Oxysulfide elastic mechanoluminescence material and preparation method thereof

A technology of elastic stress and luminescent materials, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., which can solve the problems of less types of elastic stress luminescent materials, high luminous intensity of elastic stress luminescent materials, and difficulty in meeting application requirements, etc. The conditions are easy to control , low equipment requirements and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0028] Select strontium carbonate, zinc sulfide and transition metal carbonates or rare earth ion oxides as raw materials, weigh the raw materials according to the molar ratio of each element (as shown in Table 1), put the above raw materials into an agate mortar and grind, mix well Finally, take an appropriate amount of sample and put it into the corundum crucible, then put the crucible into the corundum boat, push the corundum boat into the tube furnace, raise the temperature to 1000°C for 24 hours under the protective atmosphere of pure argon, and keep the temperature with the furnace. Allow to cool naturally. Grind the cooled sample for 10-30 minutes to obtain an oxygen-sulfur compound-based stress-luminescent powder.

[0029] The sample proportioning of table 1 embodiment 1~3

[0030]

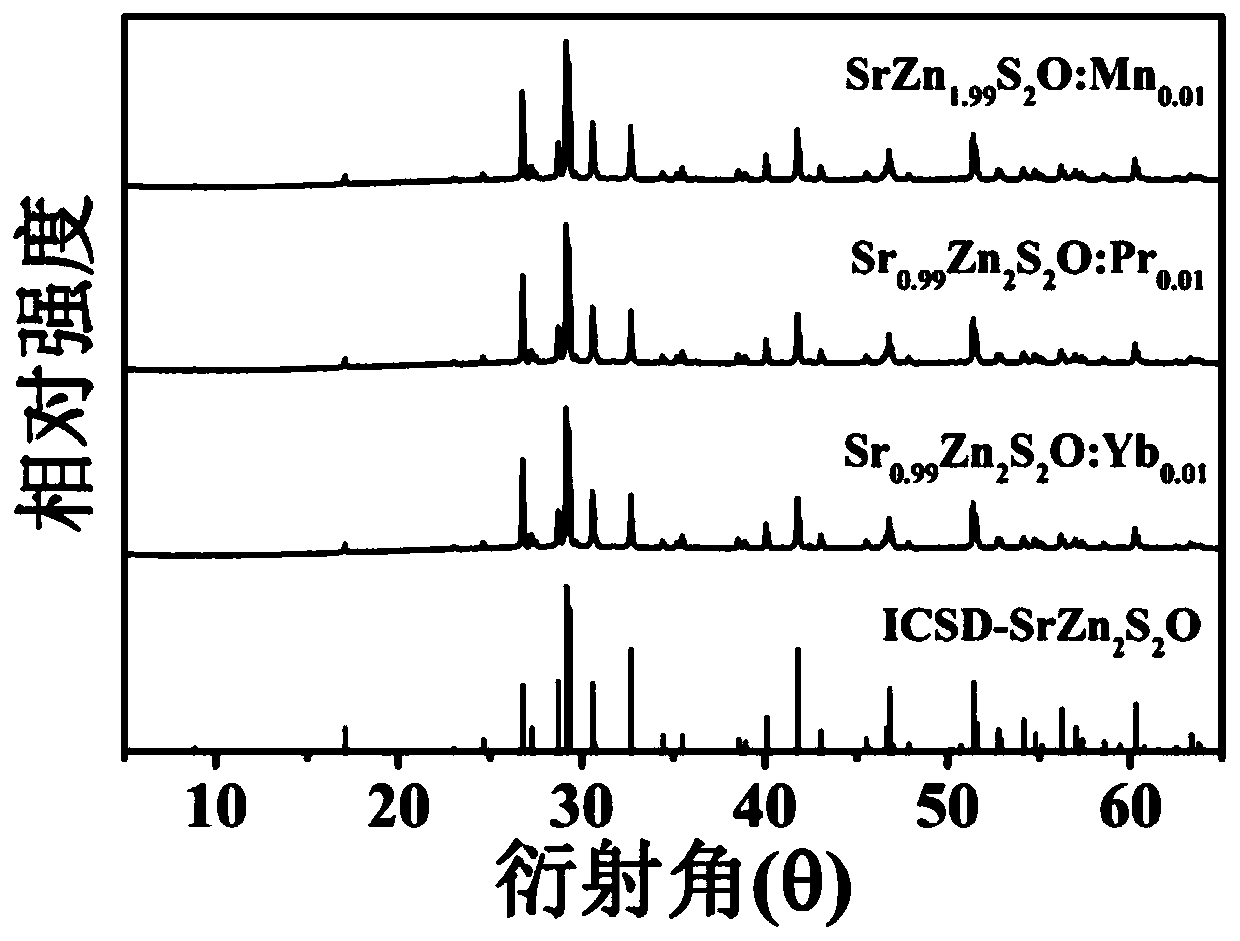

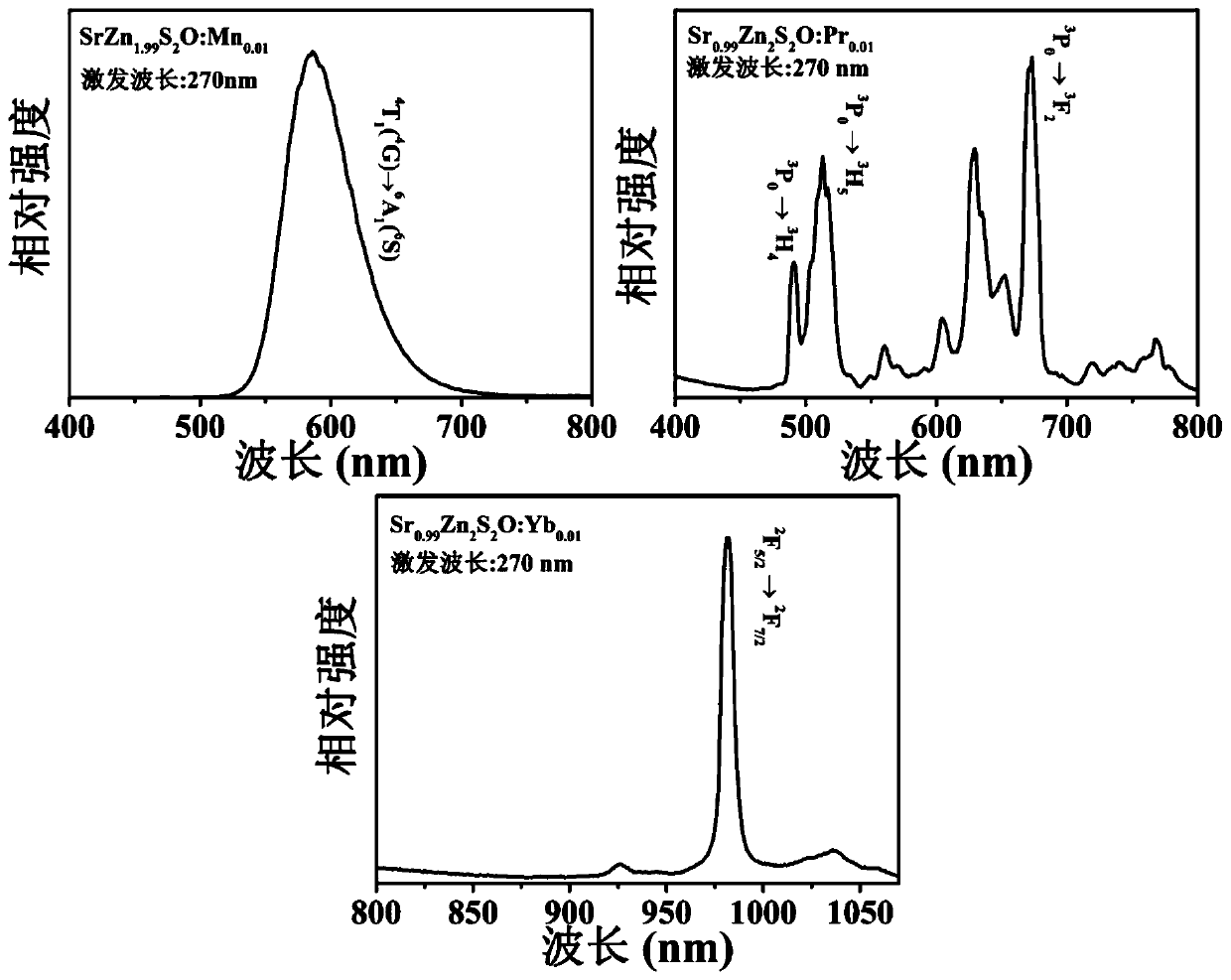

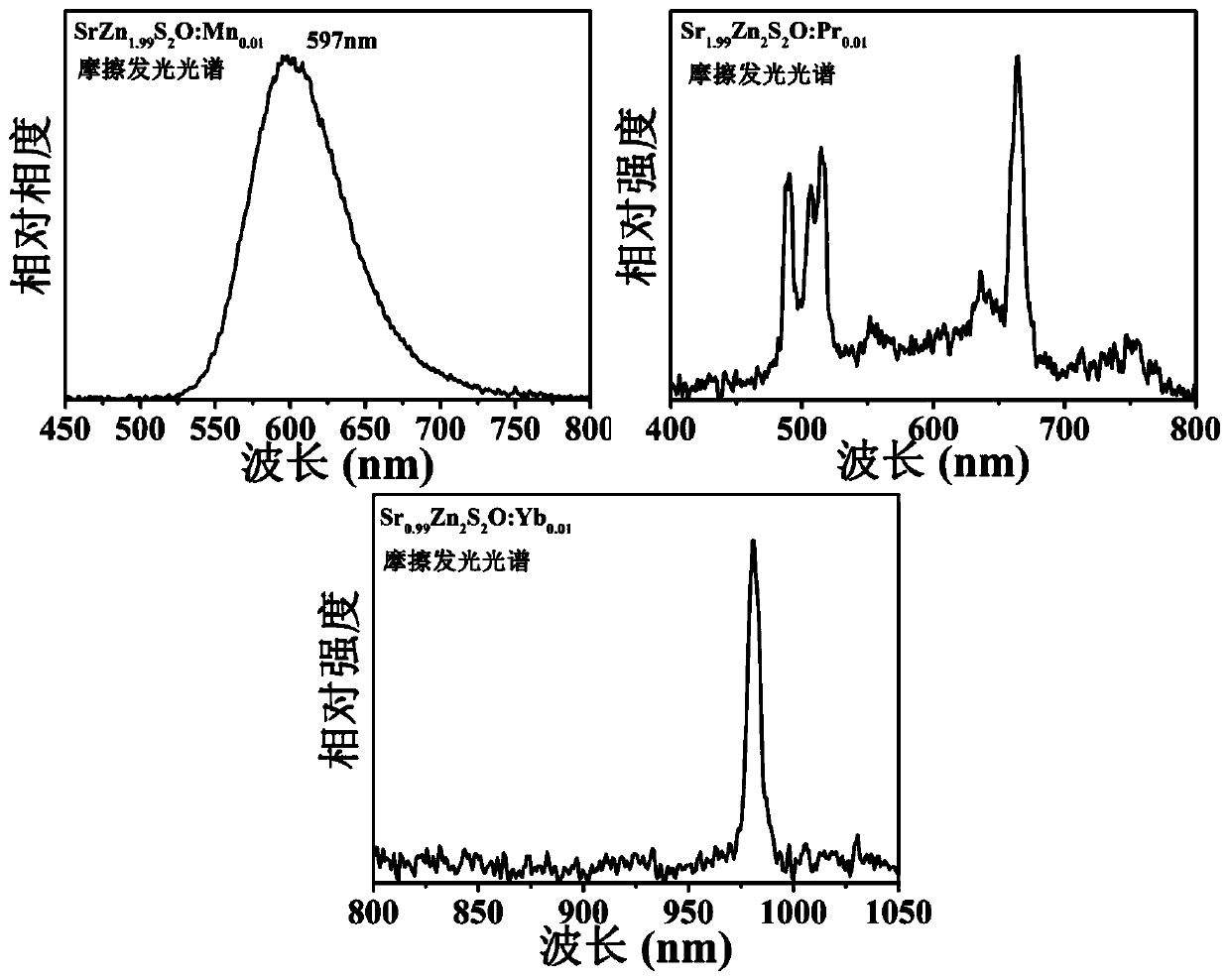

[0031] figure 1 Prepare the X-ray diffraction figure of sample for embodiment 1~3, spectral line adopts Bruker d8-advance bruker X-ray diffractometer to measure, test voltage 40kv, te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com