Complex enzyme for degumming and fixation of natural colored silk and application method of complex enzyme

A technology of colored silk and compound enzymes, applied in the field of natural colored silk processing, can solve the problems of difficulty in weaving, loss of pigment damage, stiff fabrics, etc., and achieves the effect of eliminating dyeing and finishing processes and achieving stable quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

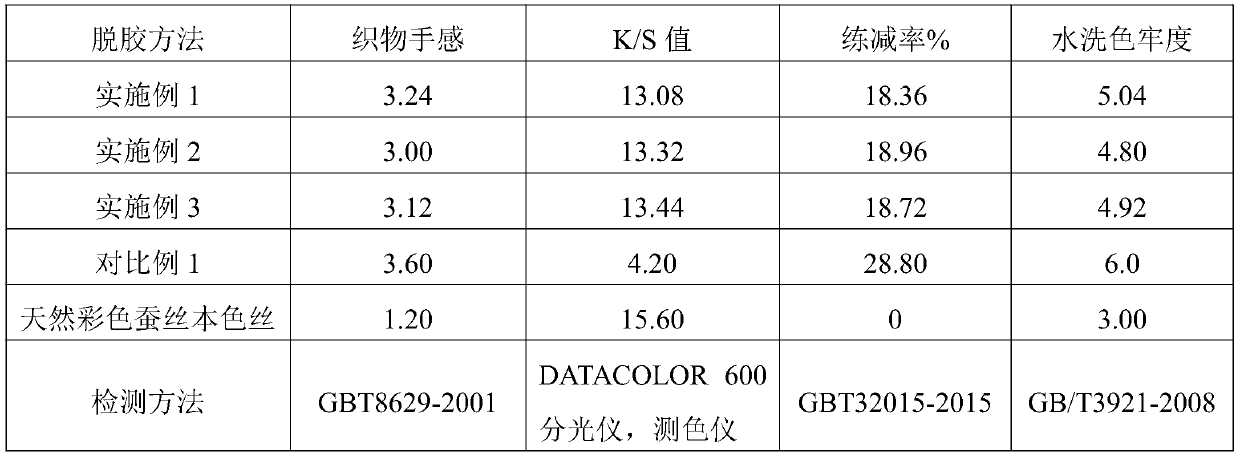

Examples

Embodiment 1

[0032] A compound enzyme for degumming and color-fixing natural colored silk, said compound enzyme is composed of biological enzyme A and biological enzyme B, wherein:

[0033] The biological enzyme A includes the following components in weight percent: papain 1%, bromelain 1%, neutral protease 0.5%, lipase 0.1%, water 97.4%;

[0034] The biological enzyme B includes the following components in weight percent: sulfhydryl oxidase 1%, protein disulfide bond isomerase 0.3%, water 98.7%;

[0035] The specific method of using the compound enzyme for degumming and color-fixing natural colored silk comprises the following steps:

[0036] 1. Soak 1,000 grams of natural colored raw silk in 30°C water for 40 minutes to swell the sericin on the surface of the natural colored raw silk. The prime coat protein is exposed, forming an enzyme entry channel.

[0037] 2. Drain the impregnating liquid in step 1, wash it once with deionized water, and remove the soluble protein in the solution a...

Embodiment 2

[0041] A compound enzyme for degumming and color-fixing natural colored silk, said compound enzyme is composed of biological enzyme A and biological enzyme B, wherein,

[0042] The biological enzyme A includes the following components in weight percent: 5% papain, 5% bromelain, 2% neutral protease, 2% lipase, 5% benzisothiazolone (preservative), and 81% water;

[0043] The biological enzyme B includes the following components in weight percent: sulfhydryl oxidase 5%, protein disulfide bond isomerase 2%, benzisothiazolone 5%, water 88%;

[0044] The specific method of using the compound enzyme for degumming and color-fixing natural colored silk comprises the following steps:

[0045]1. Soak 1,000 grams of natural colored raw silk in water at 50°C for 40 minutes to swell the sericin on the surface of the natural colored raw silk. The prime coat protein is exposed, forming an enzyme entry channel.

[0046] 2. Drain the impregnating liquid in step 1, wash it once with deionized ...

Embodiment 3

[0050] A compound enzyme for degumming and color-fixing natural colored silk, said compound enzyme is composed of biological enzyme A and biological enzyme B, wherein,

[0051] The biological enzyme A comprises the following components in weight percent: papain 10%, bromelain 10%, neutral protease 5%, lipase 3%, sorbitol (preservative) 5%, water 67%;

[0052] The biological enzyme B includes the following components in weight percent: sulfhydryl oxidase 10%, protein disulfide bond isomerase 5%, sorbitol 5%, water 80%;

[0053] The specific method of using the compound enzyme for degumming and color-fixing natural colored silk comprises the following steps:

[0054] 1. Soak 1,000 grams of natural colored raw silk in water at 80°C for 40 minutes to swell the sericin on the surface of the natural colored raw silk. The prime coat protein is exposed, forming an enzyme entry channel.

[0055] 2. Drain the impregnating liquid in step 1, wash it once with deionized water, and remove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com