Heat-insulating composite material

A technology of composite materials and endothermic fillers, applied in electronic equipment, applications, electrochemical generators, etc., can solve the problems of hard texture, high price, hidden safety hazards, etc. damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

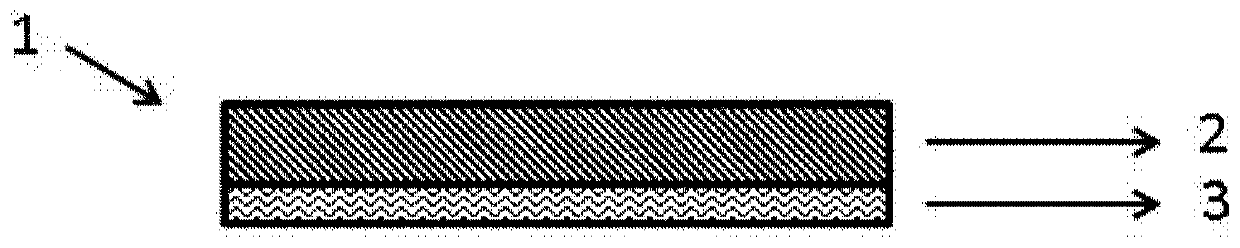

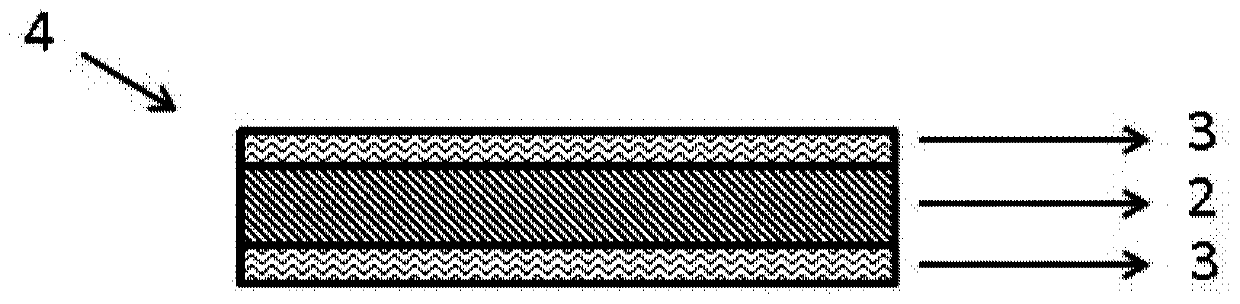

Image

Examples

Embodiment

[0099] In the present invention, unless otherwise indicated, the reagents used were all commercially available products, which were directly used without further purification treatment. In addition, the "parts" mentioned are "parts by weight".

[0100] testing method

[0101] Thermal insulation test

[0102] Thermal insulation tests were performed on the thermal insulation composite materials prepared in the following Examples and Comparative Examples. Specifically, a heating plate with a length of 1.75 inches and a width of 1.75 inches was fixed vertically relative to a horizontal plane, and its temperature was raised to a constant temperature of 600°C. The thermal insulation composite materials prepared in the following examples and comparative examples were respectively used as sample sheets (the length is 1.75 inches, the width is 1.75 inches, and the specific thickness can be calculated from the data in Table 2 below). The sample sheet was positioned vertically wit...

preparation example 1

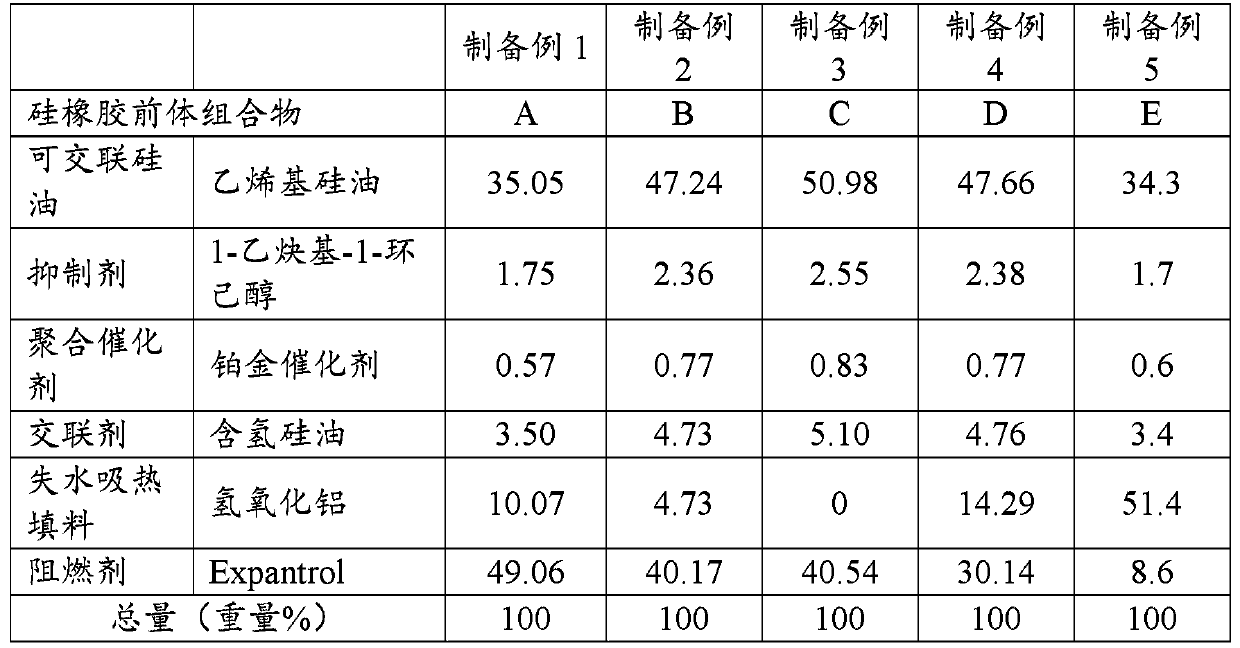

[0103] Preparation example 1 (preparation of silicone rubber precursor composition A)

[0104] Vinyl silicone oil (produced by AB Andisil Company; viscosity of 5000 cSt) as crosslinkable silicone oil, hydrogen-containing silicone oil (by AB Andisil Company) as crosslinking agent, Expantrol (which contains 73% by weight) as flame retardant sodium silicate, an aqueous solution of 17% by weight zinc borate and 10% by weight water), 1-ethynyl-1-cyclohexanol (produced by Macklin Corporation) as an inhibitor, platinum catalyst (produced by Herasus Corporation) as a polymerization catalyst ) and the aluminum hydroxide as the dehydration endothermic filler are added in the stirring tank according to the proportioning shown in the following table 1 (the total weight of the obtained silicone rubber precursor composition is 100% by weight), and then The stirring tank was placed in a star mixer (speed mixer), and mixed and stirred at a speed of 1900 rpm for 3 minutes, thereby obtaining a ...

preparation example 2-5

[0105] Preparation Example 2-5 (Preparation of Silicone Rubber Precursor Composition B-E)

[0106] Silicone rubber precursor compositions B-E were prepared in a manner similar to the method described in Preparation Example 1, except that the ratio of each component was changed according to the ratio shown in Table 1 below, so as to obtain a gel-like viscous Silicone rubber precursor compositions of matter B-E.

[0107] The proportioning of the silicone rubber precursor composition A-E in the preparation example 1-5 of table 1 (with the total weight of the silicone rubber precursor composition obtained being 100% by weight)

[0108]

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com