Denitrification and dephosphorization filler for sewage and preparation method thereof

A technology for denitrification and dephosphorization, sewage, applied in water/sewage treatment, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problem of inability to absorb and enrich nitrate, lack of denitrification and denitrification, and affect treatment rate, etc. problems, to achieve the effect of improving phosphorus removal effect, improving nitrogen removal effect, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

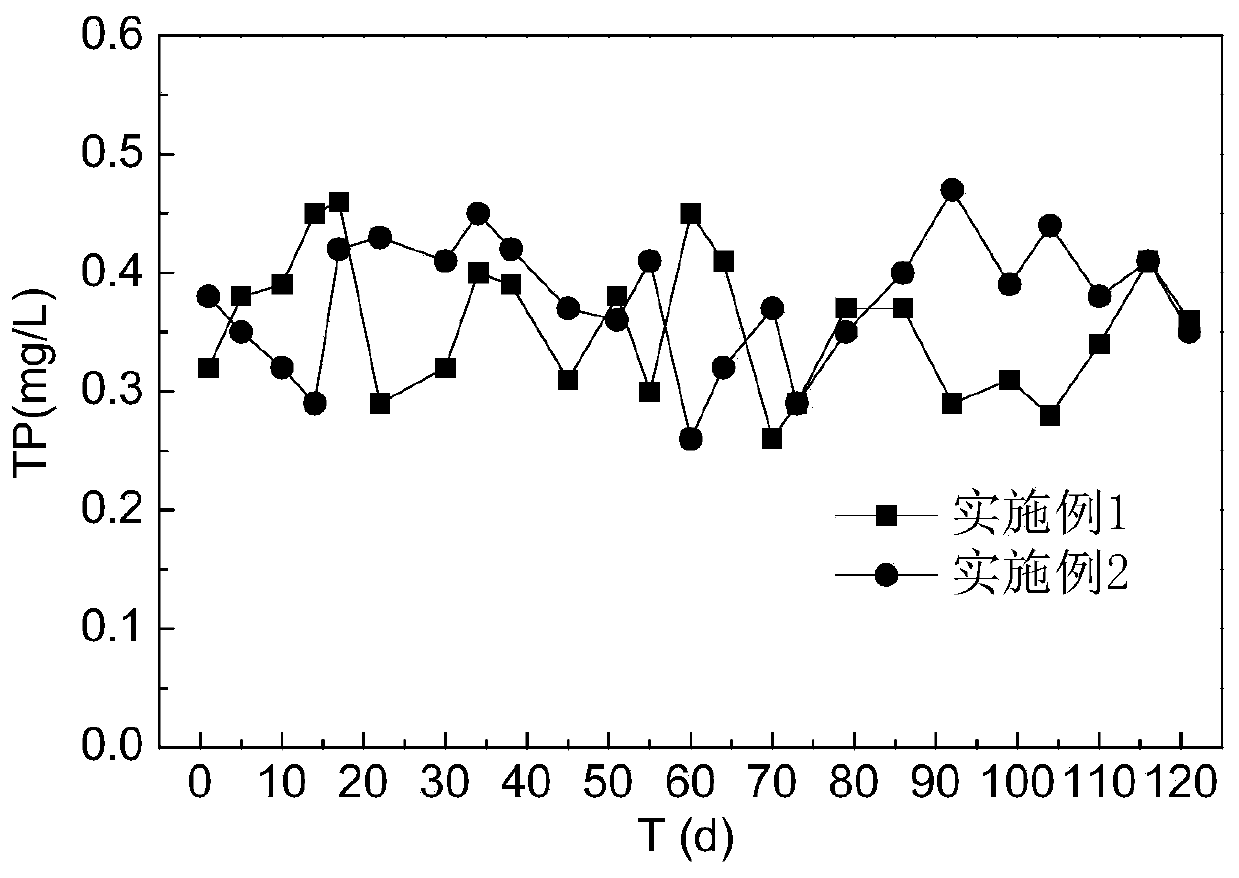

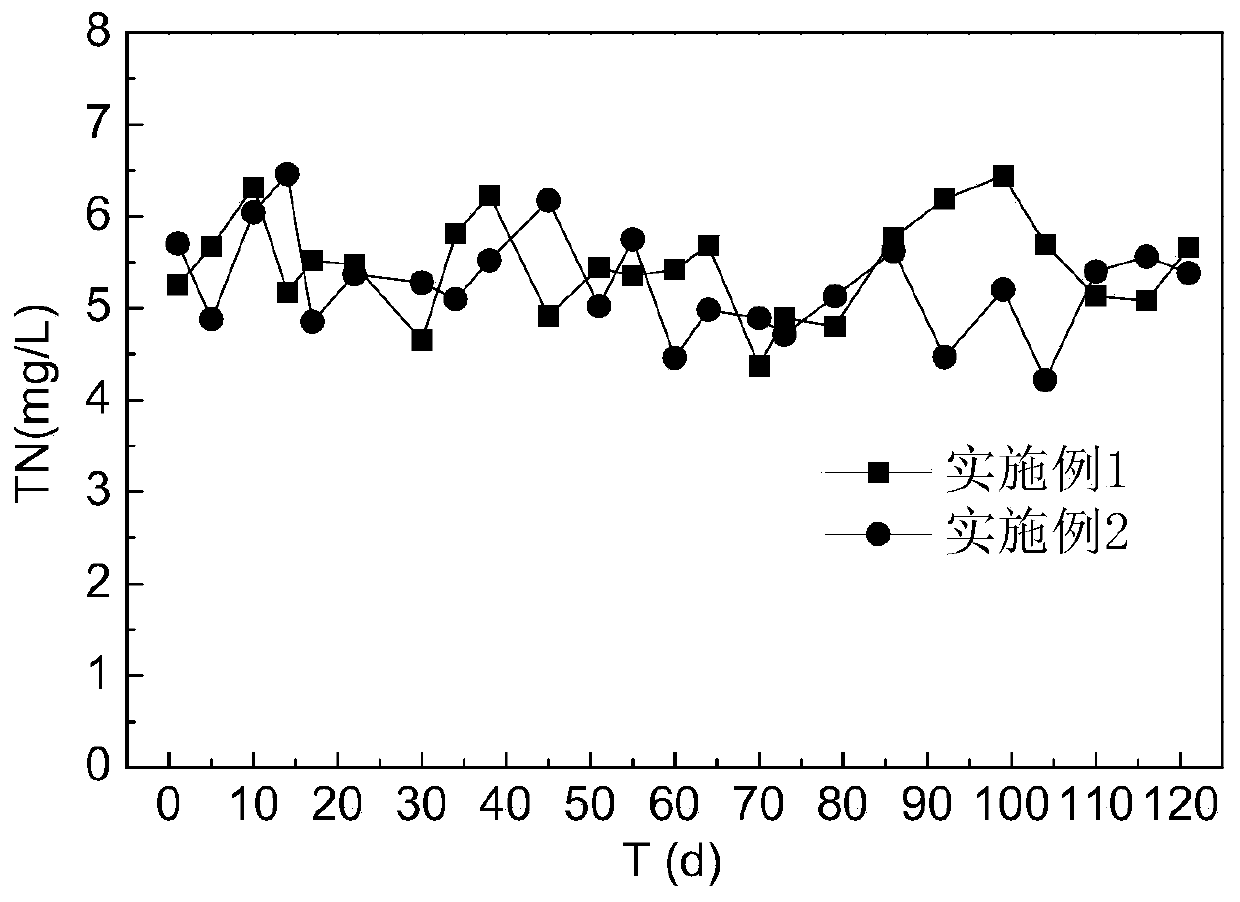

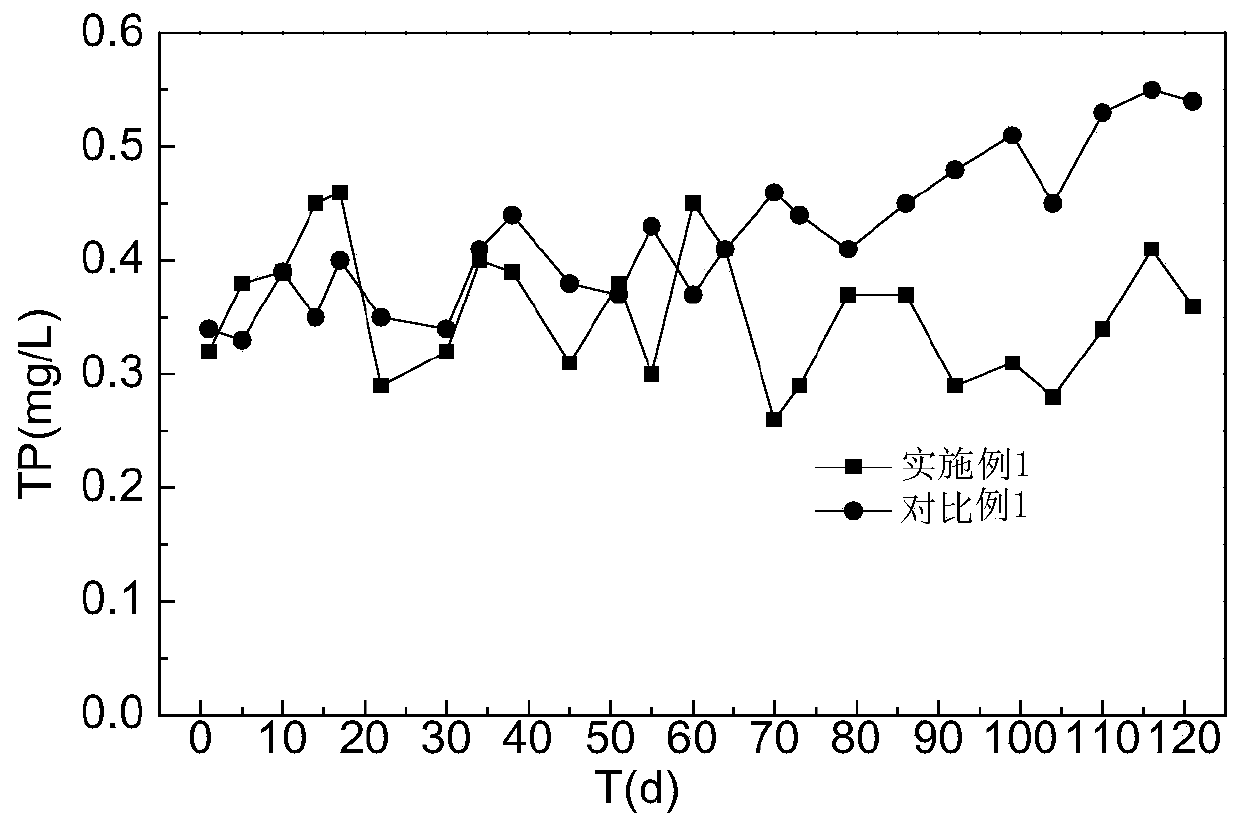

Embodiment 1

[0031] Take 40 parts of wheat straw, wash them with distilled water, soak them in 1.5mol / L ferric chloride solution for 12 hours, take them out and put them in a constant temperature drying oven to dry at 80°C, then put them in a muffle furnace and roast them under anaerobic conditions for 3 hours , the calcination temperature is 400° C. and carbonized for 3 hours, taken out and pulverized with a pulverizer, and obtained modified biochar powder with a particle size of less than 50 meshes with a sieve. Take 30 parts of wheat straw, wash it with distilled water, take it out and put it in a constant temperature drying oven to dry at 80°C, take it out and grind it with a pulverizer, and use a sieve to obtain solid carbon source powder with a particle size of less than 100 mesh. Take 40 parts of iron powder, 30 parts of carbon powder and 7 parts of bentonite with particle diameters less than 100 mesh, mix with 20 parts of cement and the above-mentioned modified biochar and solid car...

Embodiment 2

[0033] Take 40 parts of wheat straw, wash them with distilled water, soak them in 1.5mol / L ferric chloride solution for 18 hours, take them out and dry them in a constant temperature drying oven at 80°C, then put them in a muffle furnace and roast them under anaerobic conditions for 3 hours , the calcination temperature is 400°C and carbonized for 3.5 hours, take it out and pulverize it with a pulverizer, and use a sieve to obtain modified biochar powder with a particle size of less than 50 mesh. Take 30 parts of wheat straw, wash it with distilled water, take it out and put it in a constant temperature drying oven to dry at 80°C, take it out and grind it with a pulverizer, and use a sieve to obtain solid carbon source powder with a particle size of less than 100 mesh. Take 40 parts of iron powder, 30 parts of carbon powder and 7 parts of bentonite with particle diameters less than 100 mesh, mix with 25 parts of cement, the above-mentioned modified biochar and solid carbon sour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com