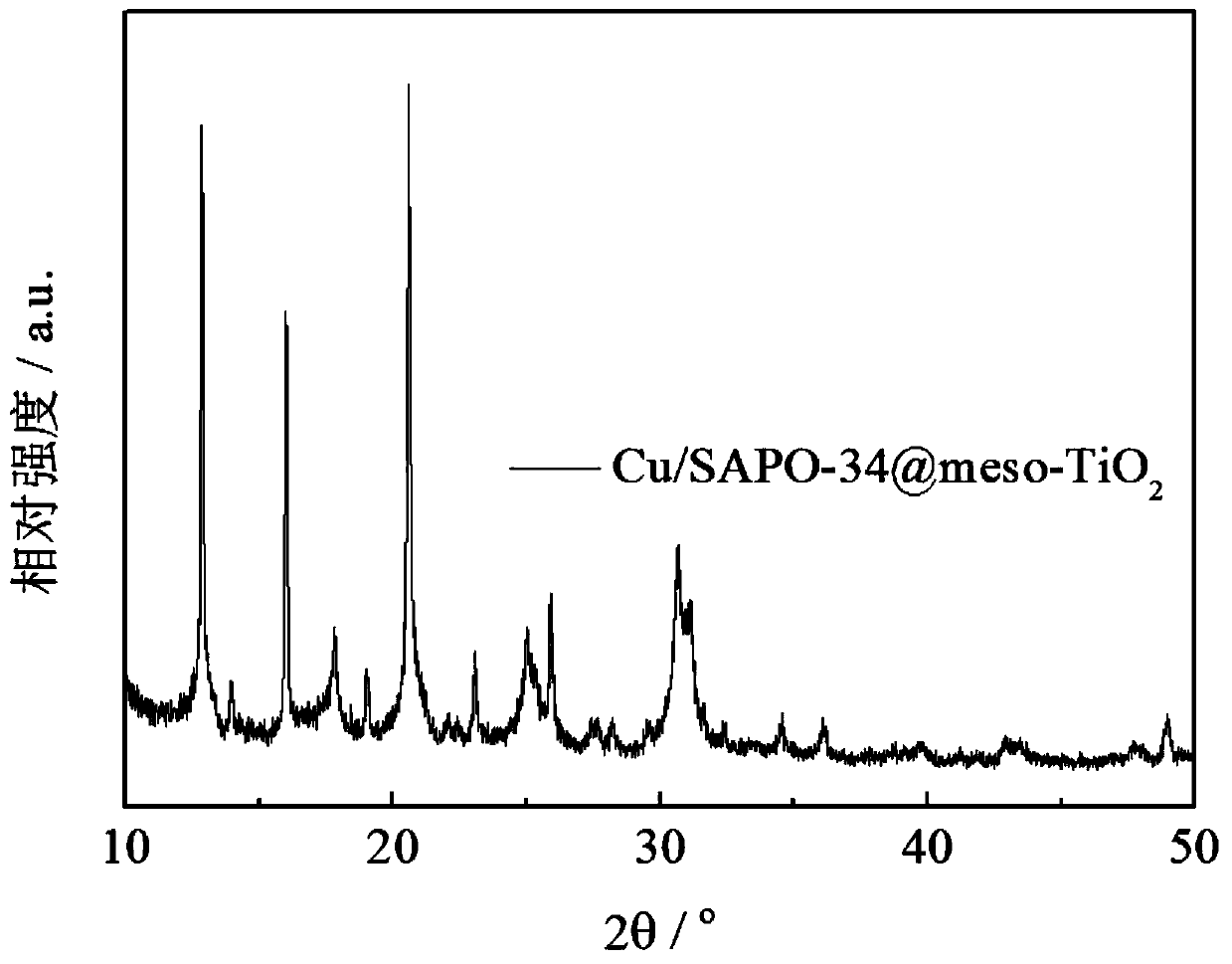

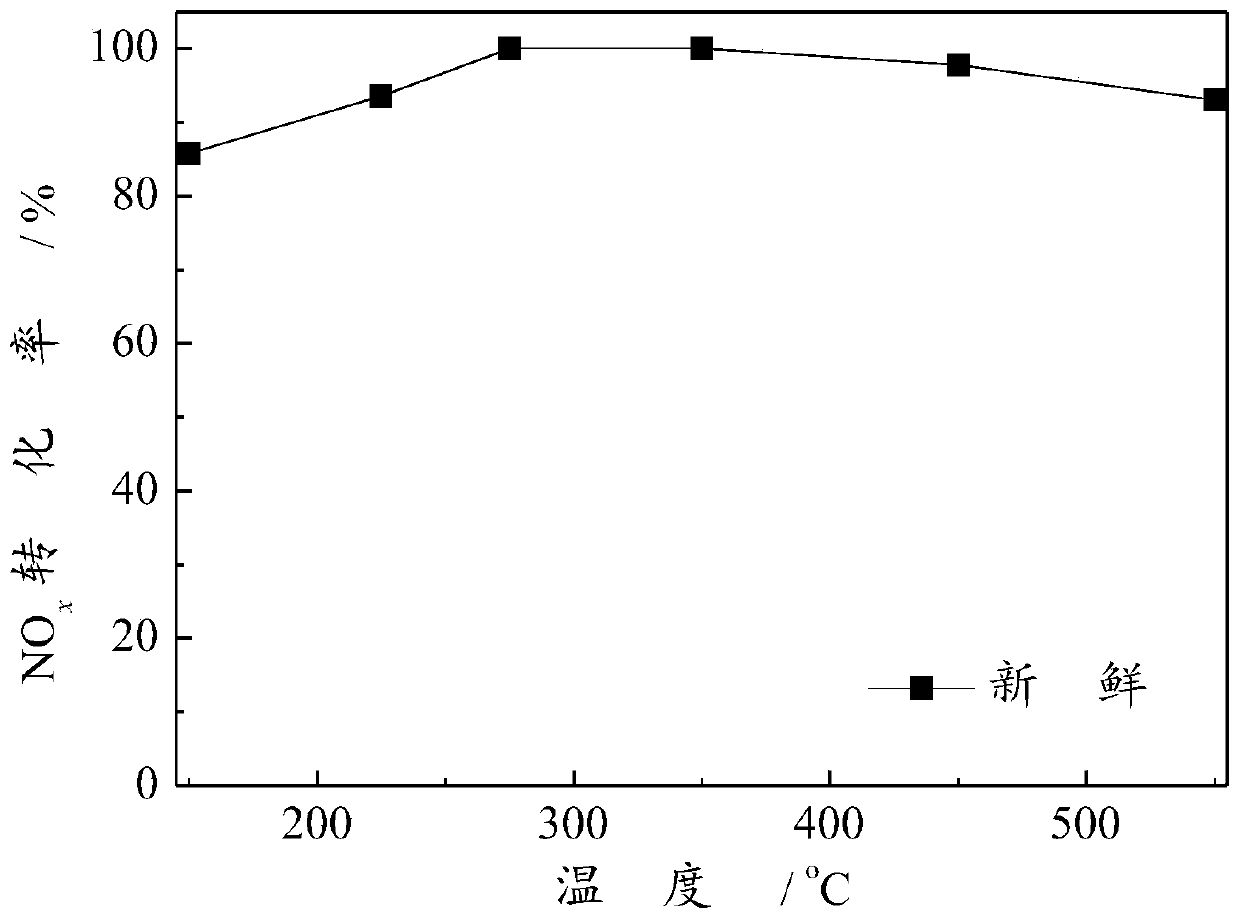

Cu/SAPO-34@meso-TiO2 catalytic material with core-shell structure, and preparation method and application thereof

A technology of SAPO-34 and catalytic materials, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve problems affecting the service life of new Cu molecular sieve catalysts, material deactivation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) First, H-SAPO-34 is added to the solution mass fraction of 25% NH 4 NO 3 solution and mixed evenly, the mass ratio of solid to liquid is 1:8, ion exchange at 80°C for 2h under high-speed magnetic stirring. Then the mixture was washed with deionized water until neutral, and dried at 100 °C for 12 h. Repeat the above process for the second ion exchange to obtain NH 4+ - SAPO-34 carrier material. Then, the NH 4+- Add SAPO-34 to a copper acetate solution with a mass fraction of 0.5% and mix evenly. The mass ratio of solid to liquid is 1:8, and perform ion exchange at 60°C for 4 hours under high-speed magnetic stirring. Then the mixture was washed with deionized water until neutral, dried at 100°C for 12h, and then calcined at 550°C for 4h to obtain Cu / SAPO-34 molecular sieve by liquid phase ion exchange method. P in the obtained Cu / SAPO-34 molecular sieve 2 o 5 、Al 2 o 3 , SiO 2 The mass ratio is 25:21:4, and the Cu content is 1% of the total mass of Cu / SAPO-3...

Embodiment 2

[0028] (1) First, H-SAPO-34 is added to the solution mass fraction of 25% NH 4 NO 3 solution and mixed evenly, the mass ratio of solid to liquid is 1:8, ion exchange at 80°C for 2h under high-speed magnetic stirring. Then the mixture was washed with deionized water until neutral, and dried at 100 °C for 12 h. Repeat the above process for the second ion exchange to obtain NH 4+ - SAPO-34 carrier material. Then, the NH 4+ -Add SAPO-34 into copper acetate solution with a mass fraction of 2% and mix evenly. The mass ratio of solid to liquid is 1:8, and perform ion exchange at 60°C for 4 hours under high-speed magnetic stirring. Then the mixture was washed with deionized water until neutral, dried at 100°C for 12h, and then calcined at 550°C for 4h to obtain Cu / SAPO-34 molecular sieve by liquid phase ion exchange method. P in the obtained Cu / SAPO-34 molecular sieve 2 o 5 、Al 2 o 3 , SiO 2 The mass ratio is 25:21:4, and the Cu content is 5% of the total mass of Cu / SAPO-34 ...

Embodiment 3

[0032] (1) The Cu / SAPO-34 molecular sieve prepared in Example 2 is added to the mixed solution of tetrahydrofuran and dimethylformamide, the volume ratio of tetrahydrofuran and dimethylformamide is 6:1, Cu / SAPO-34 molecular sieve and The solid-to-liquid mass ratio of the mixed solution was 1:500, and ultrasonically oscillated for 2 hours to obtain a suspension. Subsequently, the tetrahydrofuran solution dissolved with tetrabutyl titanate, silica gel and tungstic acid was added dropwise into the above-mentioned suspension under stirring, wherein the total volume of the three substances of tetrabutyl titanate, silica gel and tungstic acid was equal to The volume ratio of tetrahydrofuran is 1:10, the mass ratio of tetrabutyl titanate, silica gel and tungstic acid is 3.6:0.3:0.1, and the mass ratio of tetrabutyl titanate and Cu / SAPO-34 molecular sieve is 1:125, step by step A precipitate formed. After the precipitation was complete, stirring was continued for 2 h, and H 2 Mixtur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com