Method for achieving even pattern array during ink-jet printing

An inkjet printing and uniform pattern technology, applied in the field of inkjet printing, can solve the problems of limited application and achieve good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

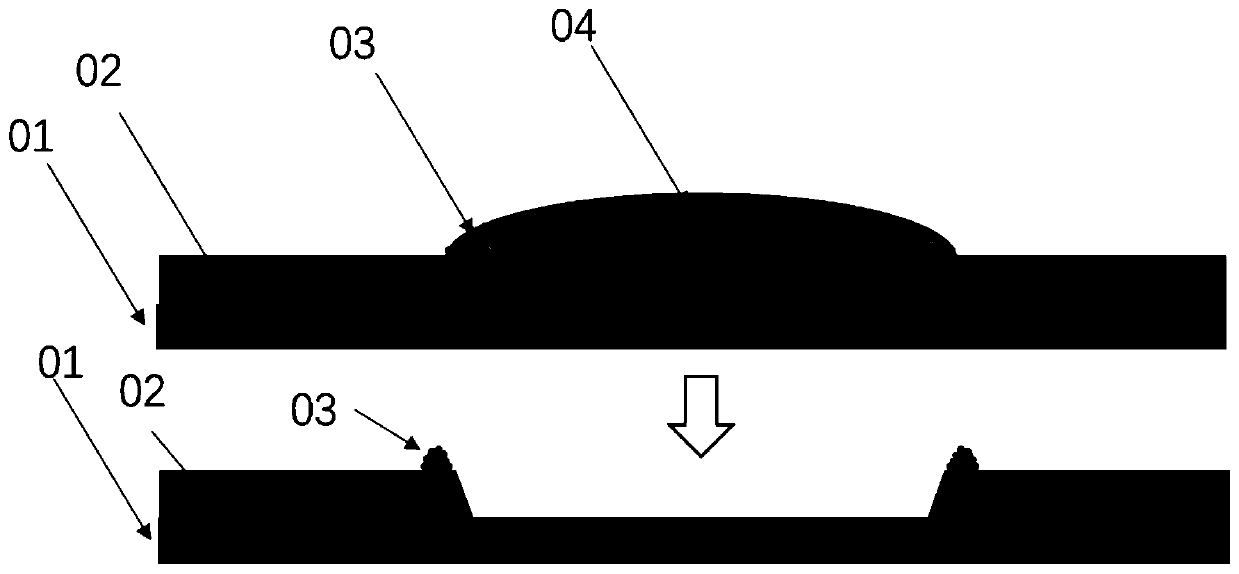

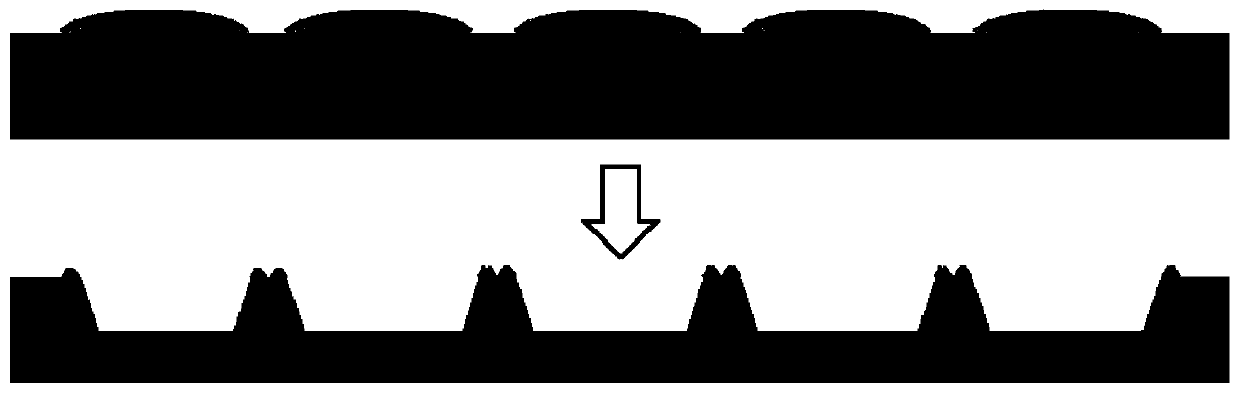

Method used

Image

Examples

Embodiment

[0023] (1) At room temperature, clean the glass substrate sequentially with tetrahydrofuran, isopropanol, lotion, deionized water (twice), and ultrasonic cleaning in isopropanol. The cleaning time of each step is 10 minutes, and then place the cleaned glass substrate on Dry in a constant temperature oven at 75°C. Then the glass substrate was treated with oxygen Plasma for 10 min at room temperature to remove surface impurities and increase the surface energy of the substrate.

[0024] (2) Spin-coat one deck of PVP solution (500mg PVP powder+0.1ml methylated polymelamine co-formaldehyde in 5ml ethylene glycol solution to obtain 100mg / ml PVP solution on the treated glass substrate with a homogenizer at room temperature. solution), the spin-coating conditions are: the rotation speed is 3000 rpm, and the time is 30s. After the spin coating, the sample was cured with a UV curing machine for 3 minutes to obtain a PVP polymer film.

[0025] (3) A Dimatix 2800 series piezoelectric i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com