General chassis cell for synthesizing acetylcoenzyme A derived product and construction method and application of general chassis cell

A technology of acetyl coenzyme and derivative products, applied in the field of genetic engineering, can solve the problems such as cumbersome transformation process of recombinant bacteria, lack of versatility, time-consuming, etc., achieves great application potential, reduces the synthesis of acetic acid by-products, and has a wide range of applications. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Embodiment 1: the construction of universal chassis cell

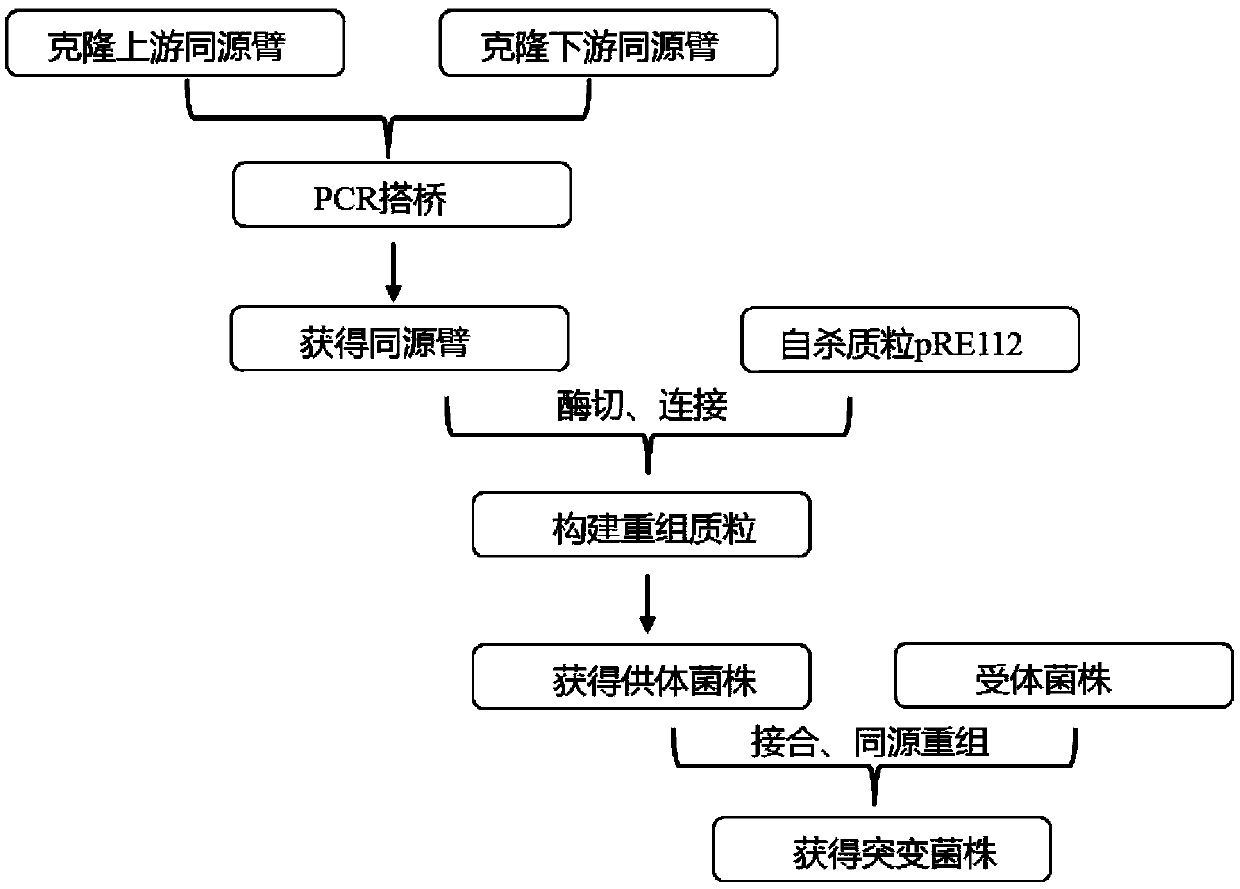

[0071] 1. Gene knockout

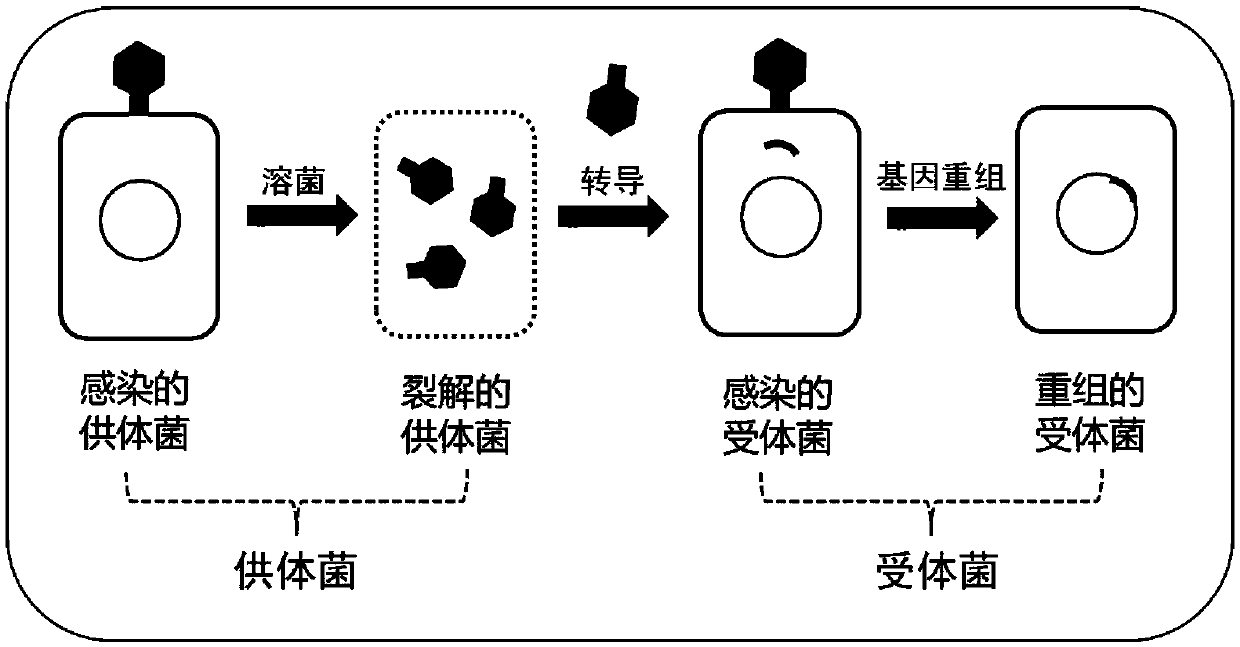

[0072] Using the P1 phage transduction method (principle such as figure 1 ) to knock out the global regulatory factor arcA and the acetate kinase gene ackA of Escherichia coli E. coli BL21 (DE3) genome respectively.

[0073] 1. The knockout method of the global regulatory factor arcA:

[0074] 1) Phage activation

[0075] Add 4ml of heated and melted 0.4% agar medium to a 10ml sterile EP tube, add 400 μL of overnight cultured donor strain JW4364 (the donor strain is derived from the Keio Collection library, which can be purchased commercially, and the KeioCollection library construction method is as follows: Baba T, et al. Construction of Escherichia coli K-12in-frame, single-gene knockout mutants: the Keio collection. Molecular Systems Biology 2006, 2(1): 1-11), add 10 μL of stored phage stock solution, and mix the solution Then pour it on the LB plate without anti-antibody, and cu...

Embodiment 2

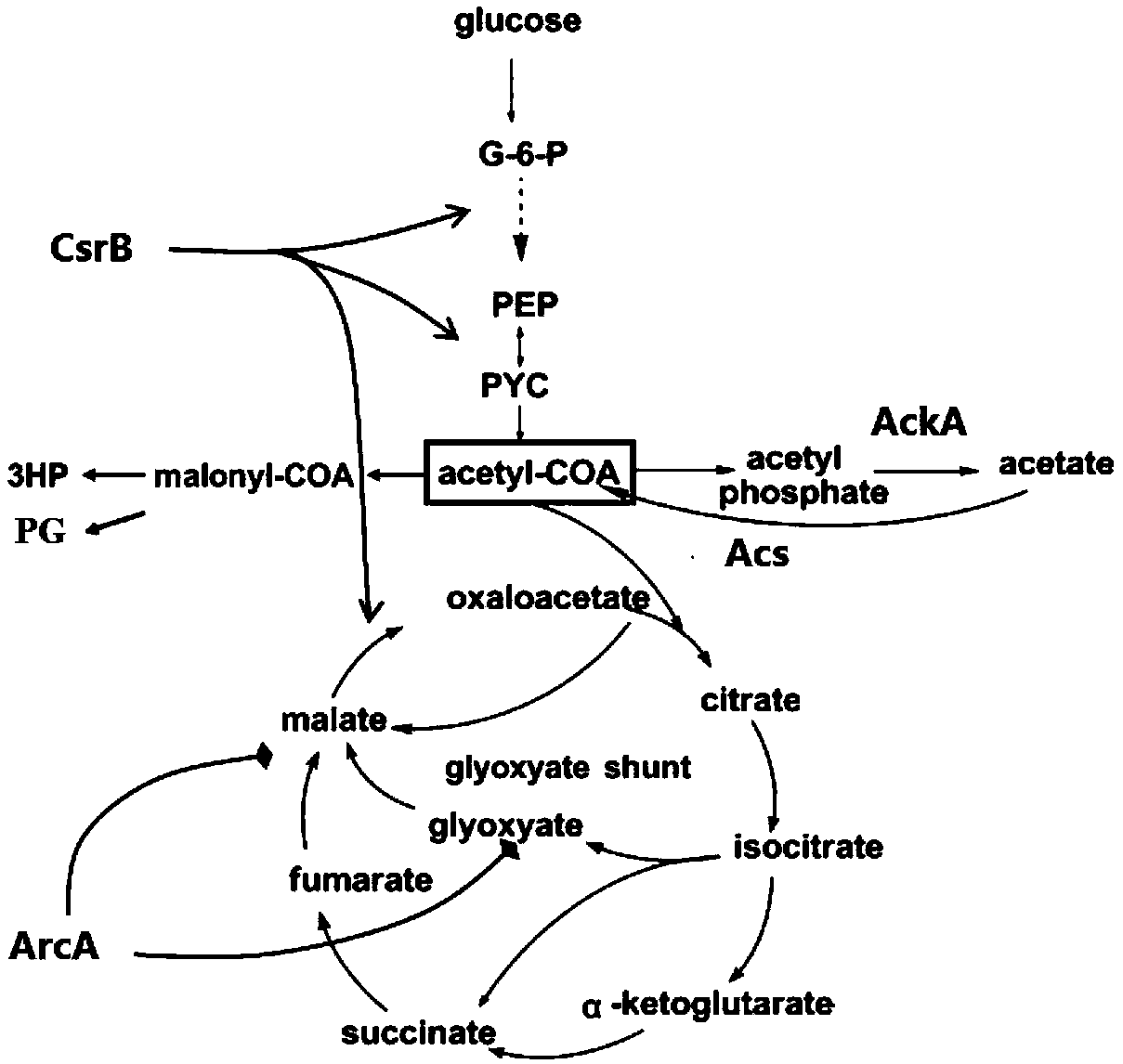

[0097] Example 2 Biosynthesis of Acetyl-CoA Derivatives

[0098] This embodiment lists the synthesis experiments of two important acetyl-CoA derivatives, phloroglucinol (PG) and 3-hydroxypropionic acid (3HP), to illustrate the general application of the chassis cells of the present invention in the biosynthesis of acetyl-CoA derivatives. sex.

[0099] 1. Detection of PG biosynthesis

[0100] 1. Construction of PG synthetic strains

[0101] Prepare the wild-type control strain E.coliBL21(DE3) and the acetyl-CoA derivative product general-purpose chassis cells (E.coli BL21(DE3)△arcA△ackAT7-csrB) constructed in Example 1 according to the operation steps of the TAKARA Competent Preparation Kit T7-acs), the recombinant plasmids pET-phlD-mar and pA-accADBC of the acetyl-CoA derivative product PG synthesis pathway (the construction method of the plasmid refers to Cao Y, et al.Improved phloroglucinol production by metabolically engineered Escherichia coli.Appl Microb Biotechnol 201...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com