Spectrum calibration structure based on gradual changing optical microcavity, and preparation method

An optical microcavity, spectral calibration technology, applied in spectrometry/spectrophotometry/monochromator, optical radiation measurement, radiation pyrometry, etc., can solve problems such as offset, achieve good stability, Good applicability and improved portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

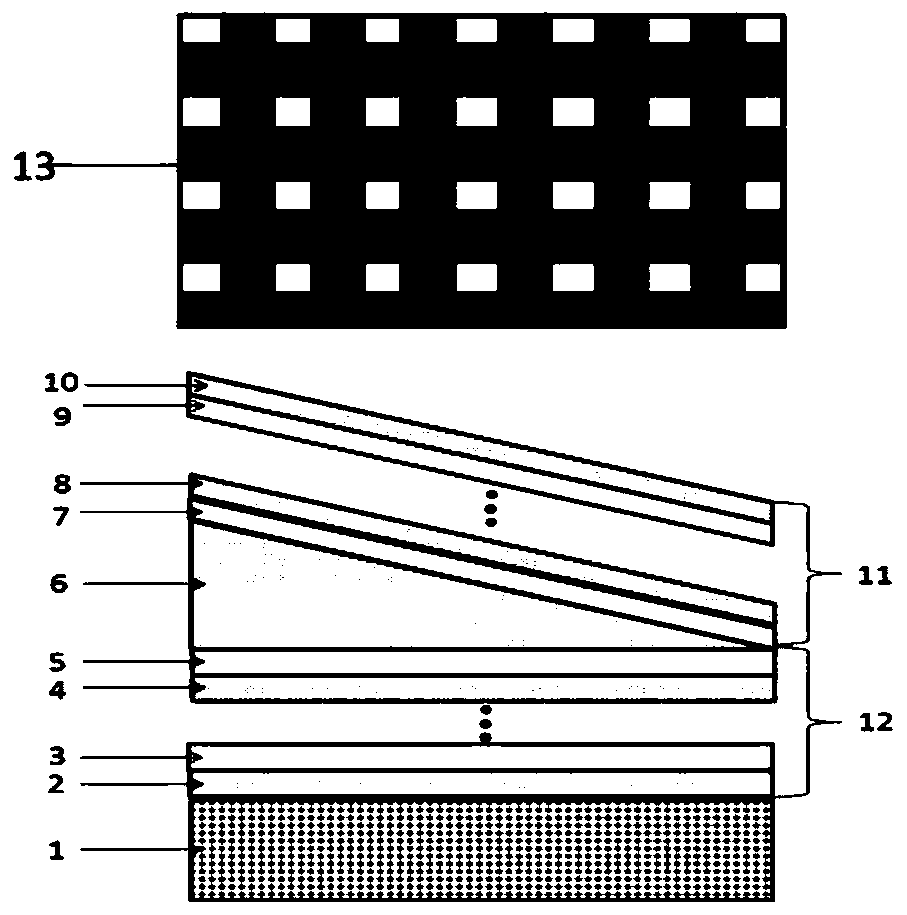

[0038] The invention provides a spectral calibration structure based on a graded optical microcavity, such as figure 1 As shown, it includes a substrate 1, on which a lower DBR 12, an intermediate cavity layer 6, an upper DBR 11 and a top unit 13 are sequentially arranged; wherein, the DBR is a Distributed Bragg Reflector, a distributed Bragg reflector. Simply irradiating monochromatic light sources on different units can quickly and accurately obtain smooth and accurate spectral curves, thereby determining the spectral wavelength position and spectral stability, and correcting wavelength shift. According to different design requirements, the narrow-band peak position at any wavelength can be obtained.

[0039] Specifically, both the lower DBR 12 and the upper DBR 11 include several high-refractive-index materials and low-refractive-index materials alternately arranged, such as figure 1 As shown, that is, the lower layer DBR 12 includes high refractive index material 2 and lo...

Embodiment 2

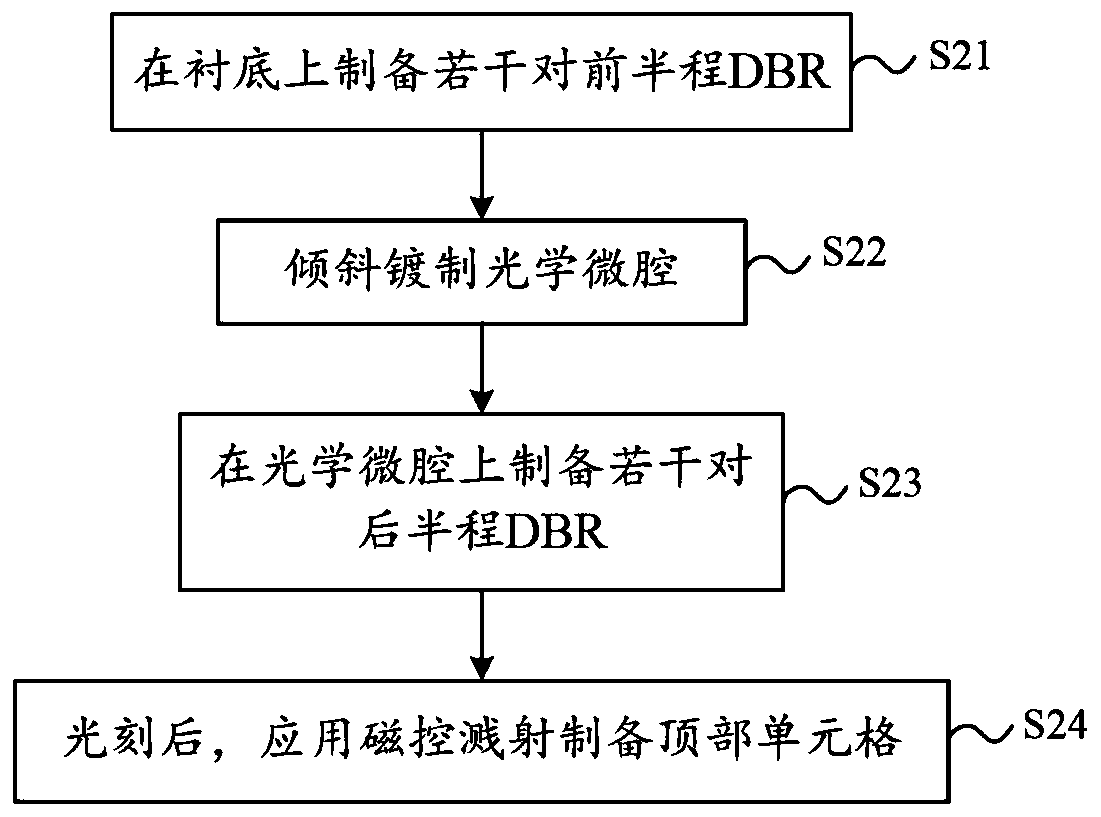

[0047] The invention provides a method for preparing a spectral calibration structure based on a graded optical microcavity, and the flow chart is as follows figure 2 shown, including:

[0048] Step S21, preparing several pairs of first-half DBRs on the substrate;

[0049] Step S22, obliquely plating the optical microcavity;

[0050] Step S23, preparing several pairs of second-half DBRs on the optical microcavity;

[0051] Step S24 , after photolithography, the top cells are prepared by magnetron sputtering.

[0052] (1) The spectral calibration structure of the spectral peak at 615nm-650nm gradient optical microcavity

[0053] According to the embodiment of the present invention, the spectral calibration structure design and structure of the spectral peak at 615nm-650nm gradient optical microcavity include the following steps:

[0054] The first step: through the Leybold visible optical coating machine, with K9 glass as the substrate, Ta 2 o 5 , SiO 2 Prepare 8 pairs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com