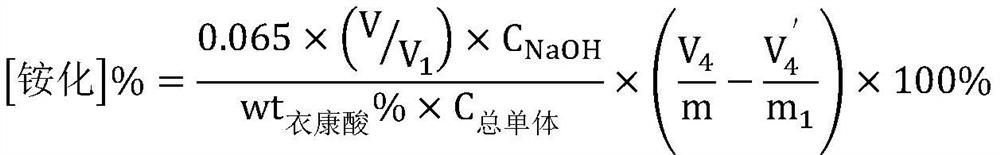

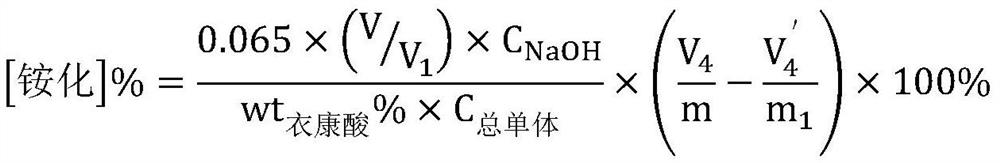

A detection method for ammonia ion replacement rate of polyacrylonitrile spinning solution

A technology of polyacrylonitrile spinning and ion replacement, which is applied in the direction of chemical analysis by titration method, can solve problems such as difficulty in controlling the degree of ammoniation, and achieve the effect of accurate control of dosage and residence time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Step 1. Take the spinning solution to be tested in a weighing bottle, weigh 1-2g of the spinning solution on a multi-position balance by the subtraction method, and put it on one end of the glass rod, accurate to 0.0001g, and record it as m=1.1258g.

[0043] Step 2. The end of the glass rod stained with the sample takes the center of the glass plate as the center, and rotates slowly against the glass plate to evenly spread it into a thin layer;

[0044] Step 3. Measure the hydrochloric acid standard solution of quantitative V = 25ml to rinse the samples on the glass plate and glass rod, completely collect the rinse water in the iodine bottle, and be careful not to leak out. The sample contacts the rinse water to solidify into a film, and use tweezers Gently remove the film into the iodine bottle, wash the surface of the glass plate with the remaining hydrochloric acid solution, and completely collect the cleaning water into the iodine bottle of rinsing water. Cover the ...

Embodiment 2

[0053] Step 1. Take the spinning solution to be tested in a weighing bottle, weigh 1-2 g of the spinning solution on a multi-position balance by the subtraction method, and put it on one end of the glass rod, accurate to 0.0001 g, and record it as m=1.5116 g.

[0054] Step 2. The end of the glass rod stained with the sample takes the center of the glass plate as the center, and rotates slowly against the glass plate to evenly spread it into a thin layer;

[0055] Step 3. Measure the hydrochloric acid standard solution of quantitative V = 25ml to rinse the samples on the glass plate and glass rod, completely collect the rinse water in the iodine bottle, and be careful not to leak out. The sample contacts the rinse water to solidify into a film, and use tweezers Gently remove the film into the iodine bottle, wash the surface of the glass plate with the remaining hydrochloric acid solution, and completely collect the cleaning water into the iodine bottle of rinsing water. Cover t...

Embodiment 3

[0064] Step 1. Take the spinning solution to be tested in a weighing bottle, weigh 1-2 g of the spinning solution on a multi-position balance by the subtraction method, and place it on one end of the glass rod, accurate to 0.0001 g, and record it as m=1.8718 g.

[0065] Step 2. The end of the glass rod stained with the sample takes the center of the glass plate as the center, and rotates slowly against the glass plate to evenly spread it into a thin layer;

[0066] Step 3. Measure the hydrochloric acid standard solution of quantitative V = 25ml to rinse the samples on the glass plate and glass rod, completely collect the rinse water in the iodine bottle, and be careful not to leak out. The sample contacts the rinse water to solidify into a film, and use tweezers Gently remove the film into the iodine bottle, wash the surface of the glass plate with the remaining hydrochloric acid solution, and completely collect the cleaning water into the iodine bottle of rinsing water. Cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com