Improved method of bleaching of metatitanic acid slurry and metatitanic acid

A technology of metatitanic acid and slurry, which is applied in the direction of titanium oxide/hydroxide, etc., can solve the problems of heavy waste water treatment load, influence on chroma, increase of b value, etc., and achieve reduction of sulfuric acid unit consumption, low overall cost, and saving resource effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

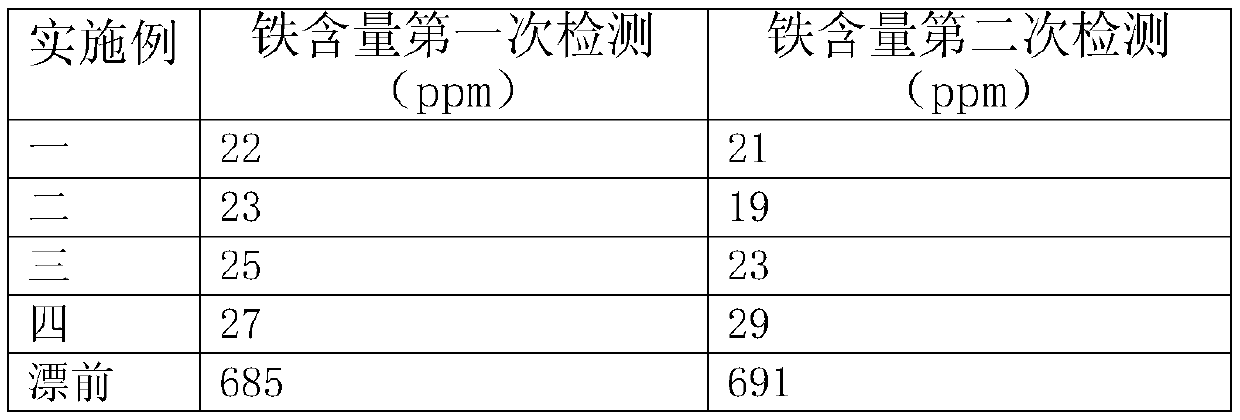

Embodiment 1

[0037] An improved method for bleaching metatitanic acid slurry, its specific steps are:

[0038] (1) Take metatitanic acid slurry 40m 3 Add in the reaction vessel, the solid content of the metatitanic acid slurry is 300g / L;

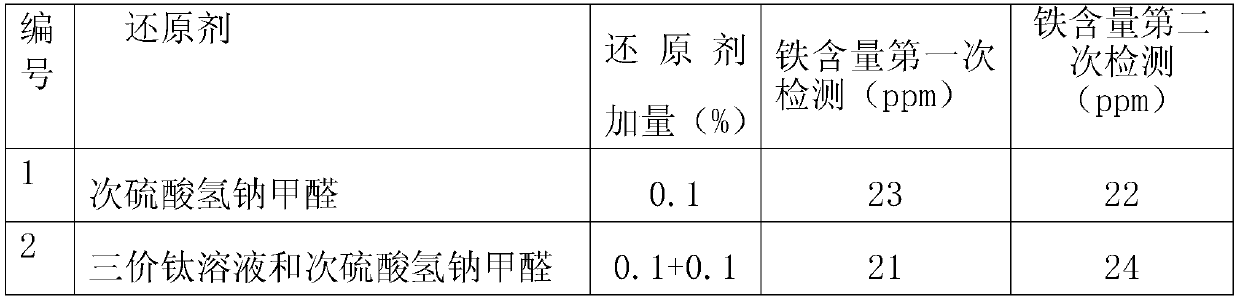

[0039] (2) add trivalent titanium solution 200L and sodium bisulfite formaldehyde 12Kg under stirring and carry out reduction reaction, meanwhile, need to control the mass content of free sulfuric acid in the reduction reaction to be 20g / L; The trivalent titanium added in the reduction reaction The quality of the trivalent titanium in the solution is 0.1% of the total titanium mass in the metatitanic acid slurry, and the addition of the sodium bisulfite formaldehyde is 0.1% of the total titanium mass in the metatitanic acid slurry; the stirring of the reduction reaction The frequency is 40r / min, and the stirring time is 48min;

[0040] (3) The product of the reduction reaction is filtered and washed to obtain bleached metatitanic acid; the washing refe...

Embodiment 2

[0042] An improved method for bleaching metatitanic acid slurry, its specific steps are:

[0043] (1) Take 1200mL of metatitanic acid slurry and add it into the reaction vessel. The solid content in the metatitanic acid slurry is 300g / L; then heat, add 60mL of seed crystals while heating and stir evenly, and control the addition of The solid content of the seed crystal is 100g / L;

[0044] (2) Heating, when the temperature in the reaction vessel is 60°C, add 6 mL of trivalent titanium solution and 0.36 g of sodium bisulfite formaldehyde under stirring to carry out the reduction reaction and keep the temperature in the reaction vessel at 60°C. Control the mass content of free sulfuric acid in the reduction reaction to be 15g / L; The quality of the trivalent titanium in the trivalent titanium solution added in the reduction reaction is 0.1% of the total titanium mass in the metatitanic acid slurry, and the The amount of hydrogen sodium formaldehyde added is 0.1% of the total tita...

Embodiment 3

[0047] An improved method for bleaching metatitanic acid slurry, its specific steps are:

[0048] (1) get metatitanic acid slurry 1200mL and add in the reaction vessel, the solid content in the metatitanic acid slurry is 280g / L;

[0049] (2) Heating, until the temperature in the reaction vessel is 55°C, add 22.4mL of trivalent titanium solution and 1.68g of sodium bisulfite formaldehyde under stirring to carry out the reduction reaction and keep the temperature in the reaction vessel at 60°C, at the same time, It is necessary to control the mass content of free sulfuric acid in the reduction reaction to be 25g / L; the quality of the trivalent titanium in the trivalent titanium solution added in the reduction reaction is 0.4% of the total titanium mass in the metatitanic acid slurry. The amount of sodium bisulfate formaldehyde added is 0.05% of the total titanium mass in the metatitanic acid slurry; the stirring frequency of the reduction reaction is 20r / min, and the stirring ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com