Preparation method of capacitor

A technology of capacitors and electrolytes, which is applied in the fields of hybrid capacitor electrodes, electrolytic processes, electrolytic components, etc., can solve problems such as waste and achieve the effect of improving pseudocapacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

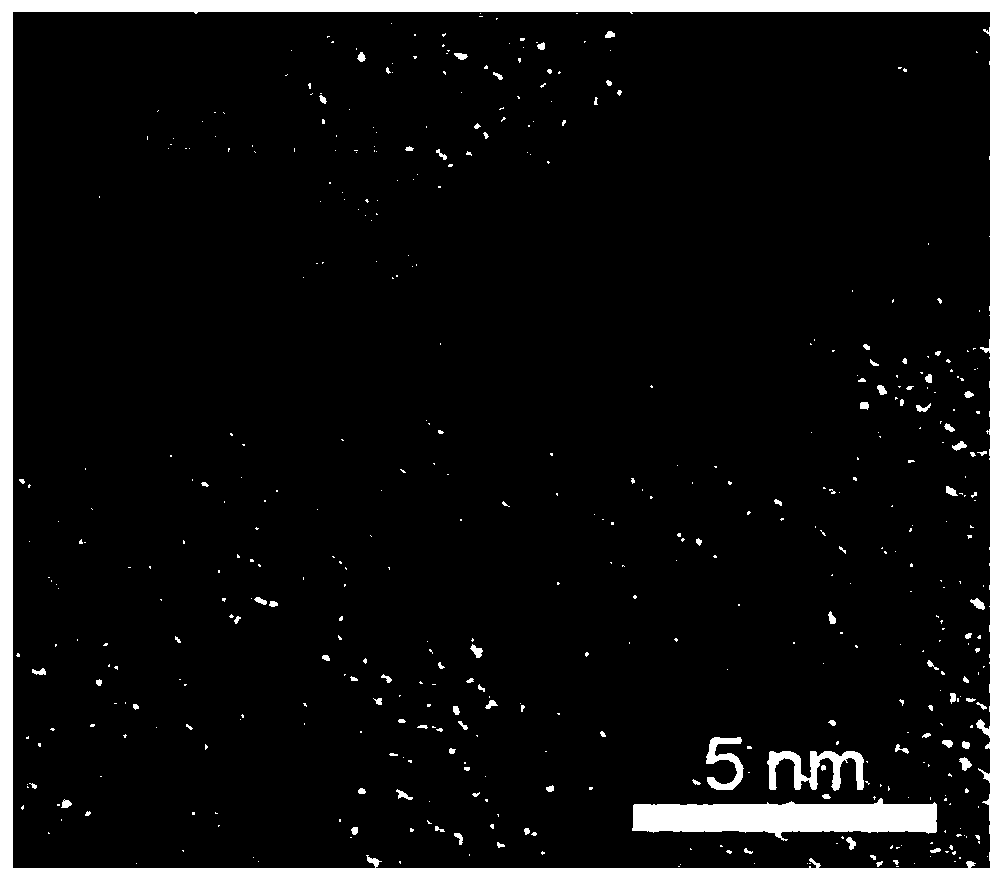

[0024] The polyimide film heat-treated at 1300°C was selected as the positive electrode material, immersed in 0.2mol / L ammonia water electrolyte, and electrolyzed at a voltage of 30V for 2 hours to obtain graphene carbon dots dispersed in the electrolyte.

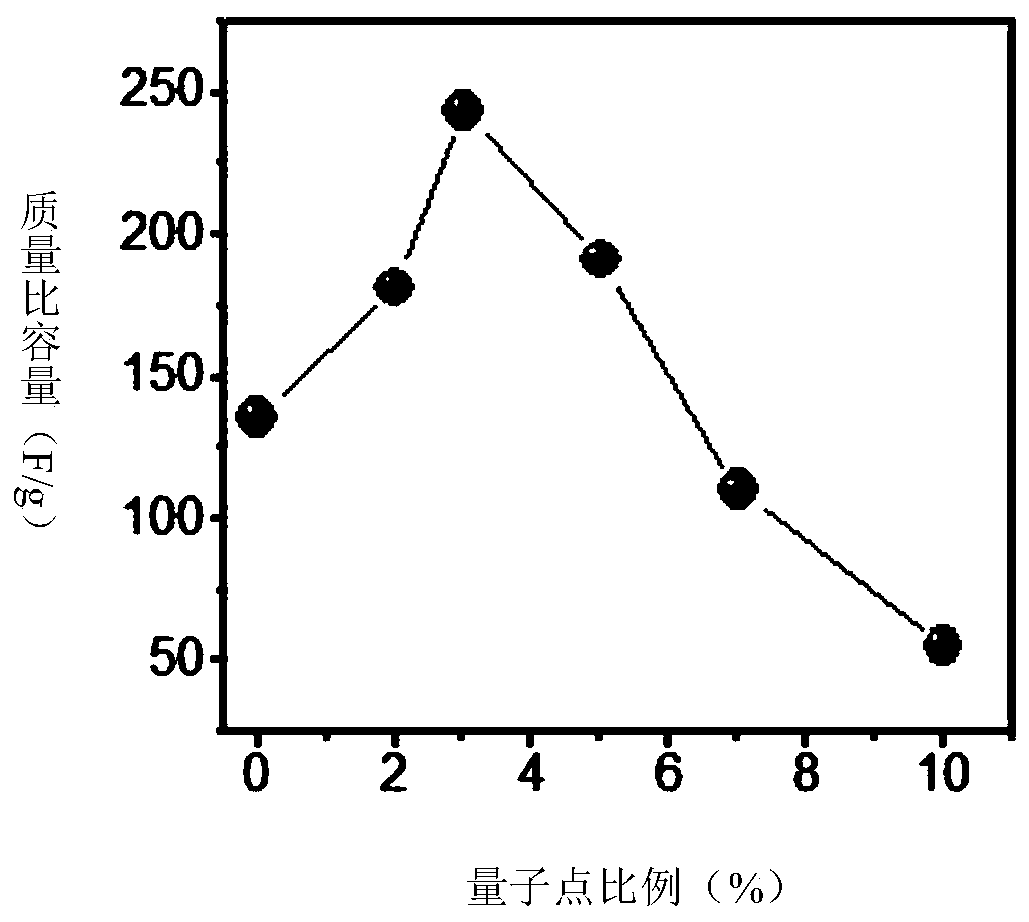

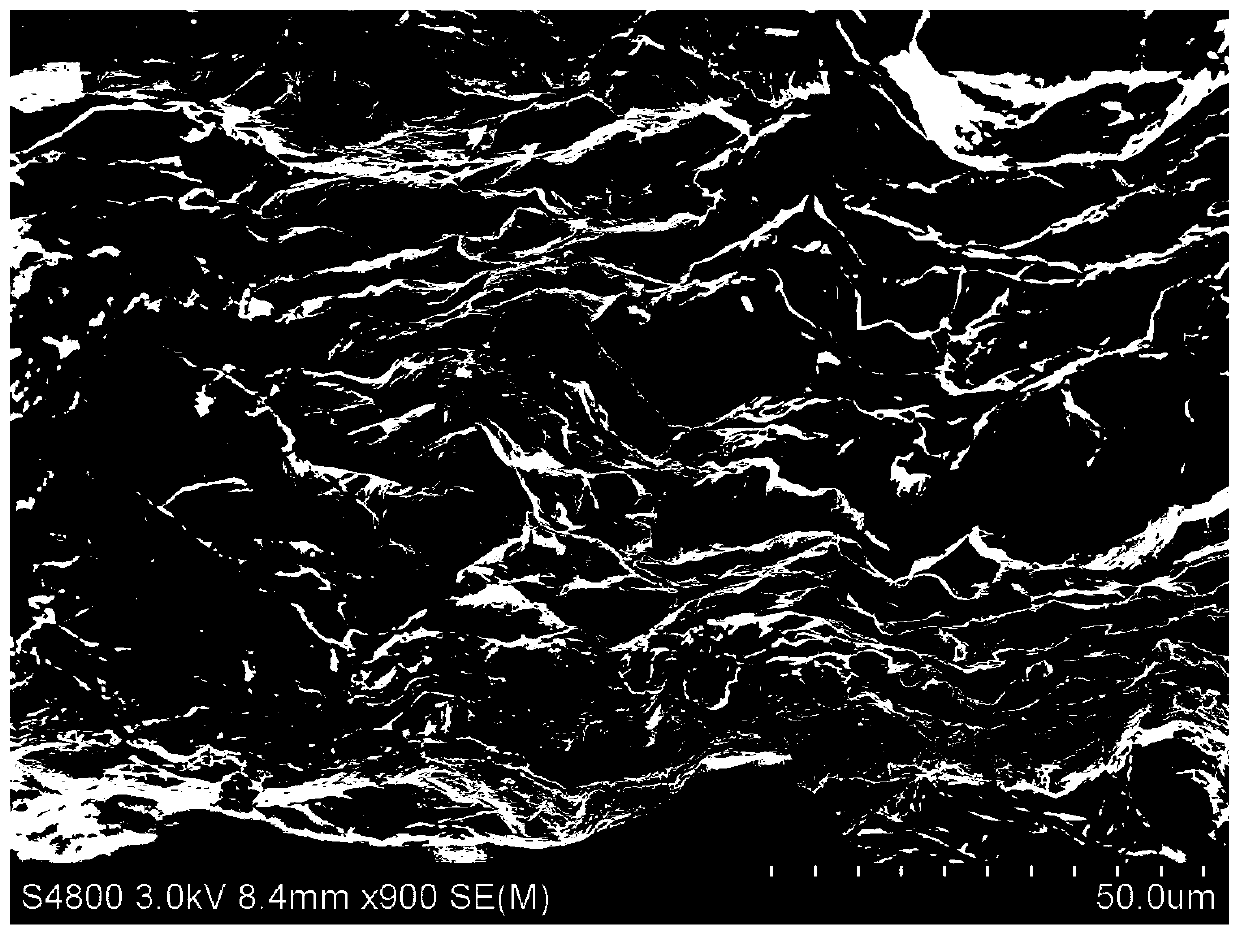

[0025] The graphene carbon dots obtained by the above method were removed by heating and evaporating ammonia water to obtain a graphene carbon dot dispersion liquid with a nitrogen content of 5%. Mix the graphene carbon dots with the graphene solution, the content of the graphene carbon dots is 1% of the total amount of the composite, freeze at -40°C, and then freeze-dry in a lyophilizer to obtain a 1mm thick air condensation glue. The airgel is placed in a reducing agent, which is a mixture of hydroiodic acid:ethanol:water with a volume ratio of 1:5:50. Then the reducing solution loaded with airgel was reduced in an oven at 90°C. The reduced airgel was washed repeatedly to remove the residue of hydroiodic acid, then soak...

Embodiment 2

[0028] Choose carbonized polyimide film at 1300°C as the positive electrode material, immerse in 0.2mol / L ammonia water electrolyte, and conduct electrolysis at a voltage of 30V for 2 hours;

[0029] Through the above steps, the graphene carbon dots dispersed in the electrolytic solution are obtained, the ammonia water is removed by heating and evaporating, and the graphene carbon dot dispersion liquid with a nitrogen content of 5% is obtained. Mix the graphene carbon dots with the graphene solution, the ratio of the graphene carbon dots is 3% of the composite, freeze at -40°C, and then freeze-dry in a lyophilizer to obtain an airgel with a thickness of 1 mm. The airgel is placed in a reducing agent, the reducing agent is a mixture of hydroiodic acid:ethanol:water, and the volume ratio of the three is 1:5:50. Then the reducing solution loaded with airgel was reduced in an oven at 90°C. The reduced airgel was washed repeatedly to remove the residue of hydroiodic acid, then soa...

Embodiment 3

[0031] Choose carbonized polyimide film at 1300°C as the positive electrode material, immerse in 0.2mol / L ammonia water electrolyte, and conduct electrolysis at a voltage of 30V for 2 hours;

[0032] Through the above steps, the graphene carbon dots dispersed in the electrolytic solution are obtained, the ammonia water is removed by heating and evaporating, and the graphene carbon dot dispersion liquid with a nitrogen content of 5% is obtained. Mix the graphene carbon dots with the graphene solution, the proportion of the graphene carbon dots is 5% of the composite, freeze at -40°C, and then freeze-dry in a lyophilizer to obtain an airgel with a thickness of 1 mm. The airgel is placed in a reducing agent, the reducing agent is a mixture of hydroiodic acid:ethanol:water, and the volume ratio is 1:5:50. Then the reducing solution loaded with airgel was reduced in an oven at 90°C. The reduced airgel was washed repeatedly to remove the residue of hydroiodic acid, then soaked in 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com