A kind of nimobnb-based separator multilayer composite structure material and preparation method thereof

A multi-layer composite and structural material technology, applied in the direction of chemical instruments and methods, layered products, metal processing equipment, etc., can solve the problems of easy clogging, damage and corrosion of separators, and achieve stable friction performance and corrosion resistance , good compatibility and large carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

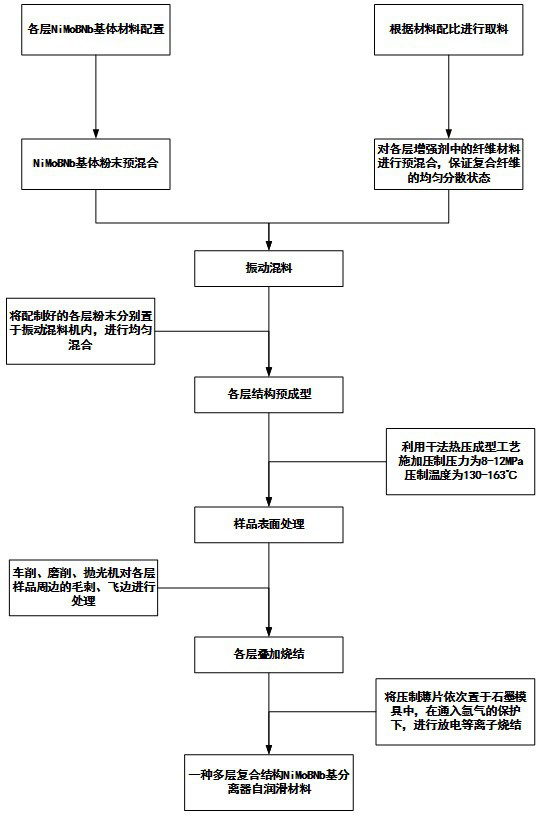

[0032] like figure 1 Shown, a kind of NiMoBNb-based separator multilayer composite structure material and its preparation process mainly contain the following steps:

[0033] 1) The multilayer structure of a NiMoBNb-based separator is a three-layer composite structure, and the thickness ratio of each layer is calculated by mass percentage: the thickness of the top layer is 4%, the thickness of the middle layer is 35%, and the thickness of the bottom layer is 61%.

[0034] 2) According to the different mass percentages of the components in each layer of the raw material of the separator, the required material ratio is calculated; the top layer is 7% NiMoBNb alloy, 29% anti-wear agent, 9% heat conduction agent, 30% reinforcing agent, and 25% curing agent ; The middle layer is 20% NiMoBNb alloy, 10% anti-wear agent, 12% heat conduction agent, 40% reinforcing agent, and 18% curing agent. The bottom layer is all NiMoBNb alloy.

[0035] 3) According to the mass ratio of the above-...

Embodiment 2

[0043] like figure 1 Shown, a kind of NiMoBNb-based separator multilayer composite structure material and its preparation process mainly contain the following steps:

[0044] 1) The multilayer structure of a NiMoBNb-based separator is a three-layer composite structure, and the thickness percentage of each layer is 7% of the top layer thickness, 30% of the middle layer thickness, and 63% of the bottom layer thickness.

[0045] 2) According to the different mass percentages of the components in each layer of the raw material of the separator, the required material ratio is calculated; the top layer contains 8% NiMoBNb alloy, 32% anti-wear agent, 12% heat conduction agent, 26% reinforcing agent, and 22% curing agent ; The middle layer contains 25% NiMoBNb alloy, 16% anti-wear agent, 9% thermal conductivity agent, 36% reinforcing agent and 14% curing agent. The bottom layer is a pure NiMoBNb alloy.

[0046] 3) According to the mass ratio of the above-mentioned NiMoBNb alloy in e...

Embodiment 3

[0054] like figure 1 Shown, a kind of NiMoBNb-based separator multilayer composite structure material and its preparation process mainly contain the following steps:

[0055] 1) The multilayer structure of a NiMoBNb-based separator is a three-layer composite structure, and the thickness ratio of each layer is calculated by mass percentage: the thickness of the top layer is 9%, the thickness of the middle layer is 42%, and the thickness of the bottom layer is 49%.

[0056]2) According to the different mass percentages of the components in each layer of the raw material of the separator, the ratio of the required raw materials is calculated; the top layer contains 10% NiMoBNb alloy, 42% anti-wear agent, 9% heat transfer agent, 21% reinforcing agent, and 18% curing agent ; The middle layer contains 20% NiMoBNb alloy, 17% anti-wear agent, 10% thermal conductivity agent, 42% reinforcing agent, and 11% curing agent. The bottom layer is all NiMoBNb alloy.

[0057] 3) According to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com