Method for regenerating iron phosphate waste

A technology for iron phosphate and waste materials, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve problems such as environmental pollution, impact on battery performance, improper disposal of waste materials, etc., and achieve the effect of low impurity content and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

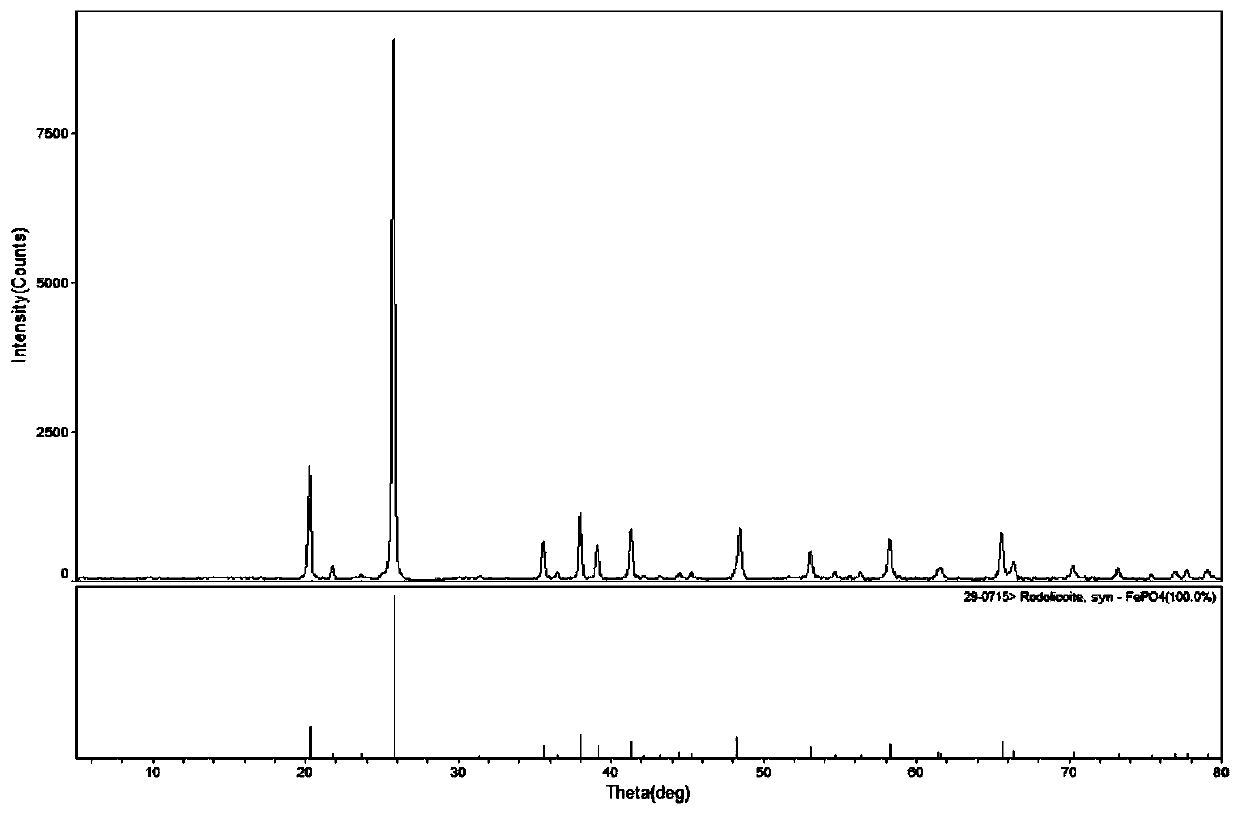

Image

Examples

Embodiment 1

[0035] Embodiment 1 of the present invention is: a kind of regeneration method of ferric phosphate waste, specifically comprises the following steps:

[0036] (1) Take by weighing 1000kg above-mentioned ferric phosphate waste I, add 5m 3 Add 504.10 kg of sulfuric acid (wt%=98%) solution to the water after stirring evenly, heat to 85°C, and after the iron phosphate is completely dissolved, filter to obtain solution A containing iron and phosphorus.

[0037] (2) Add 13.01 kg of phosphoric acid (wt%=85%) solution to solution A to obtain solution B containing iron and phosphorus, wherein the molar ratio of iron and phosphorus in solution B is 1:1.

[0038] (3) Under the condition that the stirring speed is 30r / min, add ammonia water to the solution B, adjust the pH value to 2.0, react at 100°C for 0.2h, and then separate the solid from the liquid, and wash the filter cake to obtain 2150kg of amorphous phosphoric acid Iron intermediate filter cake.

[0039] (4) The 2150kg amorpho...

Embodiment 2

[0040] Embodiment 2 of the present invention is: a kind of regeneration method of ferric phosphate waste, specifically comprises the following steps:

[0041] (1) Weigh 1kg of the above iron phosphate waste II, add it to 5L of water, stir evenly, add 848.5g of hydrochloric acid (wt%=30%) solution, heat to 60°C, and after the iron phosphate is completely dissolved, filter to obtain iron-containing Phosphorus solution A.

[0042] (2) Add 519.67g of iron sulfate (wt%=98%) solution to solution A to obtain solution B containing iron and phosphorus, wherein the molar ratio of iron and phosphorus is 1:0.9.

[0043] (3) Under the condition that the stirring speed is 200r / min, add ammonia water to the solution B, adjust the pH value to 2.5, react at 85°C for 1h, and then separate the solid from the liquid, and wash the filter cake to obtain 2150g of amorphous ferric phosphate Intermediate filter cake.

[0044](4) Put 2150g of amorphous ferric phosphate intermediate filter cake into 2...

Embodiment 3

[0045] Embodiment three of the present invention is: a kind of regeneration method of ferric phosphate waste, specifically comprises the following steps:

[0046] (1) Weigh 1kg of the above iron phosphate waste III, add it to 1L of water, stir well, add 646.2g of nitric acid (wt% = 68%), heat to 100°C, and after the iron phosphate waste is completely dissolved, filter to obtain iron-containing phosphorus solution A.

[0047] (2) Since the iron-phosphorus ratio in solution A is between 0.9 and 1.02, no iron and phosphorus sources are added in solution A, and solution A is directly used as solution B, wherein the molar ratio of iron to phosphorus is 1 :0.926.

[0048] (3) Under the condition that the stirring speed is 200r / min, add sodium carbonate to solution B, adjust the pH value to 2.3, react at 100°C for 2h, and then separate the solid from the liquid, and wash the filter cake to obtain 1850g of amorphous phosphoric acid Iron intermediate filter cake.

[0049] (4) Put 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com