Method for preparing two-dimensional transition metal sulfide through directional transfer CVD method

A transition metal, transfer method technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc., can solve the problem of difficult transfer evaporation of sapphire, damage to the material surface, introduction of impurities, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

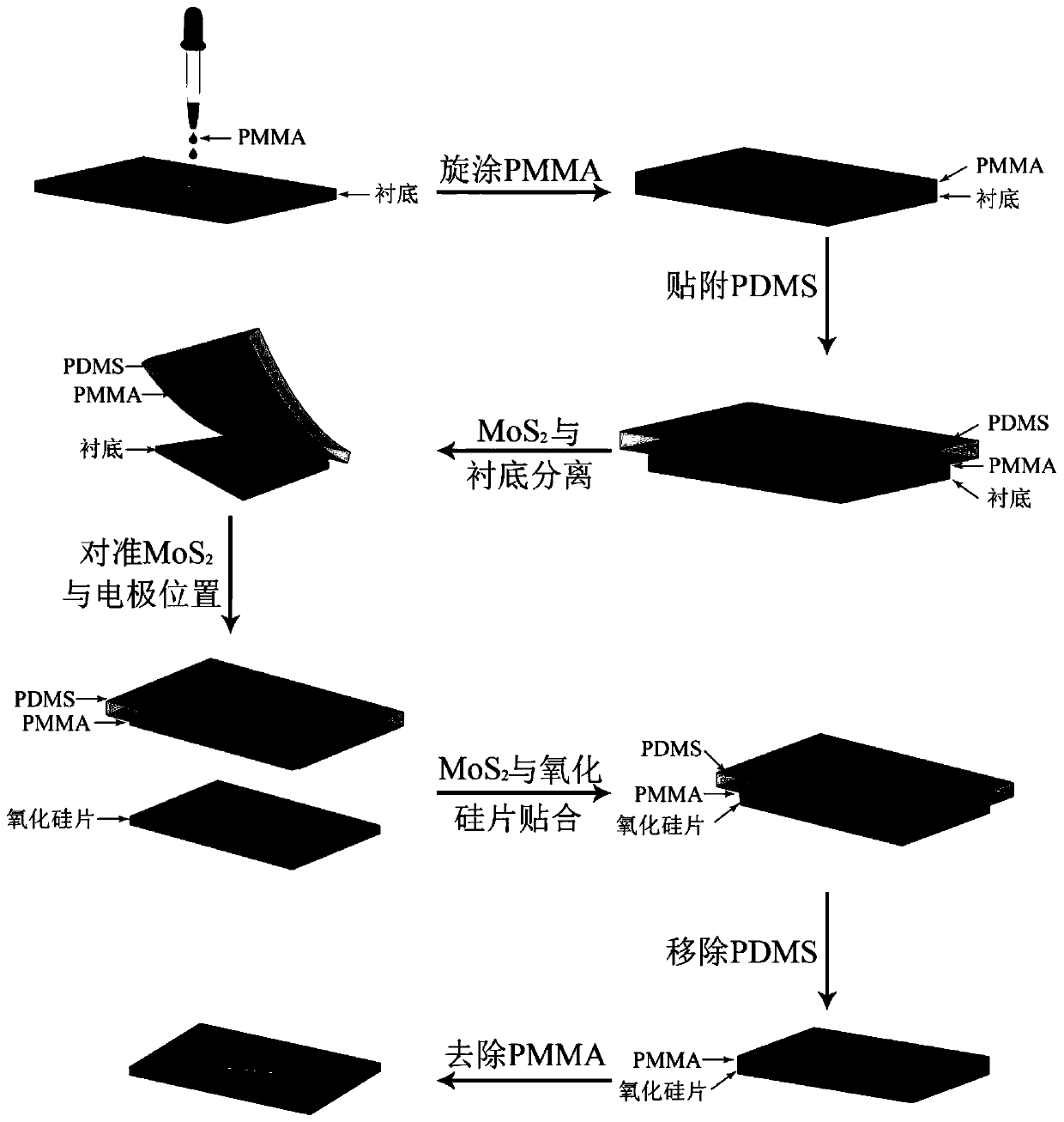

[0030] see figure 1 , a method for preparing two-dimensional transition metal sulfides by directional transfer CVD, specifically comprising the steps of:

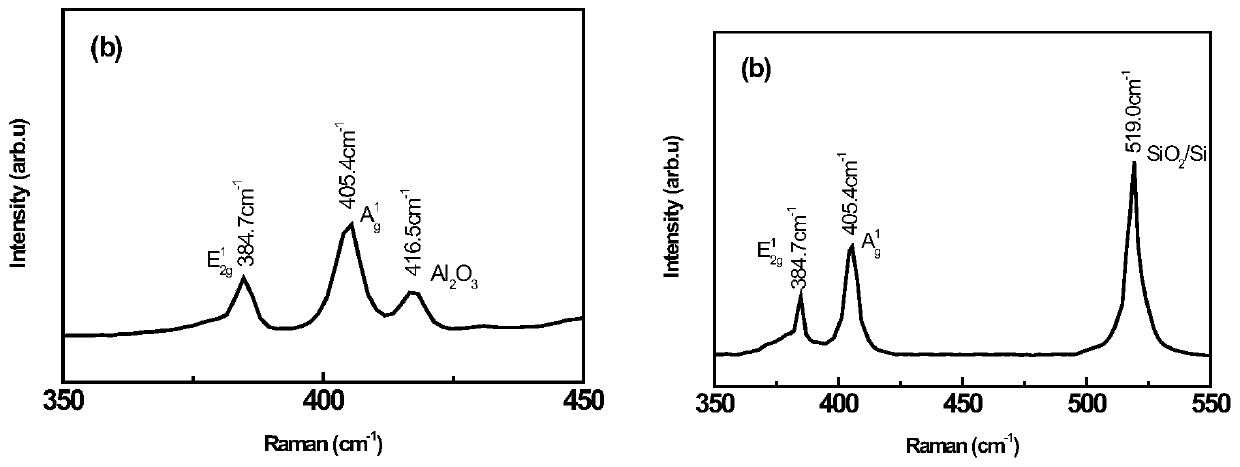

[0031] Step 1: Provide MoS grown on one side 2 Growth substrate for thin films, here MoS prepared by CVD 2 Thin-film sapphire substrate, see 2(a). MoS 2 The side length of the film is about 60 μm; when MoS 2 When the number of layers decreases, the van der Waals force gradually increases, and the corresponding peak of sulfur atoms vibrating in the horizontal plane There is less blue shift, and the sulfur atoms vibrate in a corresponding peak perpendicular to the horizontal plane A redshift occurs, resulting in a wavenumber reduced, monolayer MoS 2 thin film and The wave number difference is about 21cm -1 . on the sapphire substrate The peak is 384.7 cm -1 , The peak is 405.4cm -1 , the wave number difference between the two peaks △=20.7cm -1 , the MoS 2 The number of film layers is single layer, see ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com