A treatment method for improving the centrifugal dehydration efficiency of anaerobic sludge

A treatment method and technology for anaerobic sludge, applied in water/sludge/sewage treatment, sludge treatment, biological sludge treatment, etc. The effect of reducing work intensity and workload, reducing processing costs, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

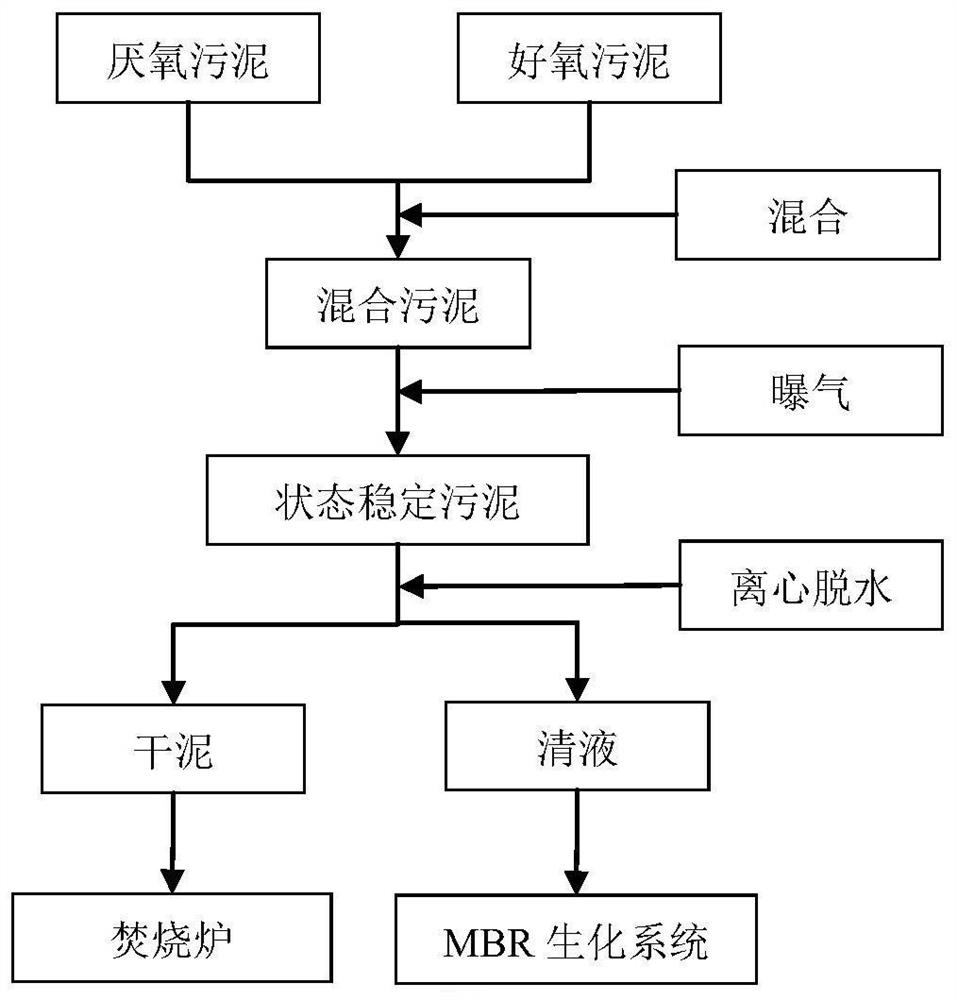

[0021] A treatment method for improving the centrifugal dehydration efficiency of anaerobic sludge, the treatment process flow chart is as follows figure 1 shown, including the following steps:

[0022] S1. According to the volume ratio of the anaerobic sludge and the aerobic sludge is 1:15, the anaerobic sludge in the anaerobic system and the aerobic sludge in the MBR system are mixed to obtain mixed sludge.

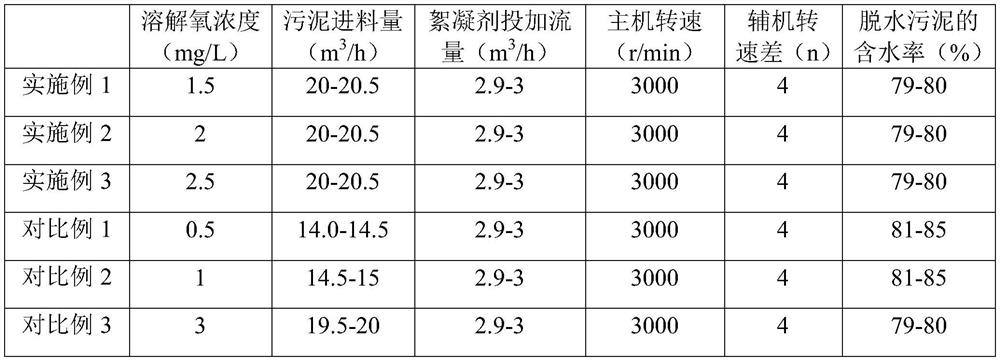

[0023] S2. Put the mixed sludge in step S1 in the aeration tank, and perform aeration under the condition of stirring at a rotating speed of 30r / min. Specifically, first aerate for 1 hour, then stop the aeration for 1 hour, and use this as the basic cycle. Cycle intermittent aeration until the dissolved oxygen concentration in the mixed sludge is stable at 1.5mg / L, and the treatment of anaerobic sludge is completed. In this step, there are 125 aeration discs at the bottom of the aeration tank, and the gas flow rate of a single aeration disc is 1.5-2m 3 / h, and there a...

Embodiment 2

[0025] A treatment method for improving the centrifugal dehydration efficiency of anaerobic sludge is basically the same as that of Example 1, the only difference being that in Step S2 of Example 2, the concentration of dissolved oxygen in the mixed sludge is stabilized at 2.0 mg / L.

Embodiment 3

[0027] A treatment method for improving the centrifugal dehydration efficiency of anaerobic sludge is basically the same as that of Example 1, the only difference being that in Step S2 of Example 3, the dissolved oxygen concentration in the mixed sludge is stabilized at 2.5 mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com