Multifunctional partitioning denitrification integrated method and multifunctional partitioning denitrification integrated device

A denitrification and multi-functional technology, applied in chemical instruments and methods, anaerobic digestion treatment, special compound water treatment, etc., can solve the problems of large floor area, high operating cost, and many equipment, and achieve small floor space , improve efficiency, save floor area and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

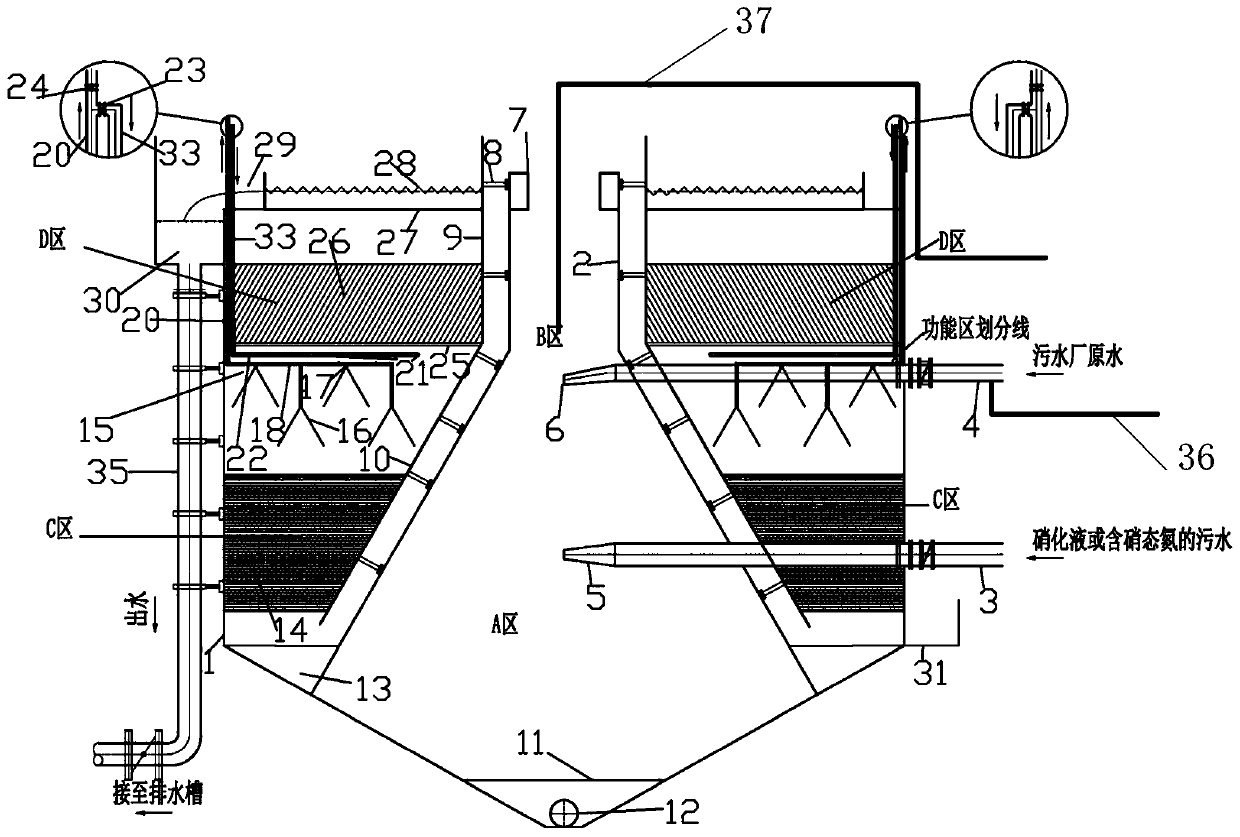

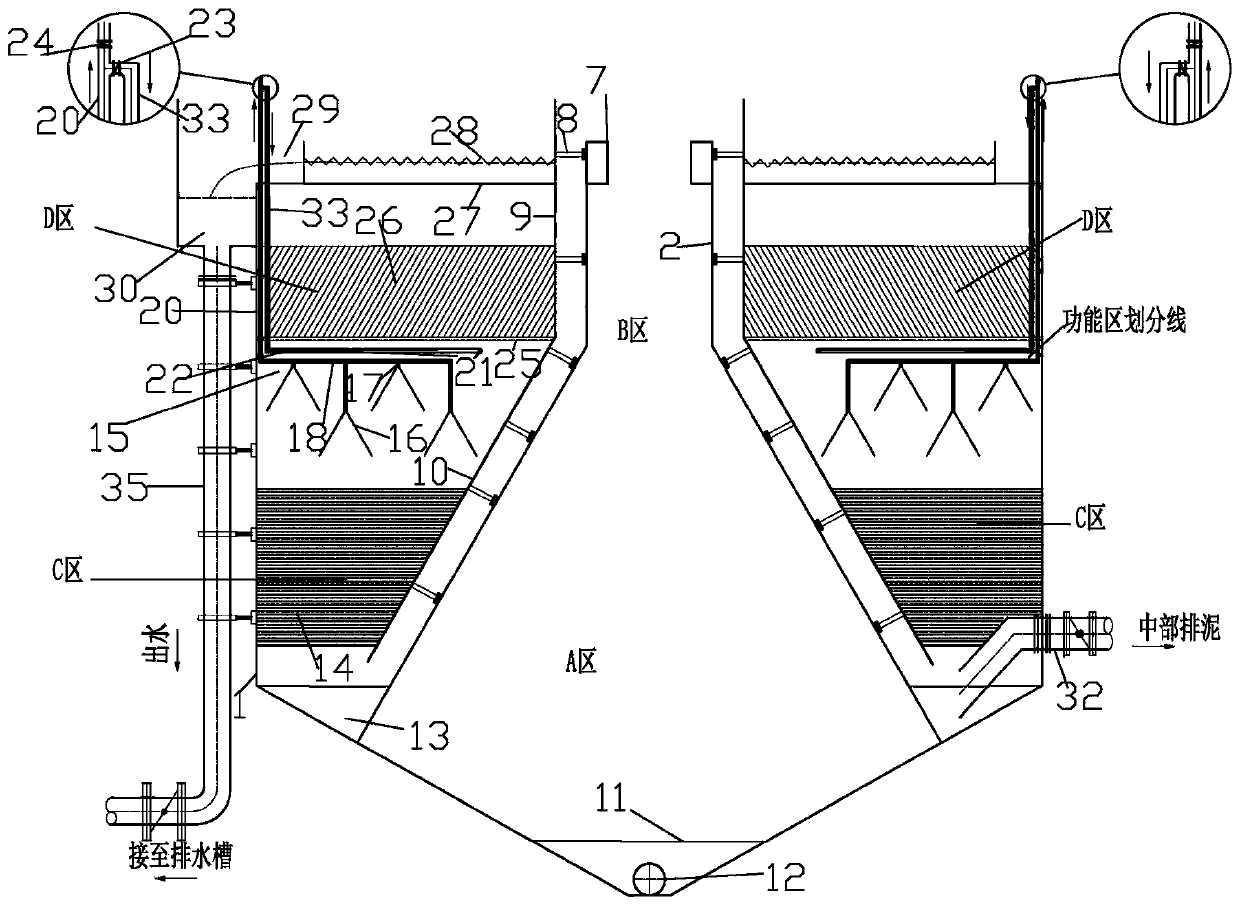

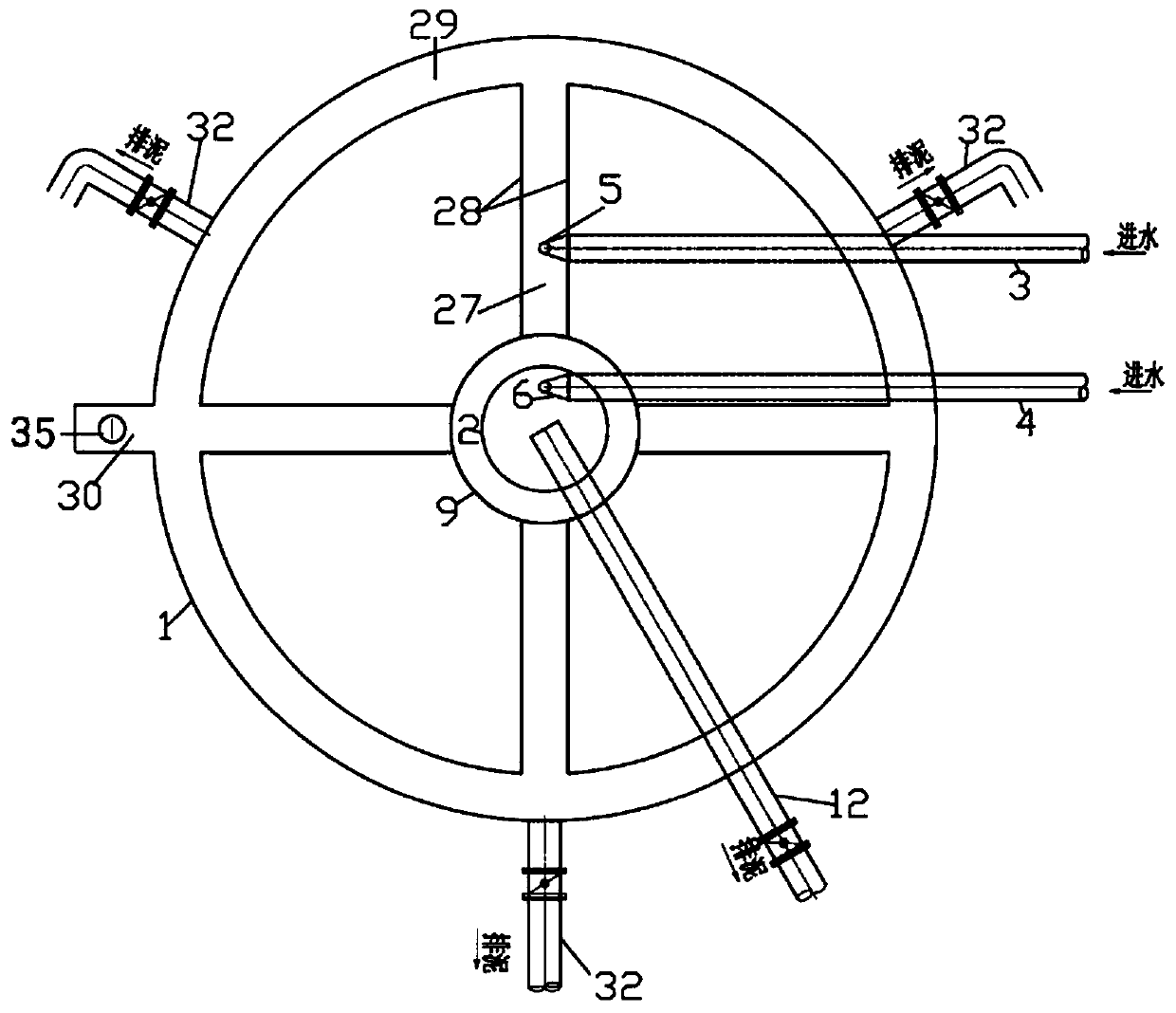

[0046] Such as figure 1 , figure 2 As shown, the denitrification integrated equipment with multifunctional partitions of the present invention is divided into an inner tank 2 and an outer tank 1 according to the structure, the outer tank 1 is a cylindrical structure, the bottom of the tank body is conical, and the upper part of the inner tank 2 is a hollow cylinder , the lower part is trumpet-shaped, and there are annular sump 29, straight sump 27, inclined plate 26, denitrification packing layer 14 and central mud collection area 13 distributed from top to bottom between the inner tank and the outer tank; Vertical guide tube 9 and oblique guide tube 10 are distributed on the outer wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com