Treatment system for organic sewage in contaminated site remediation process

A technology of organic sewage and treatment system, applied in the field of contaminated site restoration, can solve the problems of reduced treatment efficiency, secondary pollution, narrow application range, etc., and achieve the effect of simple process flow, strong treatment capacity and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Some specific embodiments of the present invention will be described in detail below in an exemplary and non-limiting manner with reference to the accompanying drawings. The same reference numerals in the drawings designate the same or similar parts or parts. It should be understood by those skilled in the art that these drawings are not necessarily drawn to scale.

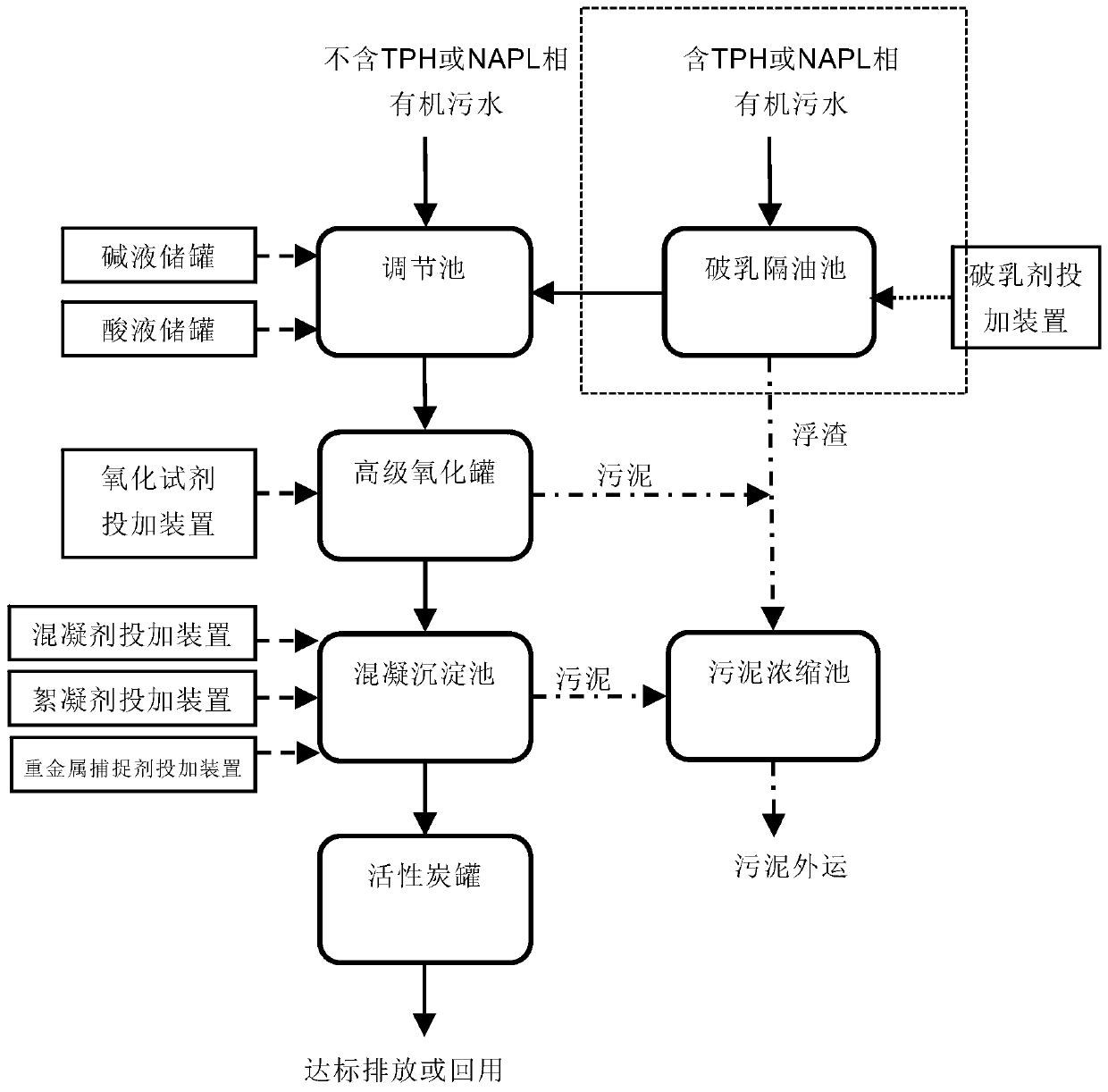

[0031] Such as figure 1 As shown, the present invention provides a treatment system for organic sewage in the process of remediation of contaminated sites, including: demulsification grease trap, regulating tank, advanced oxidation tank, coagulation sedimentation tank and activated carbon tank; its composition structure and work flow are as follows :

[0032] The demulsification grease trap is a pretreatment unit. If the organic sewage contains petroleum hydrocarbon (TPH) or non-aqueous fluid (NAPL phase) pollutants, the sewage enters the demulsification grease trap for pretreatment; for phases containing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com