the pole plate accounts for 10.9%, and the number of winding layers in the inner core of the single cell battery is n=60)

[0096] (1) 107.50g of analytically pure barium granules were smelted and poured to obtain a barium bar with a specification of 20mm×4mm×40mm and containing 99.95% of barium; 9.68g of analytically pure barium granules were mixed with 957.8g of analytically pure lead granules, melted and casted to obtain The specification is 20mm × 4mm × 40mm, and the lead-barium alloy bar containing 1% barium; under nitrogen atmosphere, the barium bar containing 99.95% barium is rolled into a 0.2mm thick metal barium plate with a boron glass material pressure roller, and A is obtained. Plate, the lead-barium alloy strip containing 1% barium is rolled into a lead-barium alloy plate with a thickness of 0.1...

Embodiment 2

[0110] Example 2 (the metal barium plate accounts for 5% in the composite plate C, the lead-barium alloy plate containing 1% barium accounts for 95%, the barium element accounts for 5.95% in the pole plate, and the number of layers of the inner core of the single cell battery n=60)

[0111] (1) Melting and pouring 50.90g of analytically pure barium particles to obtain a barium bar with a specification of 20mm×4mm×40mm and containing 99.95% of barium; mixing 9.67g of analytically pure barium particles with 957.43 of analytically pure lead particles, melting and pouring, to obtain specifications 20mm×4mm×40mm, lead-barium alloy strip containing 1% barium; under nitrogen atmosphere, roll the barium strip containing 99.95% barium into a 0.14mm thick metal barium plate with a boron glass material pressure roller to obtain A plate , the lead-barium alloy strip containing 1% barium is rolled into a lead-barium alloy plate with a thickness of 0.32mm, the same width as that of plate A, ...

Embodiment 3

[0119] Example 3 (the metal barium plate accounts for 3% in the composite plate C, the lead-barium alloy plate containing 1% barium accounts for 97%, the barium element accounts for 3.97% in the pole plate, and the number of negative plates of the single cell battery is n=60)

[0120] (1) 29.91g of analytically pure barium granules were smelted and poured to obtain a barium bar with a specification of 20mm×4mm×40mm containing 99.95% of barium; 9.67g of analytically pure barium granules were mixed with 957.43g of analytically pure lead granules, melted and casted to obtain The specification is 20mm × 4mm × 40mm, and the lead-barium alloy bar containing 1% barium; under nitrogen atmosphere, the barium bar containing 99.95% barium is rolled into a 0.1mm thick metal barium plate with a boron glass material pressure roller, and A is obtained. Roll the lead-barium alloy strip containing 1% barium into a lead-barium alloy plate with a thickness of 0.55 mm, the same width as plate A, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com