Solvent for electrolyte and application of solvent in high-voltage electrolyte of lithium ion battery

A lithium-ion battery and electrolyte technology, which is applied in the application field of solvent for electrolyte and high-voltage electrolyte of lithium-ion battery, to achieve the effect of inhibiting decomposition, good wettability and low viscosity, and improving high-temperature storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

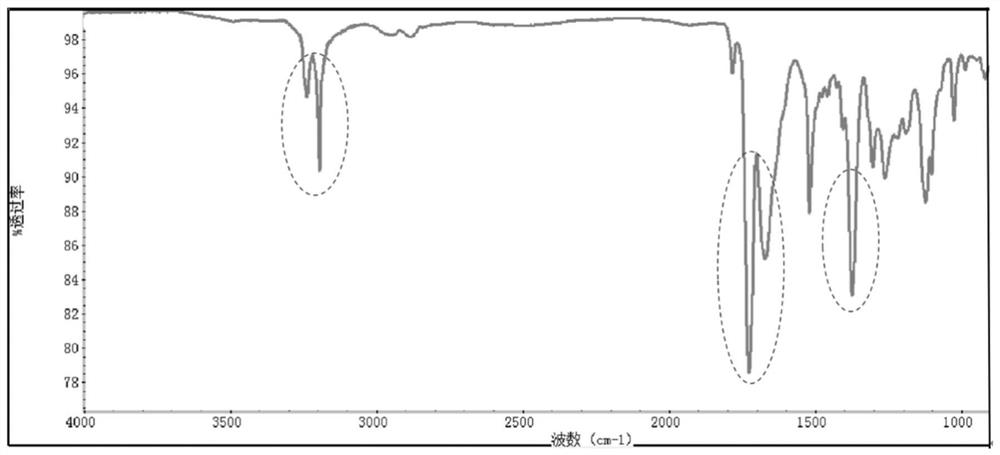

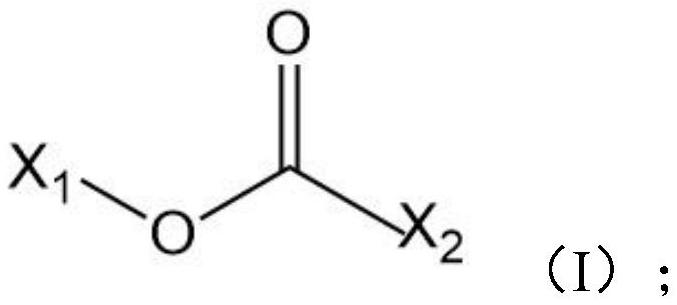

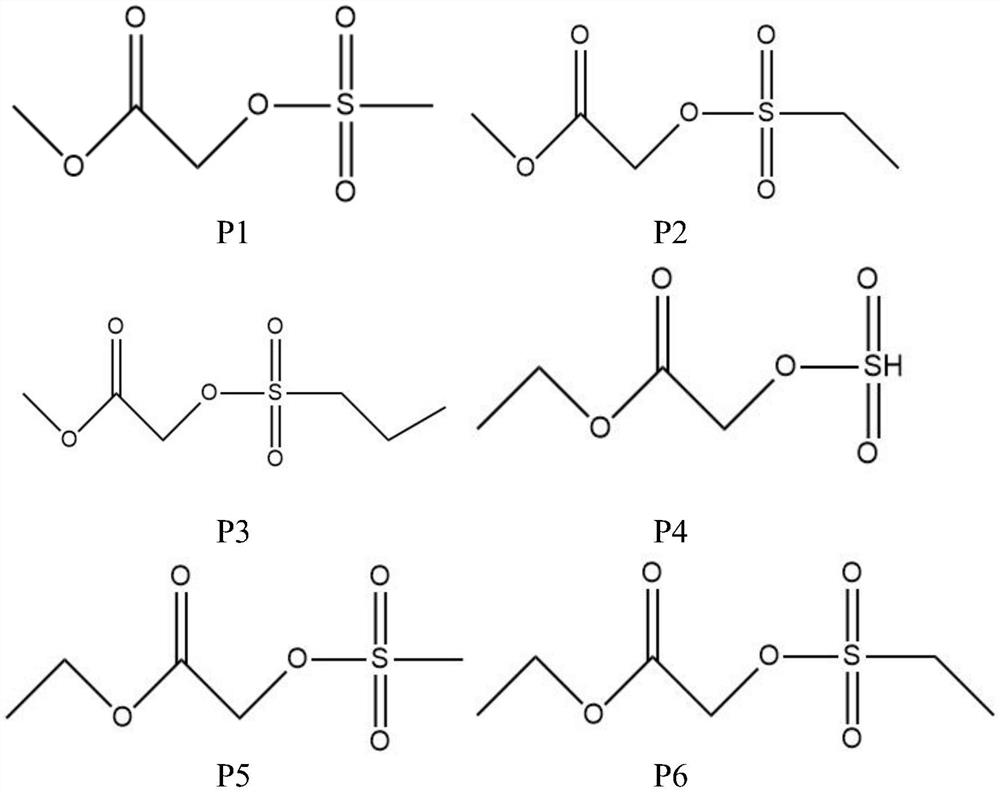

[0053] This embodiment provides a solvent for electrolyte, its structural formula is as follows:

[0054]

[0055] The preparation method of the solvent for the electrolyte provided in this example is: put sodium methanesulfinate into a round bottom flask filled with solvent and stir evenly, then slowly add ethyl bromoacetate (CAS: 105-36-2 ), stirring at 30°C-60°C for 12h-16h, the stirring speed is 200-800r / min, after washing and extraction, column chromatography and other treatments, the solvent for electrolyte shown in P1 is obtained, and the synthesis reaction is as follows:

[0056]

Embodiment 2

[0058] This embodiment provides a solvent for electrolyte, its structural formula is as follows:

[0059]

[0060] The preparation method of the solvent for electrolyte provided in this example is: put sodium benzene sulfinate into a round bottom flask filled with solvent and stir evenly, then slowly add ethyl chloroacetate (CAS: 105-39-5 )

[0061] Stir at 30°C-70°C for 12h-16h, the stirring speed is 200-900r / min, and after washing and extraction, column chromatography and other treatments, the solvent for electrolyte shown in P15 is obtained. The synthesis reaction is as follows:

[0062]

Embodiment 3

[0064] This embodiment provides a method for preparing a lithium-ion battery, wherein the positive electrode active material is a high-voltage lithium cobaltate material from Tianjin Bamo Technology, and the negative electrode is an artificial graphite material from Jiangxi Zichen. The specific steps are as follows:

[0065] (1) Positive electrode preparation steps: Weigh 3% polyvinylidene fluoride (PVDF), 2% conductive agent superP and 95% lithium cobaltate (LiCoO 2 ), sequentially added to N-methylpyrrolidone (NMP), fully stirred and mixed evenly, the slurry was coated on the aluminum foil current collector, dried, cold pressed, and punched to obtain the positive electrode sheet;

[0066] (2) Negative electrode preparation steps: Weigh 2% sodium carboxymethylcellulose (CMC), 3% styrene-butadiene rubber (SBR) and 94% graphite in mass percentage, add them to deionized water in turn, stir and mix well , coating the slurry on the copper foil current collector, drying, cold press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com