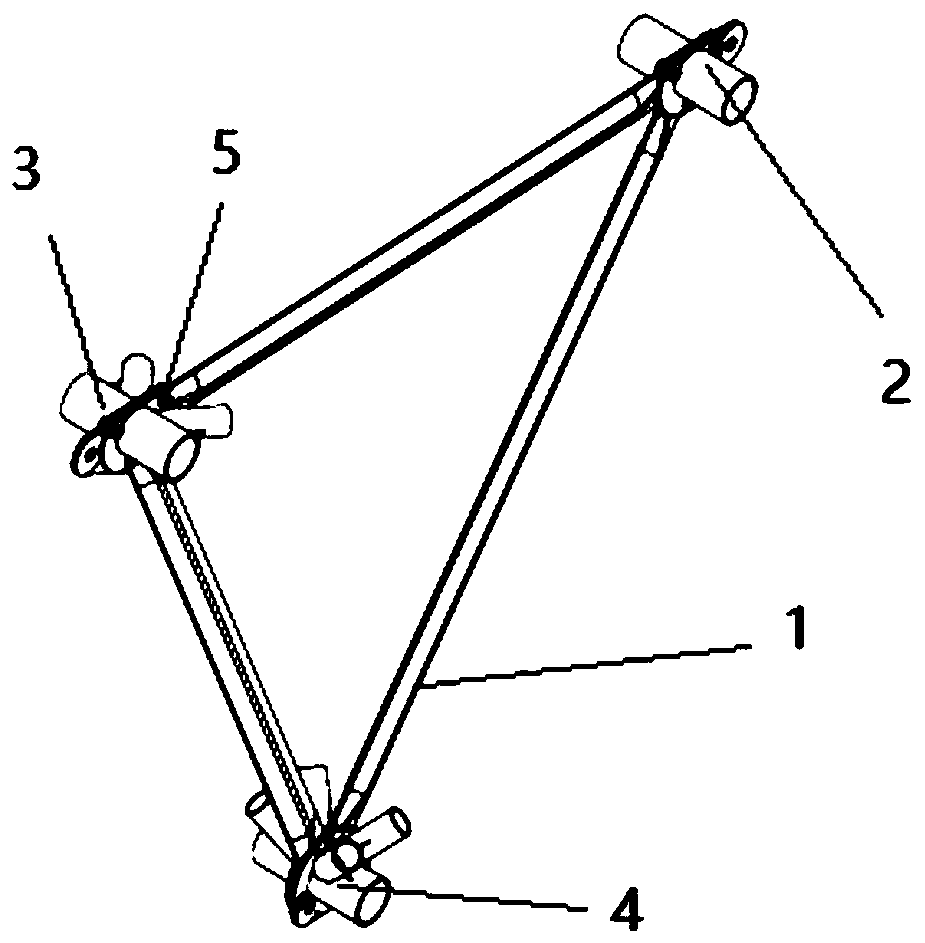

Large triangular composite material pipe truss modular connecting joint

A technology for composite material tubes and connecting nodes, which is applied to the connection of rods, connecting components, fuselage frames, etc., can solve the problems of complex configuration, difficult manufacture, and small force, and achieve reasonable structural force and force transmission. Easy installation and integration, large bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

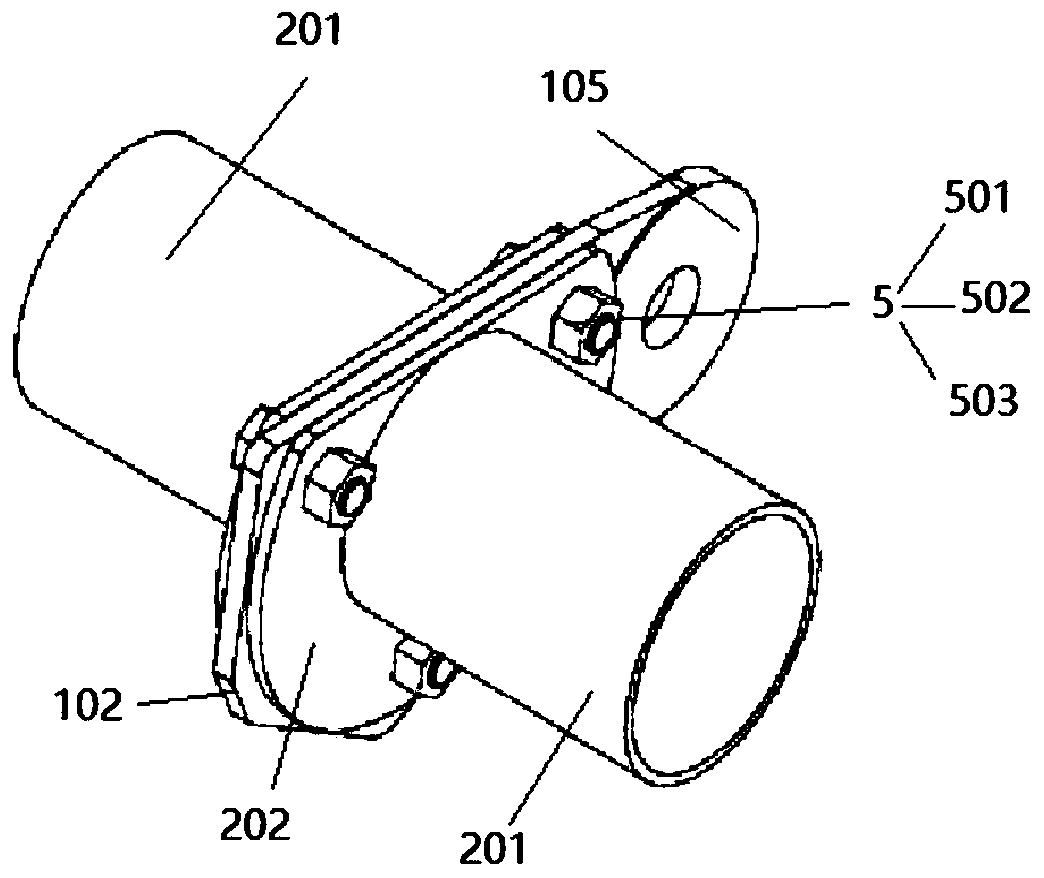

[0041] Pipe end node A2: the connecting sleeve 201 of the chord pipe is T700S, layup [±45° / 0° / 0° / 0°]3, connection flange G202, connection flange H 302 and connection flange J402 are all 2.0 thick, connection bolt pair 5 is M5, corner joints Plate D102, corner gusset E103 and corner gusset F104 are all 3.0 thick, T700S, layup [±45° / 0° / 0° / 0°]6.0.5 thickness (T700S, layup [±45° / 0° / 0° / 0°]) The connecting flange and the connecting sleeve of the chord tube are solidified once and formed, and the connecting flange with a thickness of 1.5 (15 layers of twill) is formed by secondary bonding.

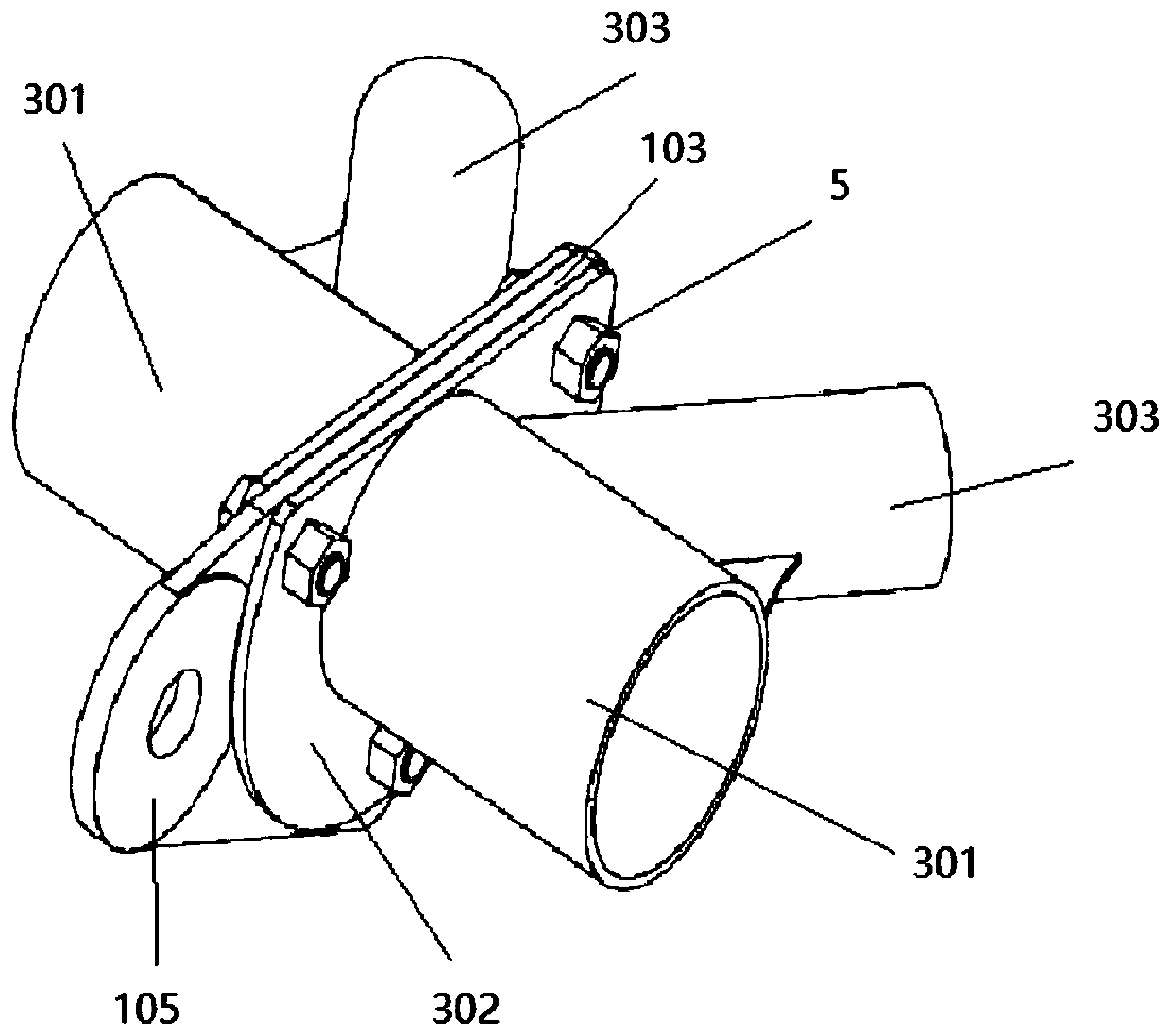

[0042] Pipe end node B3 and pipe end node C4:

[0043] The chord tube connection sleeve 301 and the chord tube connection sleeve 401 are T700S, layer [±45° / 0° / 0° / 0°] 3, web pipe connection sleeve 303, web pipe connection sleeve 403 and web pipe connection sleeve 404 are all T700S, ply[±45° / 0° / 0° / 0° / 0°]2, connecting flange 20102 is 2.0, connecting bolt pair 3 is M5, corner gusset plate 1020...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com