Fixed bed reactor and unsaturated light hydrocarbon hydrogenation method

A fixed bed reactor and reactor technology, which are applied in chemical instruments and methods, hydrogenation to hydrocarbons, sustainable manufacturing/processing, etc., can solve the problem of inability to effectively control reaction temperature, increase equipment investment and energy consumption, and catalyst bed temperature. It can effectively control the temperature of the catalyst bed, reduce the operating cost, and reduce the circulating flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

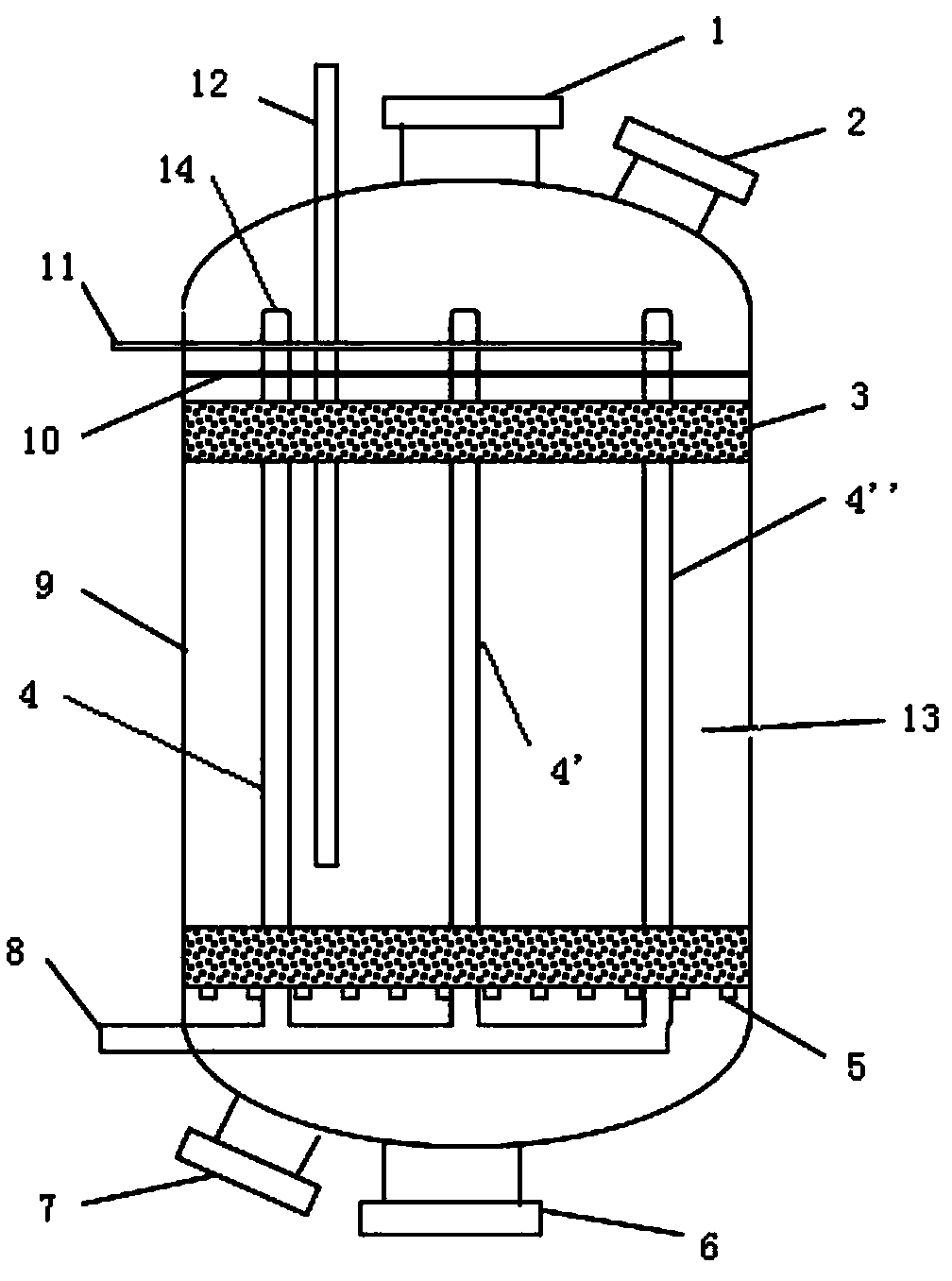

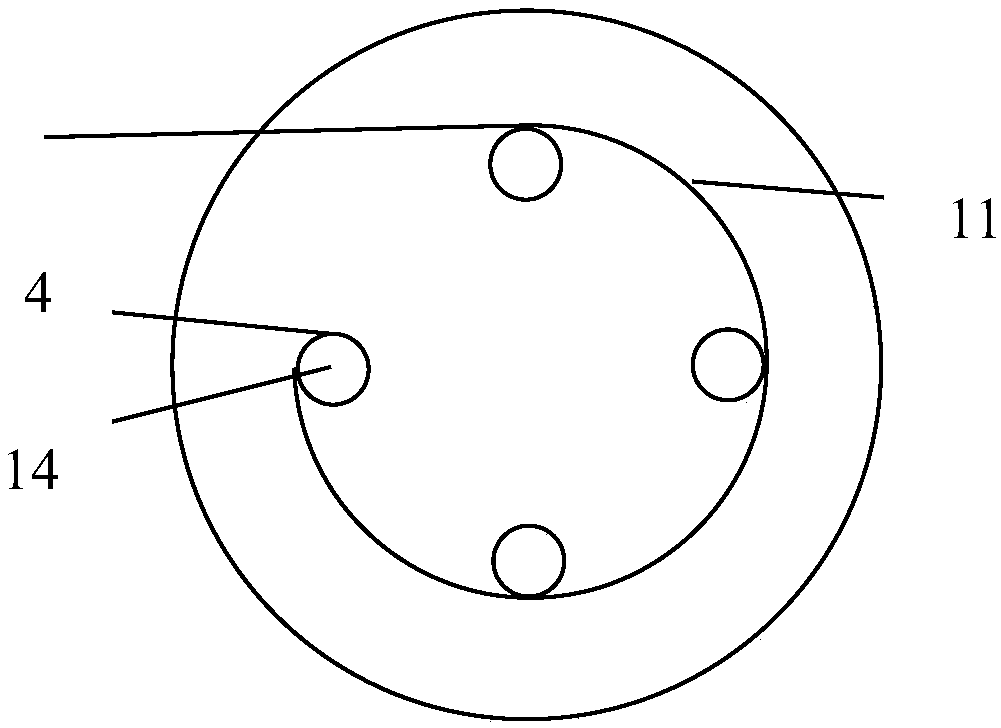

[0059] This embodiment adopts figure 1 The reactor shown carries out the hydrogenation reaction of C4-C6 unsaturated light hydrocarbons.

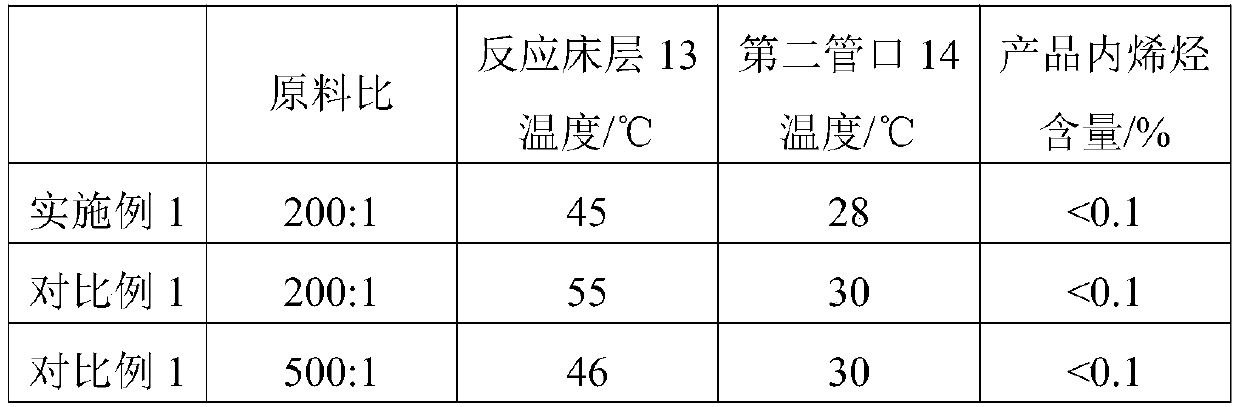

[0060] Fill the reactor with 5m 3 YN-1 hydrofining catalyst, each heat exchange tube is filled with 0.1m 3 YN-1 hydrorefining catalyst. The unsaturated carbon four raw materials containing butadiene and butene and hydrogen are fed into the reactor from inlet 1 at a volume ratio of 200:1. The reaction temperature of the reactor is 30°C and the pressure is 2.7MPa. The reaction product is discharged from the outlet 6 of the reactor. At the same time, the cooled carbon four hydrogenation product enters from the first nozzle of the heat exchange tube at the lower part of the reactor, the temperature is 20° C., and the pressure is 2.7 MPa. Record the temperature of the catalyst bed 13 and the temperature of the second nozzle of the heat exchange tube 4. Analyze the olefin content in the product. The specific values are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com