Thermoplastic resin composition

一种热塑性树脂、组合物的技术,应用在热塑性树脂组合物领域,能够解决减少的白化机械特性、着色性能和表面光泽度热塑性树脂组合物等问题,达到优异着色性能、减少白化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] Hereinafter, each step of the preparation method of the first graft copolymer is described in detail.

[0041] 1) Preparation of alkyl (meth)acrylate polymers

[0042] First, an alkyl (meth)acrylate polymer can be produced by emulsion-polymerizing an alkyl (meth)acrylate monomer.

[0043] The alkyl (meth)acrylate monomer may be one or more selected from methyl acrylate, ethyl acrylate, butyl acrylate and ethylhexyl acrylate. Among them, butyl acrylate is preferable.

[0044] Emulsion polymerization may be performed in the presence of one or more selected from emulsifiers, initiators, crosslinking agents, grafting agents, electrolytes and water.

[0045] The emulsifier can be selected from C 12 to C 18 Metal salt derivatives of alkylsulfosuccinic acids and C 12 to C 20 One or more of metal salt derivatives of alkyl sulfate esters.

[0046] The C 12 to C 18 The metal salt derivative of alkyl sulfosuccinic acid can be selected from dicyclohexyl sodium sulfosuccina...

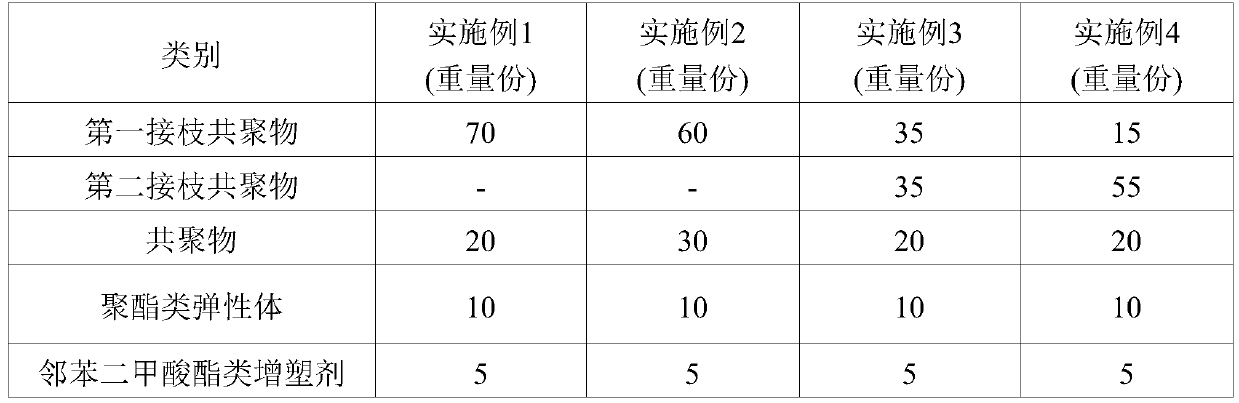

Embodiment 1

[0164] Add 70 parts by weight of the first graft copolymer (average particle size: 130 nm, core: 50% by weight of units derived from butyl acrylate polymer, shell: 30% by weight of units derived from styrene and 20% by weight of unit derived from acrylonitrile), 20 parts by weight of SAN copolymer (manufacturer: LG Chemical, product name: 90HR, weight average molecular weight: 150,000 g / mol) as a copolymer, 10 parts by weight of polyester-based elastomer ( Manufacturer: LG Chemical, product name: KEYFLEXBT2140D resin, Shore D hardness: 43), 5 parts by weight of diisopropyl phthalate as a phthalate plasticizer, 3 parts by weight of The EBS resin (manufacturer: SUNKOO) of agent, the Irgranox 1076 (product name, manufacturer: BASF) of 0.4 weight part as antioxidant, the Irgrafos 168 (product name, manufacturer: BASF) of 0.4 weight part, 0.6 weight part Tinuvin 770 (product name, manufacturer: BASF) as an ultraviolet stabilizer and 0.6 parts by weight of Sunsorb 329 (product name,...

Embodiment 2

[0167] A sample was produced in the same manner as in Example 1 except that 60 parts by weight of the first graft copolymer and 30 parts by weight of the SAN copolymer were added.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com