Method for producing medium-chain fatty acid from fermented liquor of livestock and poultry manure

A medium-chain fatty acid, livestock and poultry manure technology, applied in the field of medium-chain fatty acid production, to achieve the effect of reducing methanation and reducing metabolic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

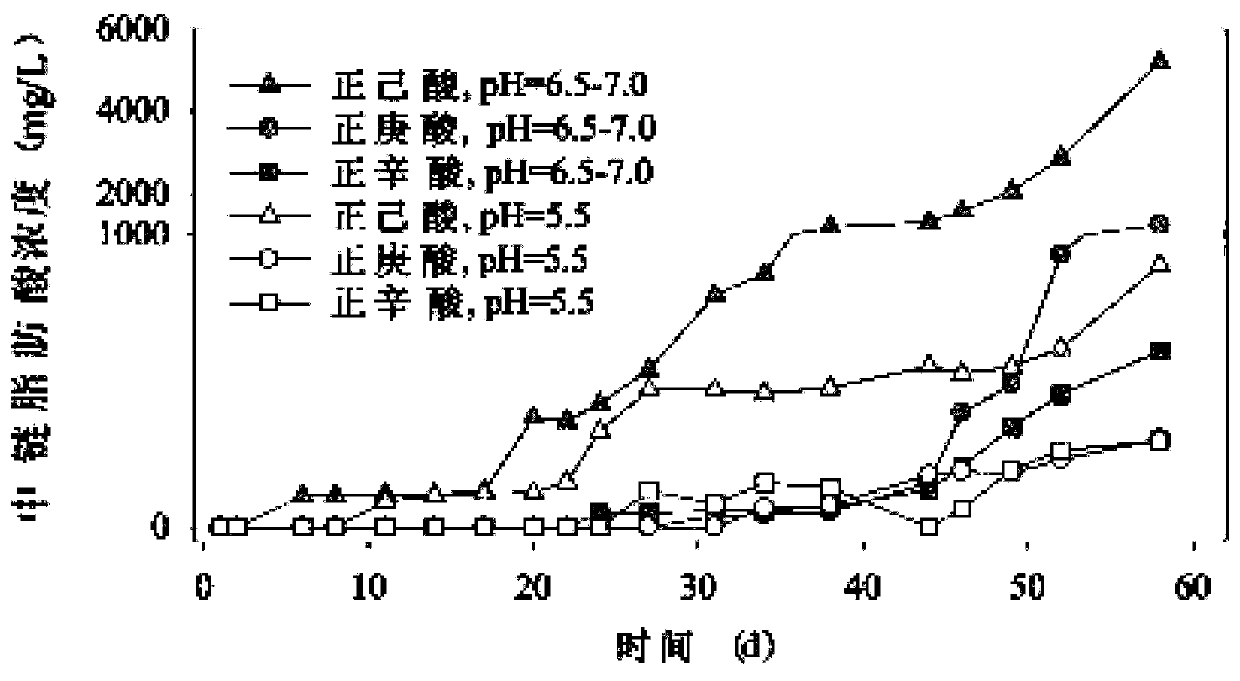

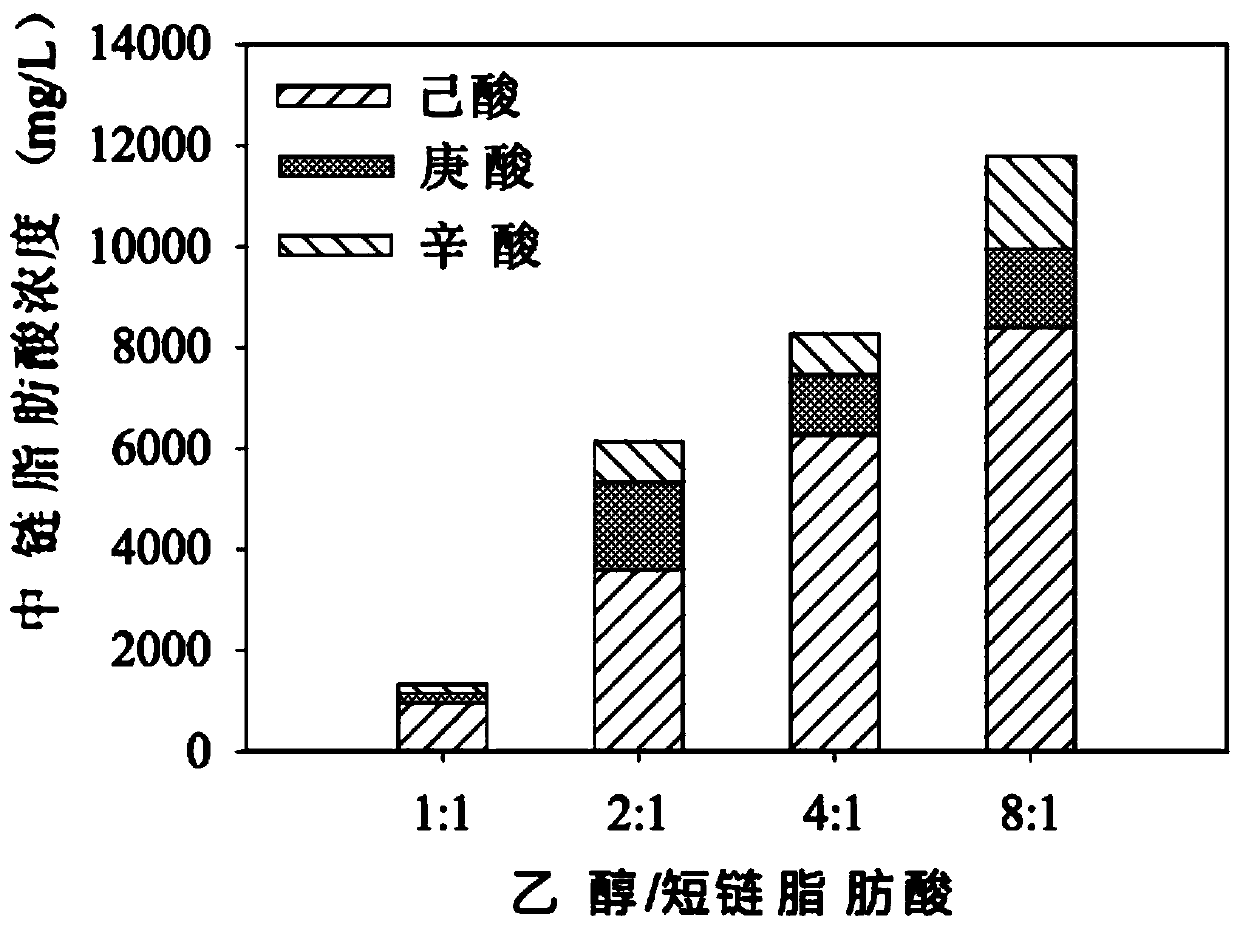

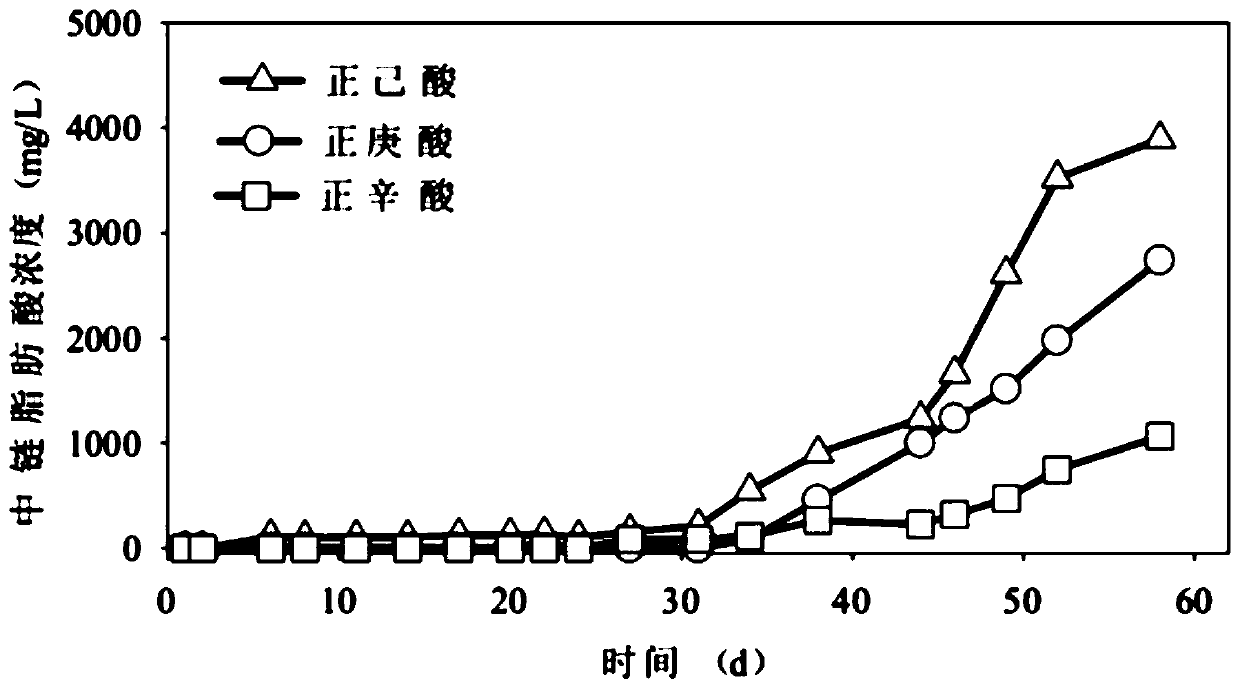

Image

Examples

Embodiment 1

[0018] The mixed short-chain fatty acid solution obtained from the fermentation of livestock and poultry manure contains complex components, which generally include acetic acid 2000-8000mg / L, propionic acid 500-3000mg / L, n-butyric acid 500-4000mg / L, isobutyric acid 300-2000mg / L, n-valeric acid 100-2000mg / L and isovaleric acid 100-2000mg / L.

[0019] This embodiment includes the following steps:

[0020] A. Heat-treat the inoculated sludge in advance; the pretreatment conditions for the inoculated sludge are 70°C water bath for 3 hours, 85°C water bath for 3 hours and 90°C water bath for 3 hours.

[0021] B. Fermentation substrate: first add 150mL of inoculated sludge in a 2000mL anaerobic fermentation bottle (effective volume 1500mL), then add the mixed short-chain fatty acid solution (C2~C5) obtained by the fermentation of livestock and poultry manure again, and measure the short-chain fatty acids in the fermentation system The initial content of chain fatty acids is about (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com