Synthesis device and synthesis method of 1,3-butanediol

A synthesis device and technology for butanediol are applied in chemical instruments and methods, preparation of carbonyl compounds by condensation, preparation of hydroxyl compounds, etc., and can solve the problems of unsatisfactory yield and purity of 1,3-butanediol, pungent odor, Complex process and other problems, to achieve the effect of large implementation value, short process and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

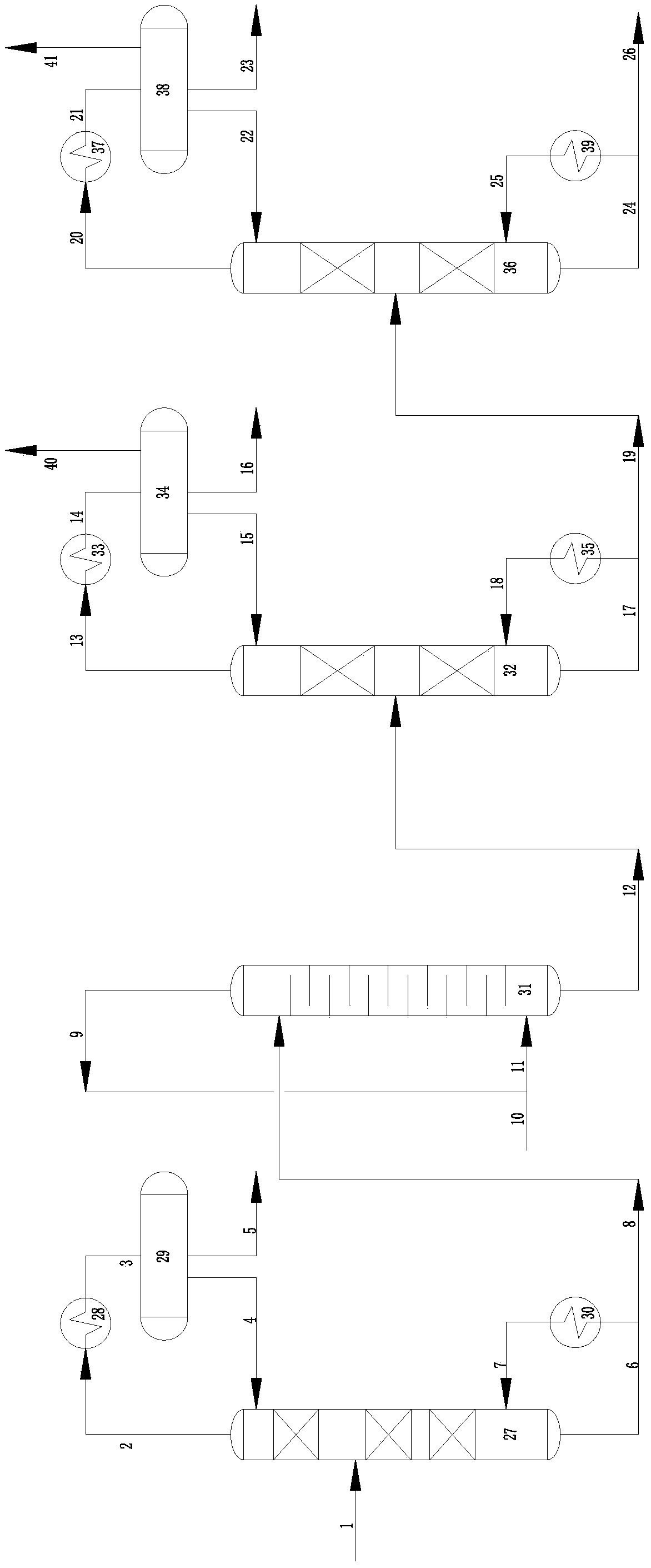

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0030] Such as figure 1 Shown, a kind of synthesis device of 1,3-butanediol comprises the condensation reaction system, hydrogenation reaction system and vacuum refining system connected successively by pipeline; The condensation reaction system adopts the reactive distillation of loaded basic anion resin Tower 27; the hydrogenation reaction system uses a tower type hydrogenation reactor 31; the vacuum refining system includes a light removal tower 32 and a weight removal tower 36.

[0031] The top of the reactive distillation tower 27 is connected to the overhead condenser 28 of the reactive distillation tower through a pipeline, and the bottom of the reactive distillation tower 27 is connected to the reactive distillation tower reboiler 30 and the tower hydrogenation reactor 31 through a pipeline The reactive distillation tower top condenser 28 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com