Blast furnace hot blast stove coal gas system high-efficiency coal gas dispelling method

A gas system and hot blast stove technology, applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems that affect the progress of maintenance work, prolong the time of blast furnace shutdown, and delay the maintenance period, so as to increase the maintenance work time and shorten the blowing time. Sweep time and ensure the effect of maintenance period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A method for efficiently driving away gas from a gas system of a blast furnace hot blast stove. Its process steps are:

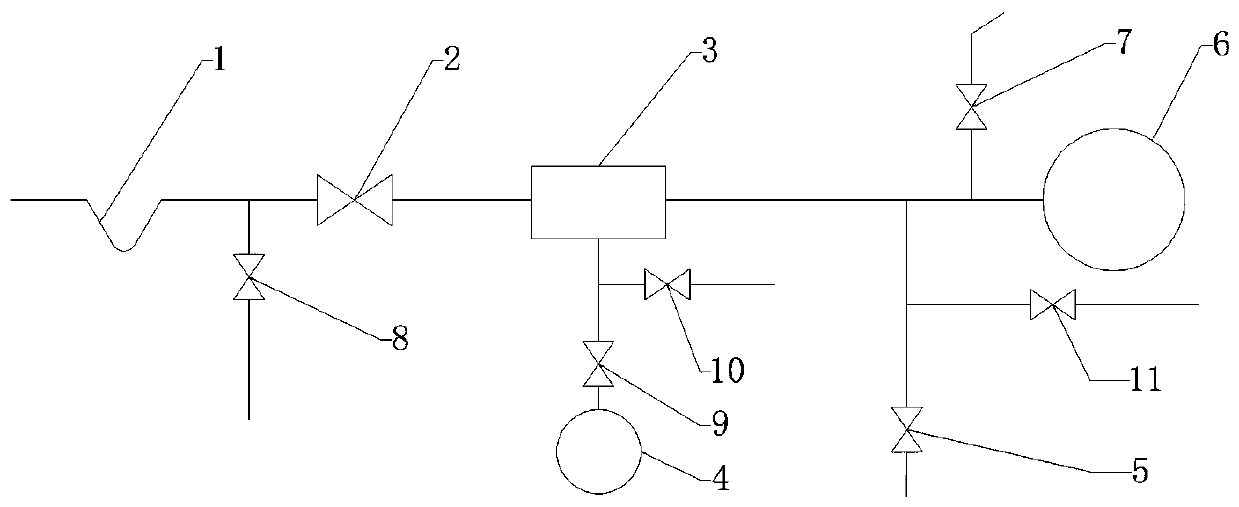

[0018] In the first step, a tee pipe is connected to the outlet valve of the gas preheater before the blast furnace shutdown, one end is connected to the raw gas drainer 4 through the gate valve 2 9, and one end is connected to the nitrogen hose through the gate valve 3 10. At the same time, connect the nitrogen pipe interface at the coke oven gas blending valve 5 with the nitrogen pipe through the gate valve 411.

[0019] In the second step, after the blast furnace shutdown and the hot blast stove stop burning, fill the water seal 1 of the gas main pipe as required to ensure that there is overflow water in the high water seal; after opening the gas branch release valve 7 of the hot blast stove, water seal the gas main pipe Gate valve one 8 is opened at the place, feeds nitrogen gas 12, and the gas pipeline is purged.

[0020] In the third step, aft...

Embodiment

[0025] Currently in a steel company 3200m 3 The blast furnace hot blast stove is used for one year to drive the gas during maintenance, and the time from driving the gas to passing the test is shortened from the original 8 hours to 5 hours. It can be applied to gas systems similar to large, medium and small blast furnace hot blast stoves in the same industry. This technology only optimizes and applies the existing equipment on the gas pipeline without additional investment in other equipment. It is simple and efficient, and can indirectly increase the maintenance work time, ensure that the maintenance period is controllable, and eliminate the need for the blast furnace to resume production on time due to the long time to catch up with the gas. constraints. The above are only preferred embodiments of the present invention, and are not intended to limit the present invention. Any modifications, equivalent replacements, improvements, etc. within the principles of the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com