Refining method of thymol

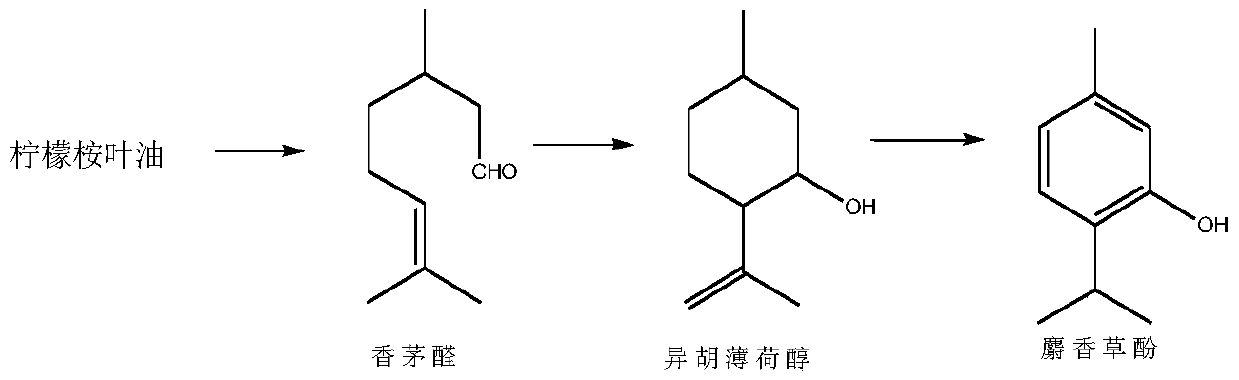

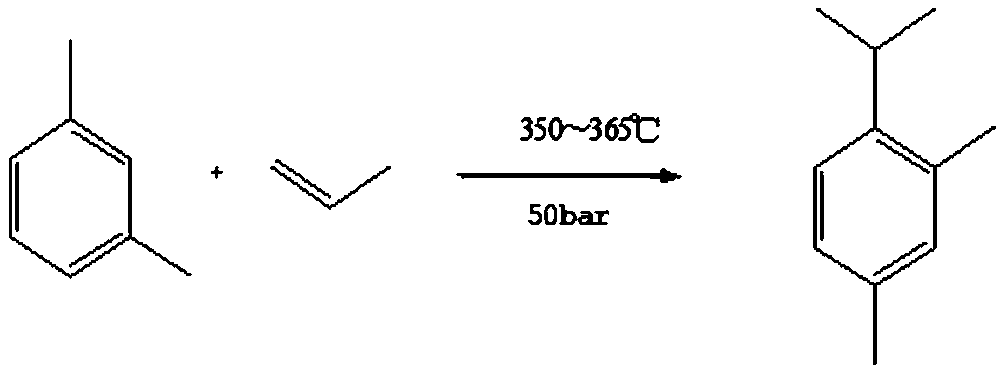

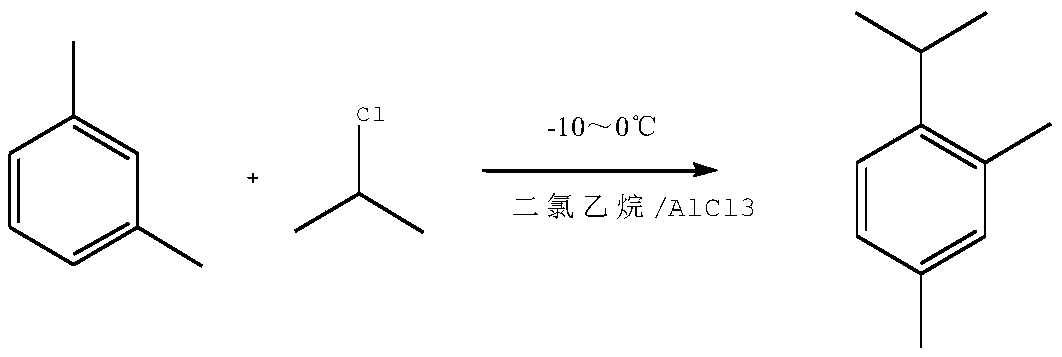

A technology of thymol and a refining method is applied in the field of medicine and chemical industry, and can solve the problems of impurities such as citronellal and isopulegol, and achieve the effects of improving product purity, simple refining method and reducing refining cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Add 250g of industrial grade thyme to a 1000ml three-necked flask, add 200ml of n-hexane solvent, pour in nitrogen to replace the air in the reaction flask, under the protection of nitrogen, turn on the stirring, heat up to 70±3℃, keep warm and stir for 0.5 hours to make the thyme brain Fully dissolve and clear; add 2.5g of activated carbon, heat preservation and decolorization for about 1h; filter, the filtrate naturally cools down, slowly stir until granular solids precipitate on the wall of the reaction vessel, adjust the stirring speed, heat preservation and stir quickly for about 1h, and a large amount of crystalline solids ( About 40°C), cool to 5°C, keep stirring and crystallize for 4 hours, filter to obtain 233 g of pure white product, and dry to obtain 214 g of white transparent crystalline powder solid.

Embodiment 2

[0039] Add 250g of industrial grade thyme to a 1000ml three-necked flask, add 250ml of n-heptane solvent, pour in nitrogen to replace the air in the reaction flask, under the protection of nitrogen, turn on stirring, heat up to 75±3℃, keep warm and stir for 0.5 hours to make thyme The brain is fully dissolved; add 5.0g of activated clay, decolorize for about 30min after heat preservation; filter, the filtrate cools naturally, slowly stir until granular solids precipitate on the wall of the reaction vessel, adjust the stirring speed, heat preservation and stir quickly for about 2h, and a large amount of crystals will be precipitated The solid (about 40°C), cooled to 3°C, kept stirring and crystallized for 2 hours, filtered to obtain 231 g of pure white product, and dried to obtain 206 g of white transparent crystalline powder solid.

Embodiment 3

[0041] Add 250g of industrial grade thyme brain to a 1000ml three-necked flask, add 250ml of n-octane solvent, and pass nitrogen to replace the air in the reaction flask. Under the protection of nitrogen, turn on the stirring, heat up to 65±3℃, keep warm and stir for 0.5 hours to make the thyme The brain is fully dissolved; add 2.0g of chromatographic silica gel powder, decolorize after heat preservation for about 1h; filter, the filtrate cools naturally, slowly stir until granular solids precipitate on the wall of the reaction vessel, adjust the stirring speed, heat preservation and stir quickly for about 2h, and a large amount of precipitation The crystalline solid (about 40°C) was cooled to 1°C, kept stirring and crystallized for 6 hours, filtered to obtain 248 g of pure white product, and dried to obtain 186 g of white transparent crystalline powder solid.

[0042] The white transparent crystalline powder solid obtained in Examples 1-3 of the present invention was subjected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com