Method and apparatus for rapidly degrading azo wastewater

A rapid degradation and azo technology, applied in chemical instruments and methods, textile industry wastewater treatment, water pollutants, etc., can solve the problem of low treatment efficiency, achieve good effect, convenient operation, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

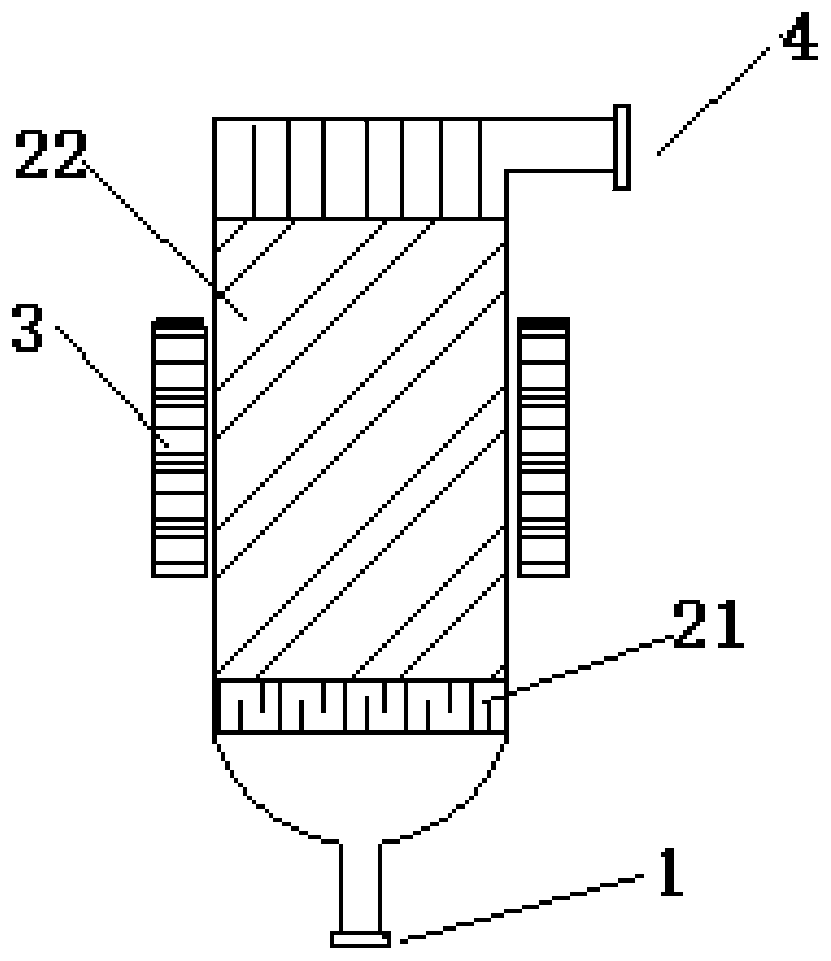

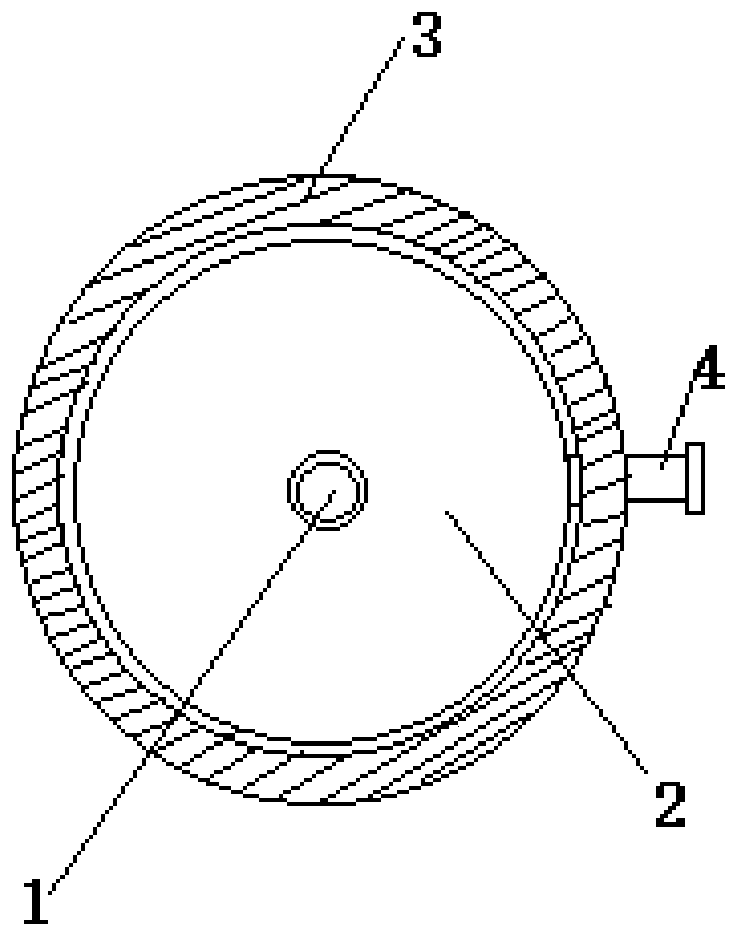

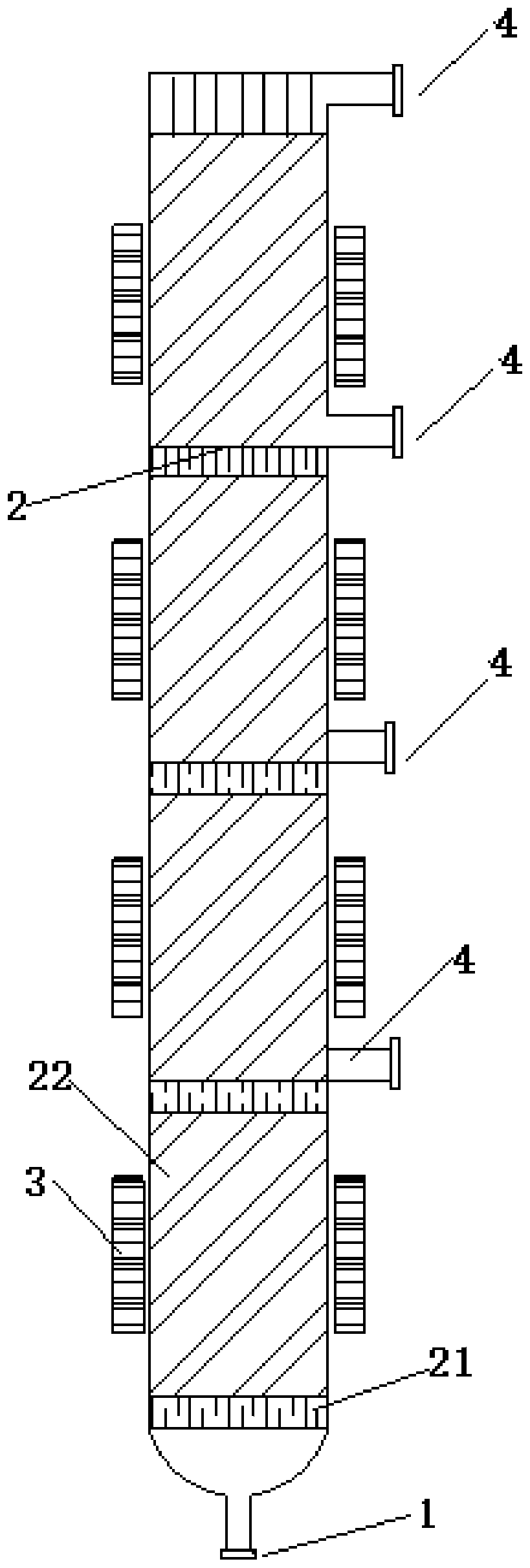

[0047] see Figure 1-4 , the present invention provides a technical solution:

[0048]A reactor device for rapidly degrading azo wastewater, comprising a water inlet 1, a reactor 2, a magnetic field generator 3 and a water outlet 4; the reactor 2 includes an isolation layer 21 and a reaction medium filling area 22 sequentially from the top; the The water inlet 1 communicates with the isolation layer 21, the end of the reaction medium filling area 22 communicates with the water outlet 4, and the outer wall of the reactor 2 has a magnetic field generator 3.

[0049] Specifically, the reaction medium filling area 22 is filled with a reaction medium system, and the reaction medium system includes zero-valent iron and a filling medium, and the two are uniformly mixed, and the filling medium is activated carbon, quartz sand, zeolite, montmorillonite One or more; the mass ratio of zero-valent iron to filling medium in the reaction medium system is 1-3:18-20.

[0050] Specifically, ...

Embodiment 2

[0058] A method for rapidly degrading azo wastewater, comprising the steps of:

[0059] Step 1: Adjust the pH value of the water body of the azo dye to be treated to 3.0-7.0, and no adjustment is required if the pH value of the water body is satisfactory;

[0060] Step 2: Pass the water body of azo dye into the equipment of Example 1 at a uniform speed, that is, react in a magnetic reaction medium system containing zero-valent iron;

[0061] Step 3: Adjust the pH of the water body to neutral and discharge it;

[0062] The reaction medium system includes zero-valent iron and a filling medium, which are uniformly mixed, and the filling medium is one or more of activated carbon, quartz sand, zeolite, and montmorillonite.

[0063] Under the action of the magnetic field, it can promote the reaction of zero-valent iron in the reaction medium system. The magnetic field promotes the corrosion of zero-valent iron, because the zero-valent iron is magnetized in the external magnetic fi...

Embodiment 3

[0071] A method for rapidly degrading reactive brilliant red X-3B, establishing a reactor device for rapidly degrading azo wastewater, mixing zero-valent iron with quartz sand in a certain proportion, filling it in a column, and entering water into the water inlet at the lower end, Before the experiment starts, first turn on the peristaltic pump (preheat about 30 minutes in advance), adjust the speed to 1r / min as needed, and then configure 1g / L Reactive Brilliant Red X-3B reaction solution and dilute it to Different concentrations (10mg / L, 5mg / L, 3mg / L), and then configure buffer solutions with different pH (4, 5, 6), and finally, adjust the pH with 0.1mol / L NaOH or HCl solution.

[0072] Such as Figure 5 For this example, the effect of pH on the kinetics of removal of reactive brilliant red X-3B by magnetic field-strengthened zero-valent iron was studied, and the pH was 4-6. Figure 5 a is Reactive Brilliant Red X-3B with a concentration of 3mg / L, [Zerovalent Iron (abbrevia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com