Preparation method of honeycomb porous carbon material

A porous carbon material and honeycomb-shaped technology, which is applied in the field of preparation of honeycomb porous carbon materials, can solve problems such as high production energy consumption, large environmental pollution, and complex waste water and waste gas treatment, and achieve simple operation, reduced process flow, and good application foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In one of the embodiments of the preparation method of a honeycomb porous carbon material of the present invention, measure 100 mL of lard, heat it to 120 ° C, put 5 g of glutinous rice in the oil solution, and heat the oil For dry frying, transfer the above-mentioned glutinous rice with increased volume after frying to a high-temperature tube furnace, under Ar atmosphere, at 5 ℃∙min -1 The heating rate was increased to 750 °C, and the temperature was kept constant for 60 min. After cooling, it was washed with distilled water to remove impurities, and centrifugally dried to obtain a honeycomb porous carbon material.

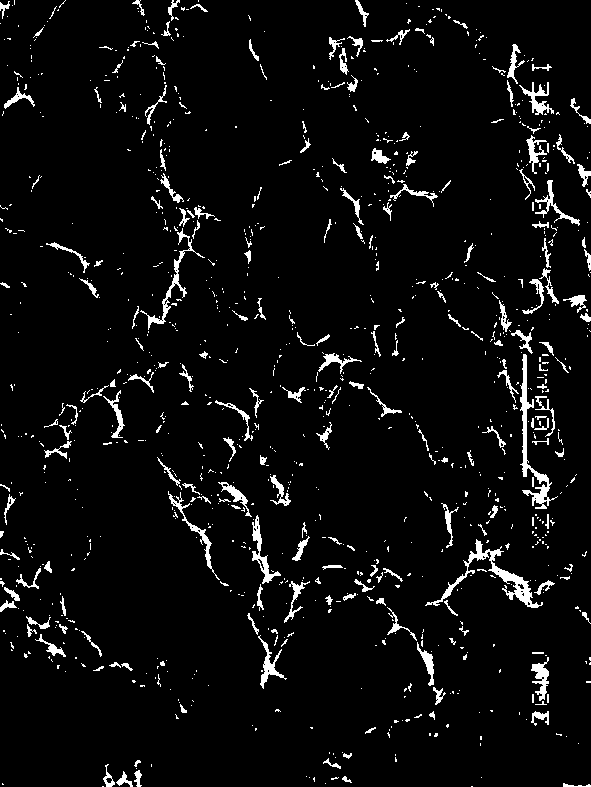

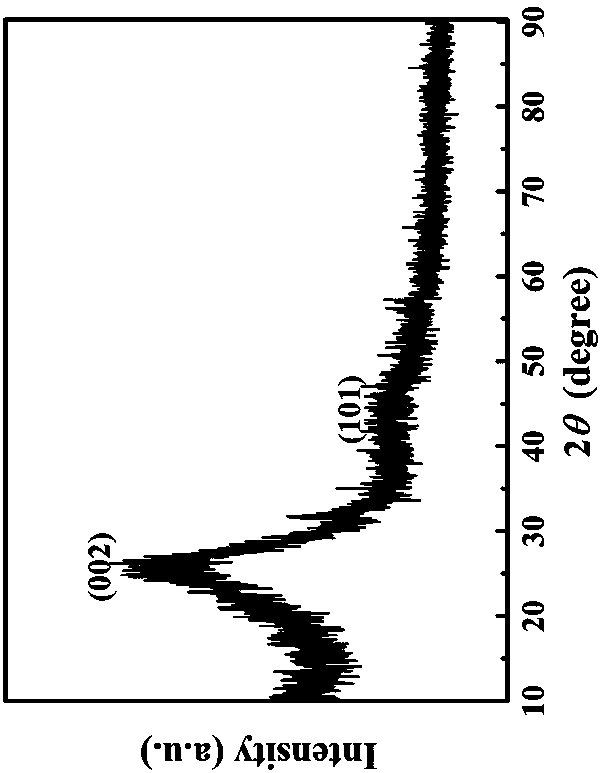

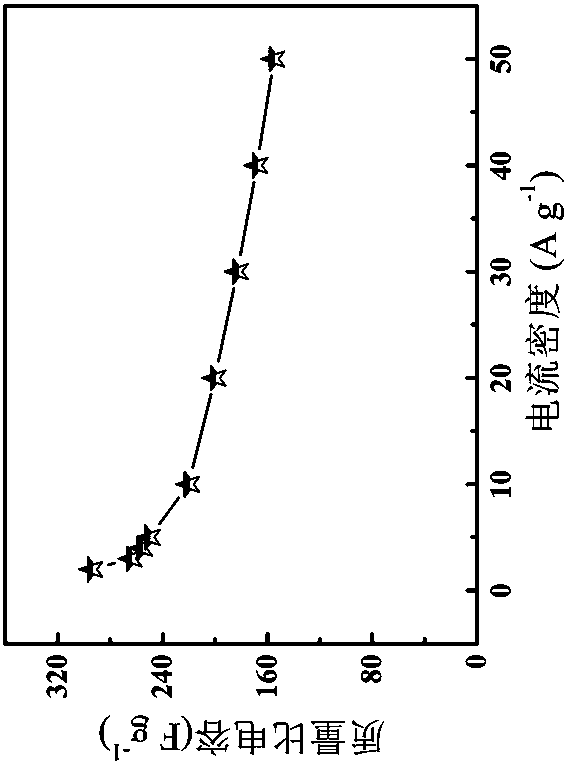

[0035] The physical and chemical properties of the prepared porous carbon materials were characterized by scanning electron microscopy and X-ray diffraction. The results are as follows: figure 1 with figure 2 As shown, the supercapacitor performance test was carried out on the prepared porous carbon material, and the results were as follows image 3 sho...

Embodiment 2

[0037] In one of the embodiments of the preparation method of a honeycomb porous carbon material of the present invention, measure 100 mL of peanut oil, heat it to 150 ° C, put 10 g of rice in the oil solution, and dry it in hot oil Fried, the above-mentioned fried rice with increased volume was transferred to a high-temperature tube furnace, under Ar atmosphere, at 10 ℃∙min -1 The heating rate was increased to 800 °C, and the temperature was kept constant for 90 minutes. After cooling, it was washed with distilled water to remove impurities, and centrifugally dried to obtain a honeycomb porous carbon material.

Embodiment 3

[0039] In one of the embodiments of the preparation method of a honeycomb porous carbon material of the present invention, measure 100 mL of soybean oil, heat it to 180 ° C, put 15 g of shrimp chips in the oil solution, and heat the oil For dry frying, transfer the above-mentioned glutinous rice with increased volume after frying to a high-temperature tube furnace, and heat it at 15 ℃∙min -1 The heating rate was increased to 850 °C, and the temperature was kept constant for 120 min. After cooling, it was washed with distilled water to remove impurities, and centrifugally dried to obtain a honeycomb porous carbon material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com