Bridge self-repairing paving method based on cement-based composite material

A composite material and composite material component technology, applied in the field of bridge self-healing pavement, can solve the problems of high repair construction complexity, low maintenance effect stability, low repair efficiency, etc., so as to reduce maintenance time, high construction efficiency, and low cost The effect of chemical adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

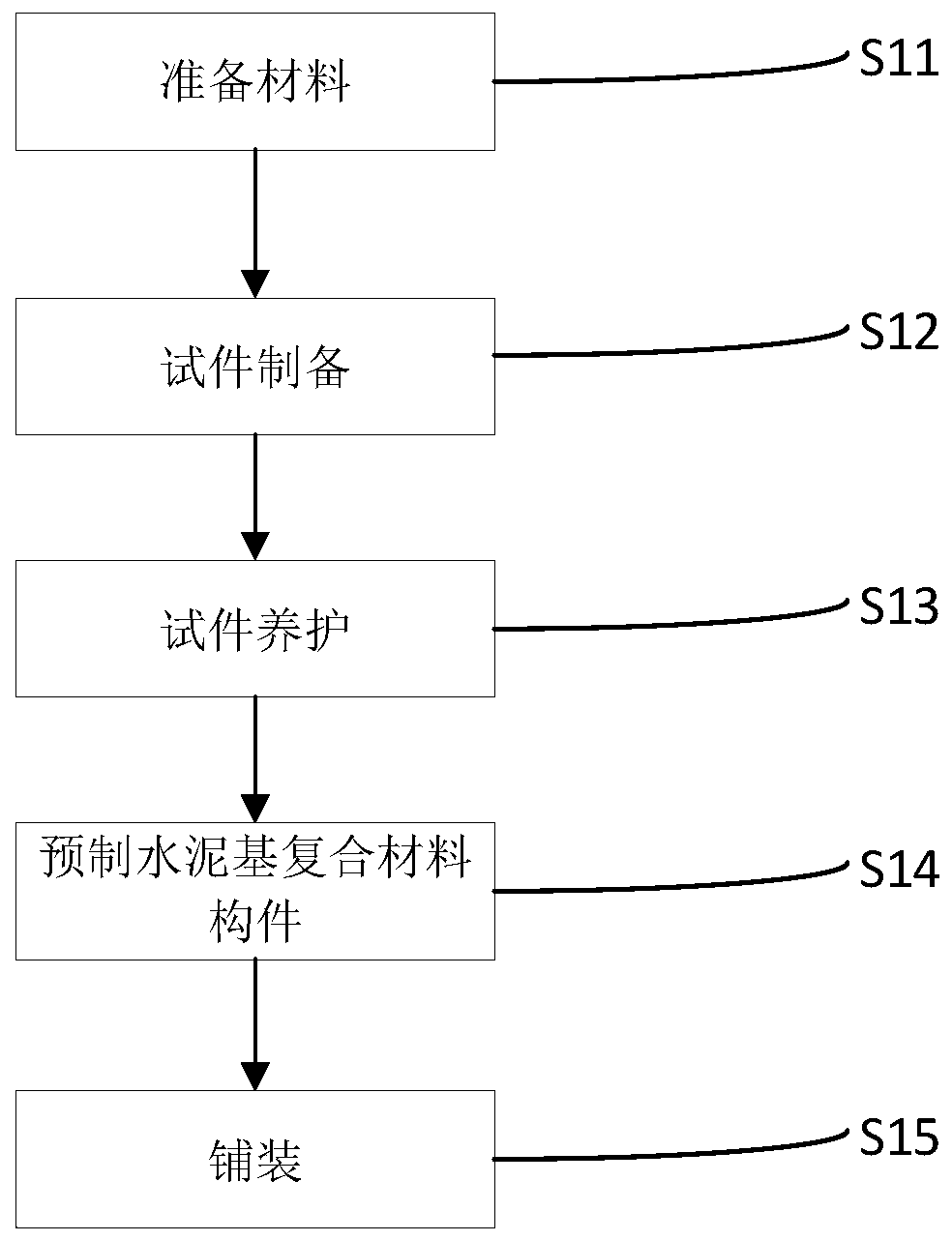

[0085] 1. Preparation method

[0086] 1. Material preparation:

[0087] The main raw materials for preparing cement-based composite materials include cement, fly ash, rubber powder, quartz sand, polyvinyl alcohol fiber, superplasticizer and water. The cement used in this paper is the Conch brand P42.5R Portland cement produced by China Cement Factory; the fly ash is the first-grade fly ash of Nanjing Thermal Power Plant; the quartz sand is provided by Nanjing Ningliu Quartz Filter Company, and the particle size is 80 mesh-150 mesh; rubber powder particle size is 40 mesh-80 mesh; high-efficiency water reducer is carboxylic acid-based water reducer.

[0088] 2. Test piece preparation

[0089] The material ratio is cement: fly ash: rubber powder: quartz sand: polyvinyl alcohol fiber: superplasticizer: water = 1:2:1:0.36:0.02:0.03:0.25. During the slurry forming process, first weigh the fly ash, cement, quartz sand, and rubber powder, then pour them into the mortar mixer and st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com