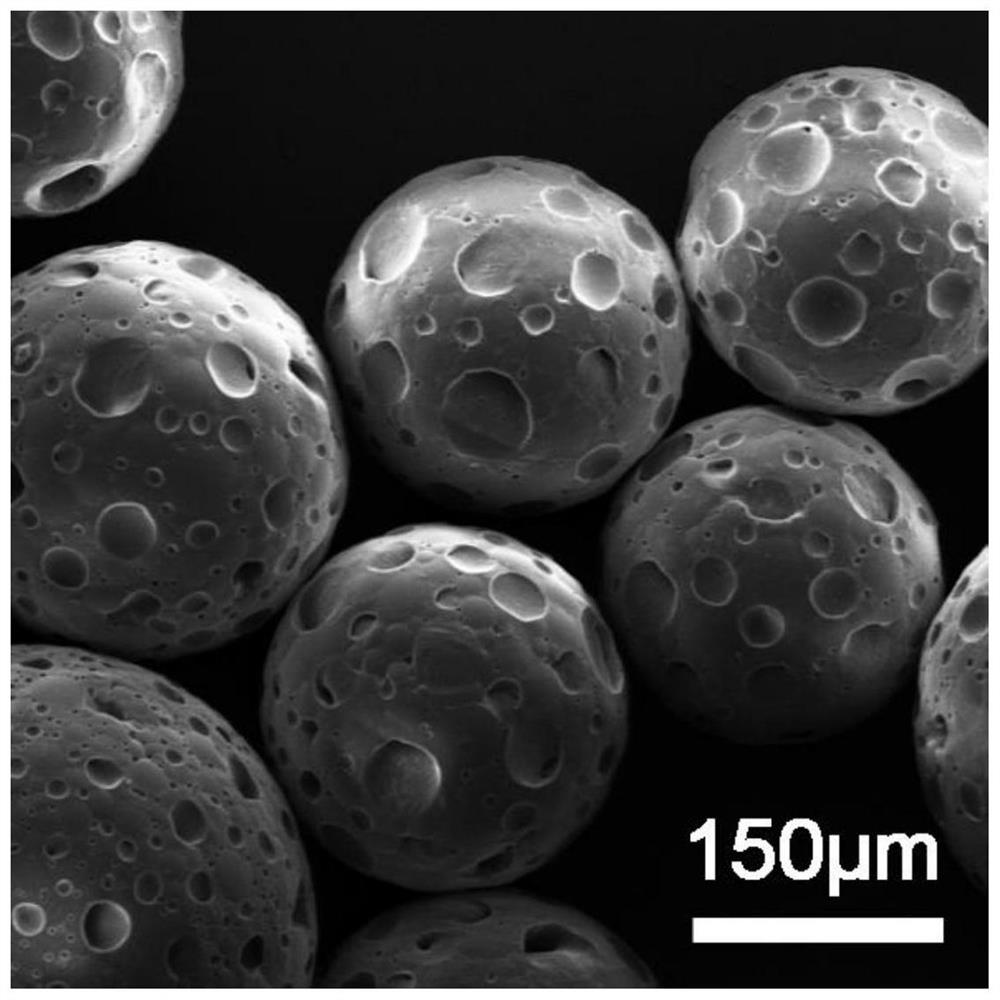

Golf ball-shaped degradable microspheres with microtopological structure and preparation method thereof

A topology and golf ball technology, applied in the field of golf ball degradable microspheres and its preparation, can solve the problems of catalysts and toxic chemical residues, promote cell adhesion and growth, stimulate the expression and preparation of metabolites The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

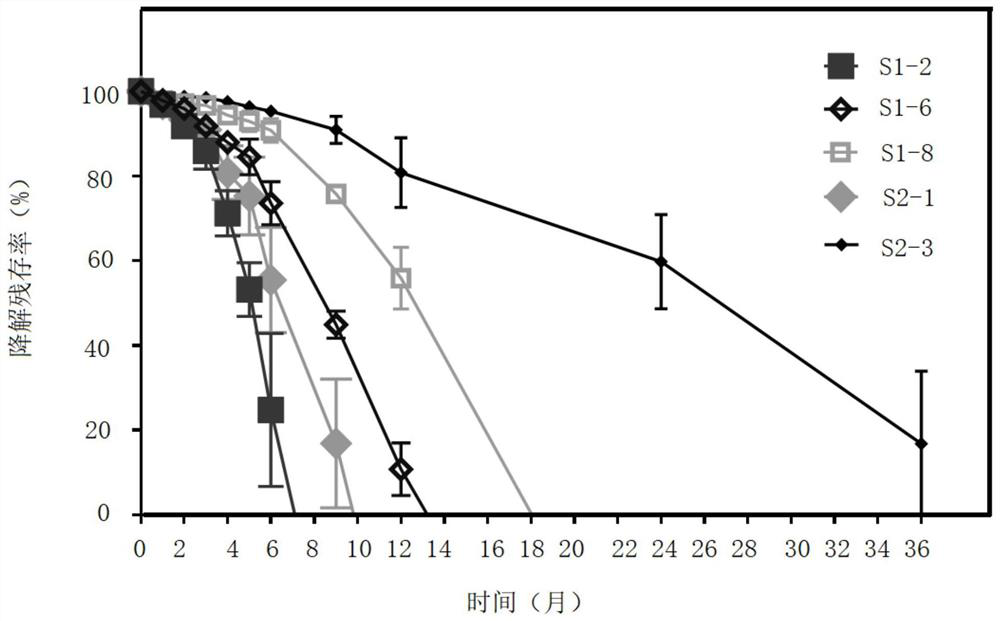

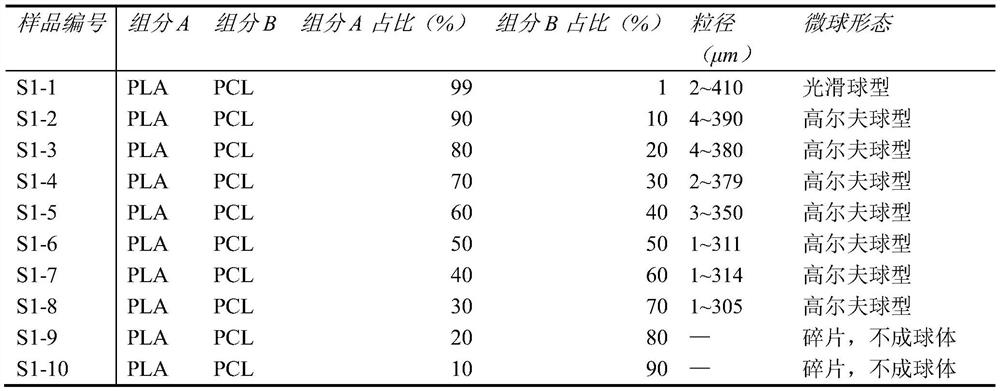

[0028] Example 1. To investigate the influence of the proportion of PCL in component B on the preparation of golf microspheres.

[0029] Step 1: Add a total of 1 g of component A polylactic acid (molecular weight: 100KD) and component B polycaprolactone (molecular weight: 40KD) according to 99:1, 90:10, 80:20, 70:30, 60:40, The mass ratio of 50:50 is dissolved in 20ml of dichloromethane component C together to form the material concentration of 5% biological mixture solution component D;

[0030] Step 2: Add component D to 200ml of 0.1% PVA stabilizer solution component E, and form emulsion component F by stirring and mixing;

[0031] Step 3: Continue stirring and mixing until the organic solution in component F is completely volatilized to form component G.

[0032] Step 4: Wash component G with water or buffer solution as required, remove residual stabilizer solution component E, and obtain golf microspheres.

[0033] Step 5: The golf microspheres are sterilized and freeze...

Embodiment 2

[0036] Example 2, investigating the influence of the molecular weight ratio of materials on the preparation of golf microspheres.

[0037] Step 1: Dissolve 1 g of component A polylactic acid (molecular weight 100KD, 150KD, 200KD) and component B polycaprolactone (molecular weight 20KD, 40KD, 60KD and 100KD) in a mass ratio of 50:50 in In 20ml of dichloromethane component C, the concentration of the forming material is 5% biological mixture solution component D;

[0038] Step 2: Add component D to 200ml of 0.1% PVA stabilizer solution component E, and form emulsion component F by stirring and mixing;

[0039] Step 3: Continue stirring and mixing until the organic solution in component F is completely volatilized to form component G.

[0040] Step 4: Wash component G with water or buffer solution as required to remove the residual to obtain golf-shaped microspheres.

[0041] Step 5: The golf microspheres are sterilized and freeze-dried in an aseptic environment to obtain steri...

Embodiment 3

[0044] Example 3. Investigate the influence of the type and proportion of component A on the preparation of golf-type microspheres.

[0045]Step 1: Dissolve 1 g of different component A (including PLA, PLGA and a mixture of the above two materials in different proportions) and component B polycaprolactone (molecular weight 40KD) in a mass ratio of 50:50 in In 20ml of dichloromethane component C, the concentration of the forming material is 5% biological mixture solution component D;

[0046] Step 2: Add component D to 200ml of 0.1% PVA stabilizer solution component E, and form emulsion component F by stirring and mixing;

[0047] Step 3: Continue stirring and mixing until the organic solution in component F is completely volatilized to form component G.

[0048] Step 4: Wash component G with water or buffer solution as required to remove the residual to obtain golf-shaped microspheres.

[0049] Step 5: The golf microspheres are sterilized and freeze-dried in an aseptic envir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com