A kind of preparation method of single-phase carboride solid solution ceramic material

A ceramic material and boride technology, which is applied in the field of preparation of single-phase carbon boride solid solution ceramic materials, can solve the problems of low solid solubility of transition metal carbides and borides, and it is difficult to prepare transition metal carbon borides, etc. Strength and hardness improvement, effect of reducing sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0020] Specific embodiment 1: the boride is titanium boride, and the carbide is zirconium carbide

[0021] (1) Mix the titanium boride powder and the zirconium carbide powder according to the mass ratio of 85:15, and use a high-energy ball mill for ball milling. The ball milling conditions are: the ball-to-material ratio is 10:1, the ball milling time is 30h, and the rotating speed is 500r / min. Composite powder with uniform composition and fine particles;

[0022] (2) Put the composite powder in the mold and sinter in a hot-press furnace. The sintering conditions are as follows: the graphite heating body in the hot-press furnace is heated up to 2000°C at a rate of 20°C / min, kept for 1h and sintered under pressure. After the sintering is completed, the mold is cooled and demolded to obtain a single-phase carboride solid solution ceramic material (i).

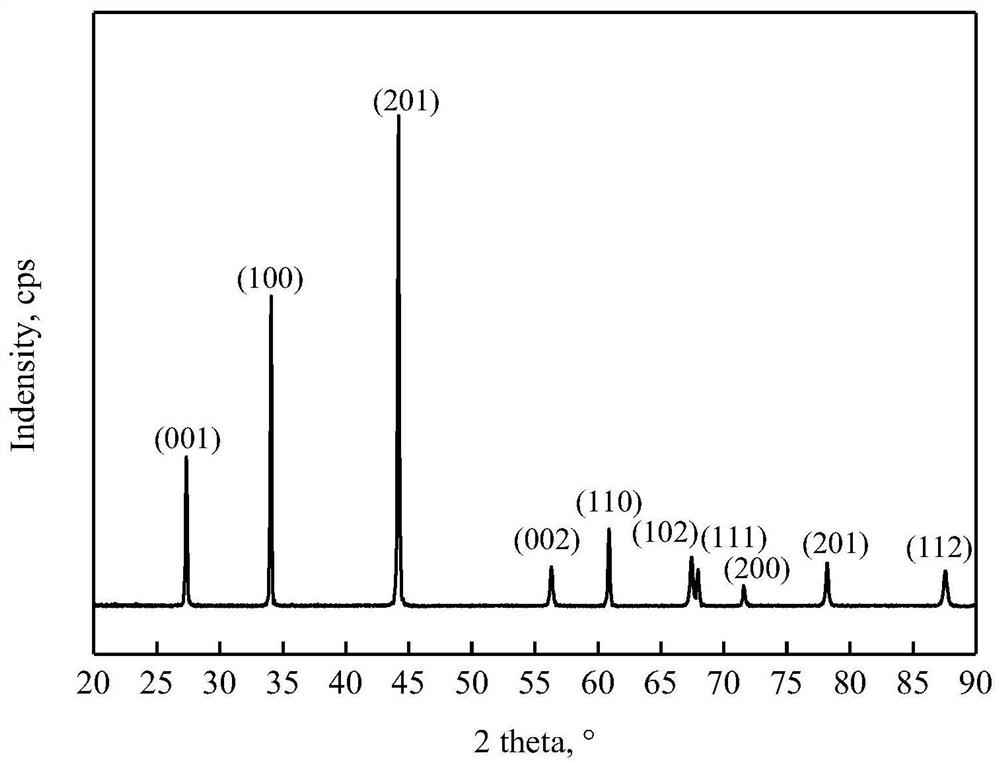

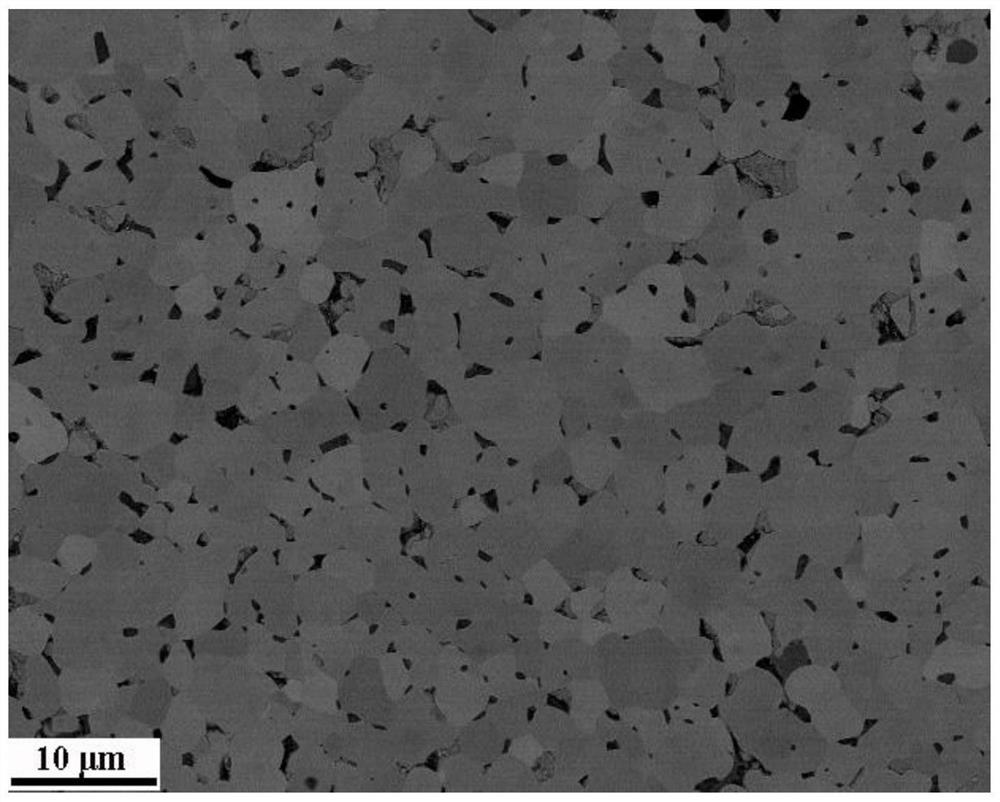

[0023] Carry out XRD test to single-phase carboride solid solution ceramic material (i), test result is as follows figure 1 s...

specific Embodiment approach 2

[0026] Specific embodiment 2: the boride is titanium boride, and the carbide is zirconium carbide

[0027] (1) Mix the titanium boride powder and the zirconium carbide powder according to the mass ratio of 90:10, and use a high-energy ball mill for ball milling. The ball milling conditions are: the ball-to-material ratio is 10:1, the ball milling time is 30h, and the speed is 500r / min. Composite powder with uniform composition and fine particles;

[0028] (2) Put the composite powder in the mold and sinter in a hot-press furnace. The sintering conditions are as follows: the graphite heating body in the hot-press furnace is heated up to 2000°C at a rate of 20°C / min, kept for 1h and sintered under pressure. After the sintering is completed, the mold is cooled and demolded to obtain a single-phase carboride solid solution ceramic material (ii).

[0029] The mechanical properties of the single-phase carboride solid solution ceramic material (ii) were characterized. The results sh...

specific Embodiment approach 3

[0030] Specific embodiment 3: the boride-containing compound is titanium boride, and the carbide-containing compound is zirconium carbide

[0031] (1) Mix titanium boride powder and zirconium carbide powder according to the mass ratio of 95:5, and use a high-energy ball mill for ball milling. The ball milling conditions are: ball-to-material ratio 10:1, ball milling time 30h, speed 500r / min, to obtain Composite powder with uniform composition and fine particles;

[0032] (2) Put the composite powder in the mold and sinter in a hot-press furnace. The sintering conditions are as follows: the graphite heating body in the hot-press furnace is heated up to 2000°C at a rate of 20°C / min, kept for 1h and sintered under pressure. After the sintering is completed, the mold is cooled and demolded to obtain a single-phase carboride solid solution ceramic material (iii).

[0033] The mechanical properties of the single-phase carboride solid solution ceramic material (iii) were characteriz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com