Electrolyte, battery containing same, and electric vehicle

An electrolyte and lithium-ion battery technology, applied in the field of lithium-ion batteries and electric vehicles, can solve problems such as poor high-voltage cycle performance, and achieve the effects of improving oxidation decomposition potential, good cycle life and capacity retention rate, and good anti-oxidation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] Since the preparation process of the negative electrode sheet, the positive electrode sheet, and the separator are well-known technologies in the art, and the assembly of the battery is also a well-known technology in the art, details will not be repeated here.

[0043] According to the lithium ion battery proposed by the present invention, preferably, the active material of the positive electrode contains the ternary positive electrode material LiNi x co y A 1-x-y o 2 , A is one or more of Mn or Al, 0.33≤x≤0.85, 0.075≤y≤0.33. Preferably, the active material of the positive electrode is a high-voltage positive electrode active material, such as an active material working at a voltage higher than 4.5V. The active material of the positive electrode can be selected from LiNi, for example 0.5 co 0.2 mn 0.3 o 2 , LiNi 0.6 co 0.2 mn 0.2 o 2 , LiNi 0.8 co 0.1 mn 0.1 o 2 , LiNi 0.85 co 0.075 mn 0.075 o 2 , LiNi 0.8 co 0.15 Al 0.05 o 2 One or more of them,...

Embodiment 1

[0052] (1) Preparation of electrolyte:

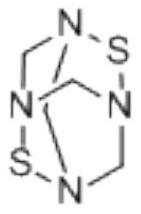

[0053] 60g ethylene carbonate and 140g diethyl carbonate are mixed into mixed solvent, add 30g in mixed solvent, the LiPF of 1mol / L 6 . Then 2.14 g of electrolyte additive 2,6-dithia-1,3,5,7-tetraazatricyclo[3.3.1.13,7]decane was added thereto, with a mass percentage of 0.09%.

[0054] (2) Preparation of battery:

[0055] Mix 100 parts of graphite material, 1 part of conductive agent super-p, 1.5 parts of thickener sodium carboxymethyl cellulose, and 2.5 parts of styrene-butadiene rubber binder to form a uniform paste, and evenly coat the On the copper foil as the negative electrode current collector, dry it under vacuum at 80° C. for 24 hours to obtain the negative electrode sheet. Using LiNi 0.5 co 0.2 mn 0.3 o 2 As the positive active material, 100 parts of LiNi 0.5 co 0.2 mn 0.3 o 2 Mix with 2 parts of carbon nanotubes, 1 part of conductive agent super-p, and 2 parts of polyvinylidene fluoride to form a uniform paste, and...

Embodiment 2

[0058] The electrolyte was prepared in the same manner as in Example 1, except that the electrolyte additive was 6 g of 2,6-dithia-1,3,5,7-tetraazatricyclo[3.3.1.13,7]decane Alkanes, mass percent 2.5%. The battery preparation and formation process were the same as in Example 1, and a soft pack battery S2 was prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com