Preparation method of microbiological corrosion resistant A1N/Ti ceramic metal composite coating

A ceramic metal, microorganism-resistant technology, applied in the direction of metal material coating process, coating, non-metallic elements, etc., to achieve strong local corrosion resistance, improve corrosion resistance, and prevent corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

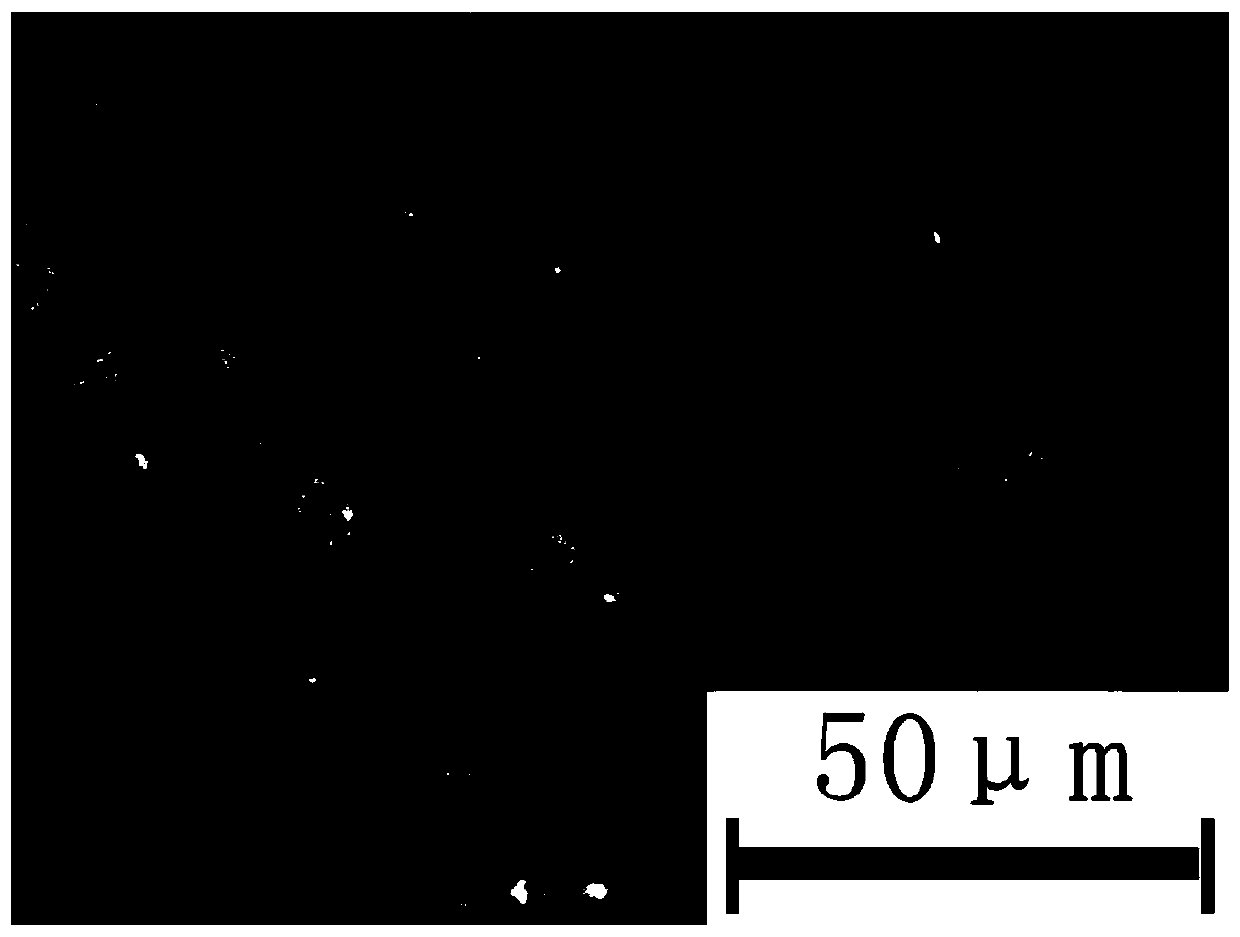

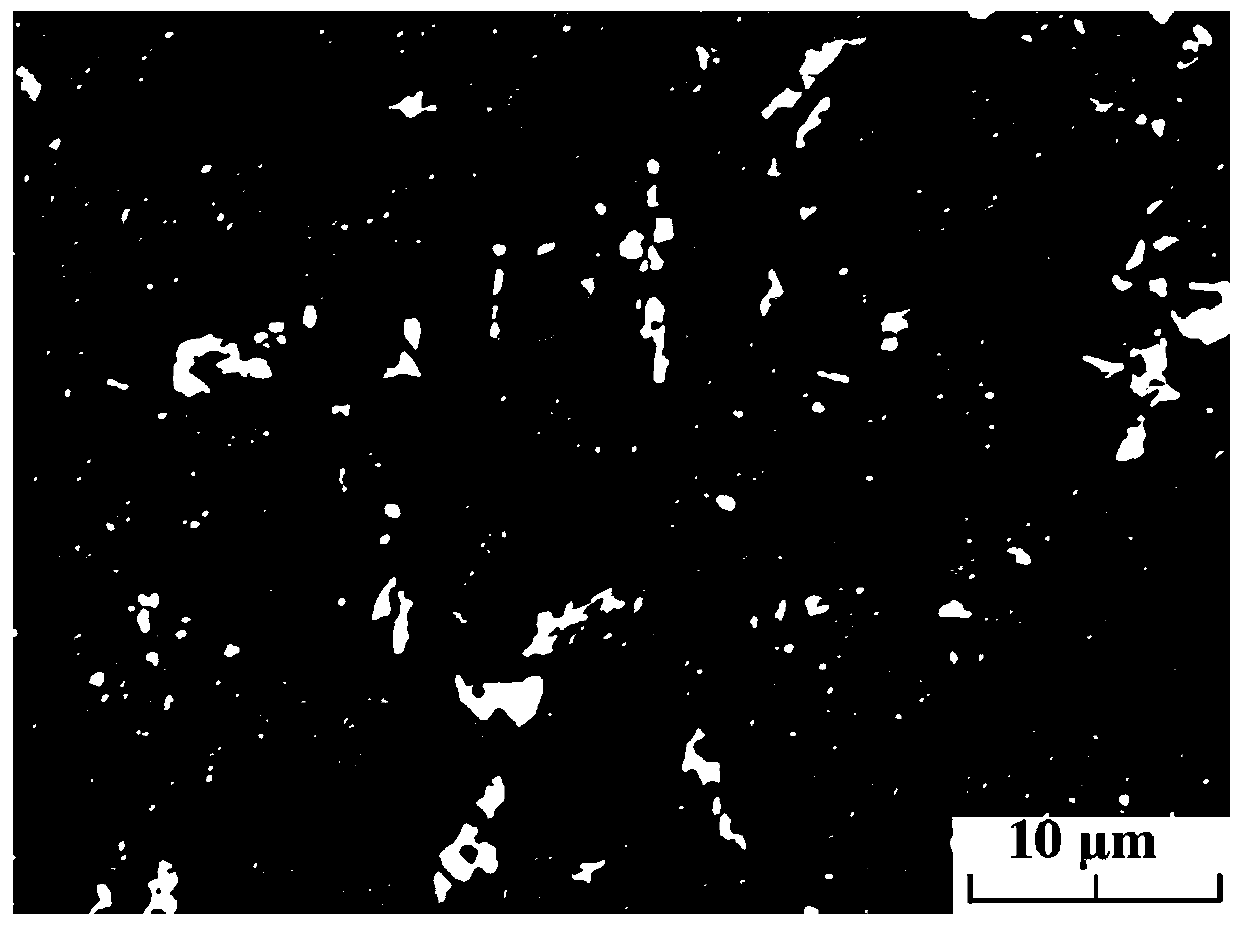

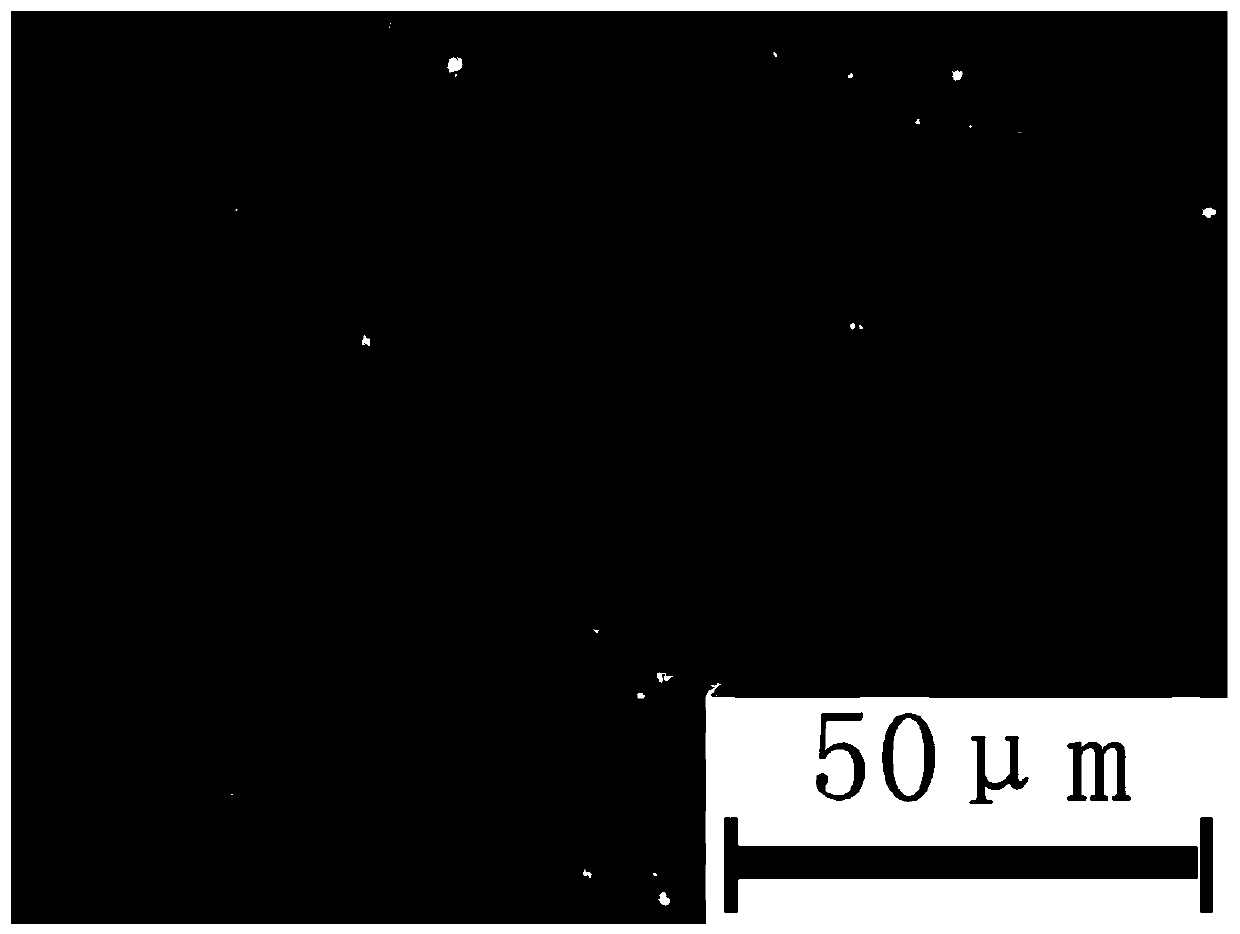

Image

Examples

Embodiment 1

[0029] The preparation method of the anti-microbial corrosion AlN / Ti ceramic-metal composite coating of the present embodiment comprises the following steps:

[0030] Step 1. Prepare AlN particles by carbothermal reduction method. The specific method is: weigh alumina and carbon black according to the mass ratio of 73:27, place the weighed alumina and carbon black in a wet ball mill for wet ball milling, Then dry the material after wet ball milling and place it in an atmosphere furnace, raise the temperature to 1400° C. at a rate of 10° C. / min under a flowing nitrogen atmosphere with a flow rate of 5 L / min, and keep it warm for 4 hours to obtain AlN particles; The mass purity of aluminum is not less than 99%, the average particle size of aluminum oxide is not greater than 30μm; the carbon content of the carbon black is not less than 99%, and the average particle size of carbon black is not greater than 200nm; the mass of AlN in the AlN particles is 100% AlN content is not less...

Embodiment 2

[0036] The preparation method of the anti-microbial corrosion AlN / Ti ceramic-metal composite coating of the present embodiment comprises the following steps:

[0037] Step 1. Prepare AlN particles by carbothermal reduction method. The specific method is: weigh alumina and carbon black according to the mass ratio of 73:27, place the weighed alumina and carbon black in a wet ball mill for wet ball milling, Then dry the material after wet ball milling and place it in an atmosphere furnace, raise the temperature to 1400° C. at a rate of 12° C. / min under a flowing nitrogen atmosphere with a flow rate of 5 L / min, and keep it warm for 4 hours to obtain AlN particles; The mass purity of aluminum is not less than 99%, the average particle size of aluminum oxide is not greater than 30μm; the carbon content of the carbon black is not less than 99%, and the average particle size of carbon black is not greater than 200nm; the mass of AlN in the AlN particles is 100% AlN content is not less...

Embodiment 3

[0042] The preparation method of the anti-microbial corrosion AlN / Ti ceramic-metal composite coating of the present embodiment comprises the following steps:

[0043] Step 1. Prepare AlN particles by carbothermal reduction method. The specific method is: weigh alumina and carbon black according to the mass ratio of 73:27, place the weighed alumina and carbon black in a wet ball mill for wet ball milling, Then dry the material after wet ball milling and place it in an atmosphere furnace, raise the temperature to 1400° C. at a rate of 15° C. / min under a flowing nitrogen atmosphere with a flow rate of 5 L / min, and keep it warm for 4 hours to obtain AlN particles; The mass purity of aluminum is not less than 99%, the average particle size of aluminum oxide is not greater than 30μm; the carbon content of the carbon black is not less than 99%, and the average particle size of carbon black is not greater than 200nm; the mass of AlN in the AlN particles is 100% AlN content is not less...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com