Environment-friendly odorless prefabricated plastic runway coiled material and preparation method thereof

A plastic track and prefabricated technology, applied in the field of plastic track, can solve the problems of high equipment and production costs, poor sports experience, strong sulfur smell, etc., and achieve the effect of low production investment cost, no need for vulcanization, and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

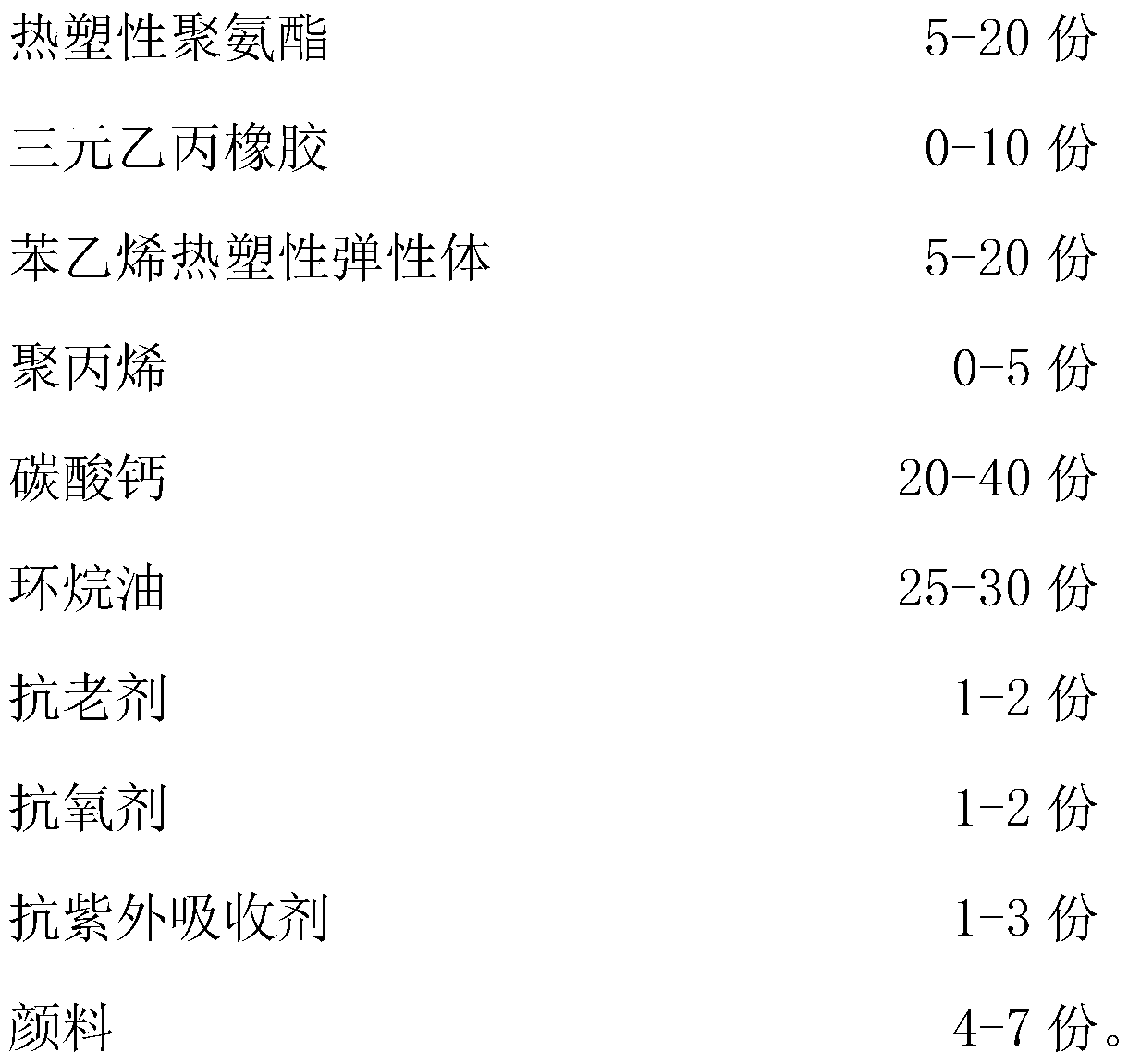

[0019] An environmentally friendly and odor-free prefabricated plastic runway coil, the coil is composed of the following components by weight:

[0020]

[0021] Wherein, in the present embodiment, the preparation method of the coiled material is as follows:

[0022] Step S1: Accurately weigh thermoplastic polyurethane, EPDM rubber, styrene thermoplastic elastomer, polypropylene, calcium carbonate, naphthenic oil, anti-aging agent, antioxidant, anti-ultraviolet absorber, and pigment according to the weight ratio , to obtain the component raw materials;

[0023] Step S2: Add the component raw materials to the pulverizer through the automatic feeder and mix them uniformly to obtain crushed materials;

[0024] Step S3: Add the crushed material to the extruder, heat and extrude to obtain a sheet;

[0025] Step S4: The sheet is molded by the die roller, and the top and bottom layers of the runway surface and the texture of the bottom layer appear up and down to obtain a semi-f...

Embodiment 2

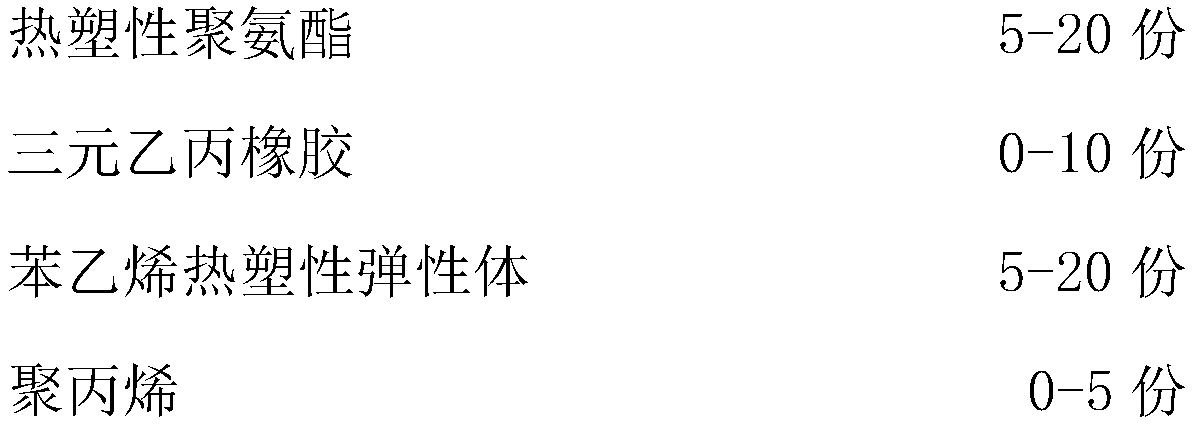

[0031] An environmentally friendly and odor-free prefabricated plastic runway coil, the coil is composed of the following components by weight:

[0032]

[0033] Wherein, in the present embodiment, the preparation method of the coiled material is as follows:

[0034] Step S1: Accurately weigh thermoplastic polyurethane, EPDM rubber, styrene thermoplastic elastomer, polypropylene, calcium carbonate, naphthenic oil, anti-aging agent, antioxidant, anti-ultraviolet absorber, and pigment according to the weight ratio , to obtain the component raw materials;

[0035] Step S2: Add the component raw materials to the pulverizer through the automatic feeder and mix them uniformly to obtain crushed materials;

[0036] Step S3: Add the crushed material to the extruder, heat and extrude to obtain a sheet;

[0037] Step S4: The sheet is molded by the die roller, and the top and bottom layers of the runway surface and the texture of the bottom layer appear up and down to obtain a semi-f...

Embodiment 3

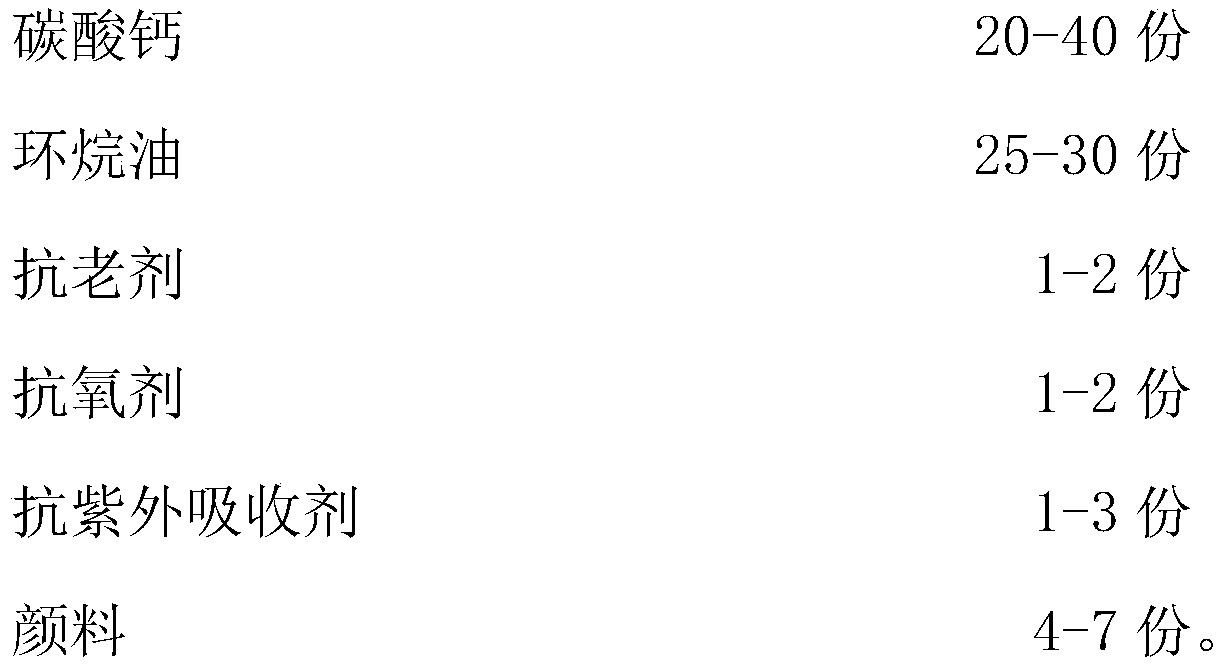

[0043] An environmentally friendly and odor-free prefabricated plastic runway coil, the coil is composed of the following components by weight:

[0044]

[0045] Wherein, in the present embodiment, the preparation method of the coiled material is as follows:

[0046] Step S1: Accurately weigh thermoplastic polyurethane, EPDM rubber, styrene thermoplastic elastomer, polypropylene, calcium carbonate, naphthenic oil, anti-aging agent, antioxidant, anti-ultraviolet absorber, and pigment according to the weight ratio , to obtain the component raw materials;

[0047] Step S2: Add the component raw materials to the pulverizer through the automatic feeder and mix them uniformly to obtain crushed materials;

[0048] Step S3: Add the crushed material to the extruder, heat and extrude to obtain a sheet;

[0049] Step S4: The sheet is molded by the die roller, and the top and bottom layers of the runway surface and the texture of the bottom layer appear up and down to obtain a semi-f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com